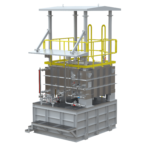

Series 8400

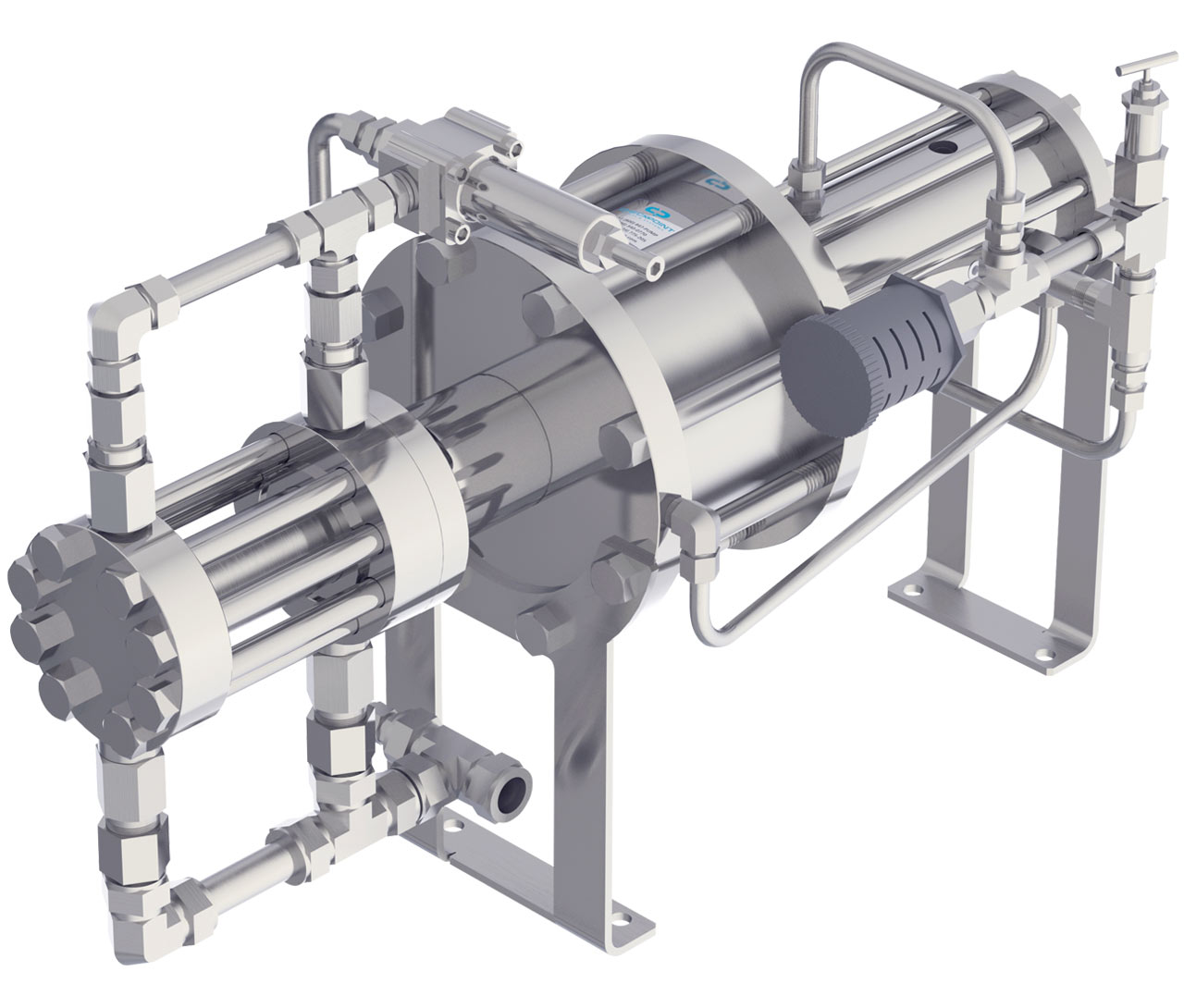

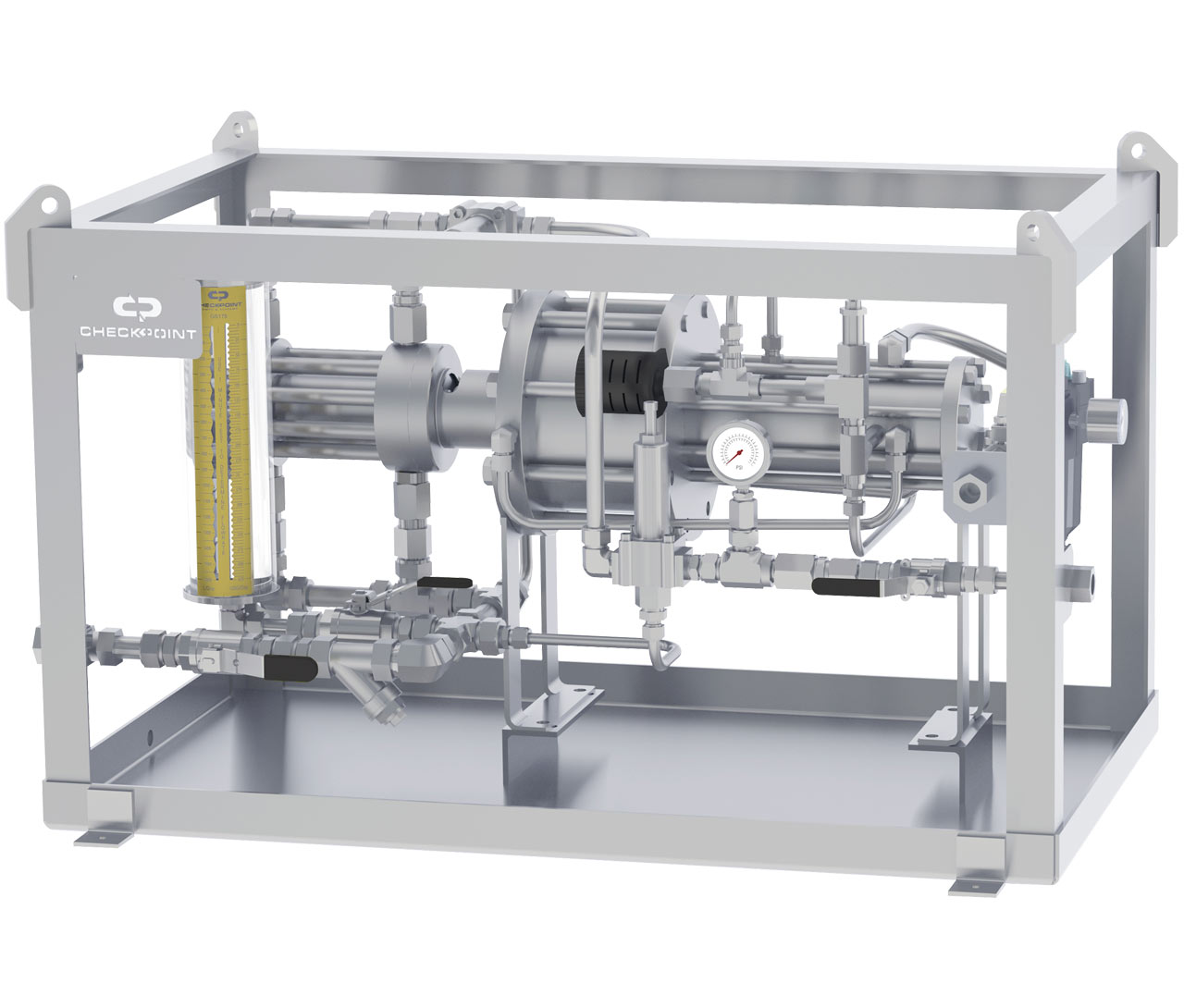

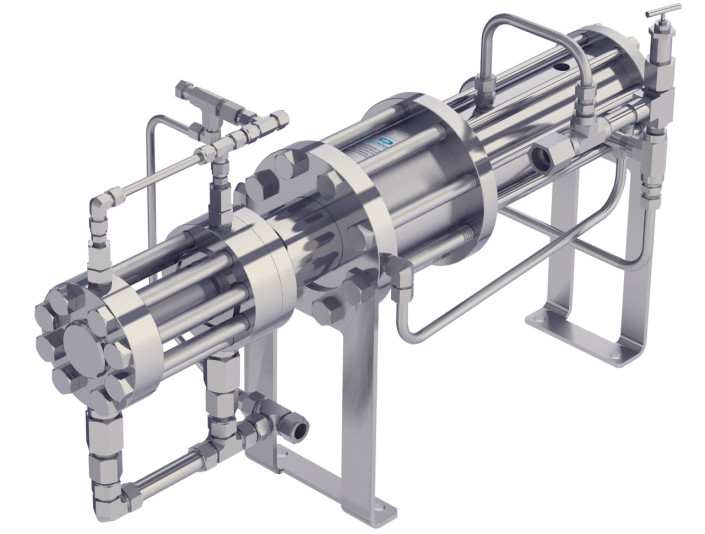

Pneumatic Plunger Pump

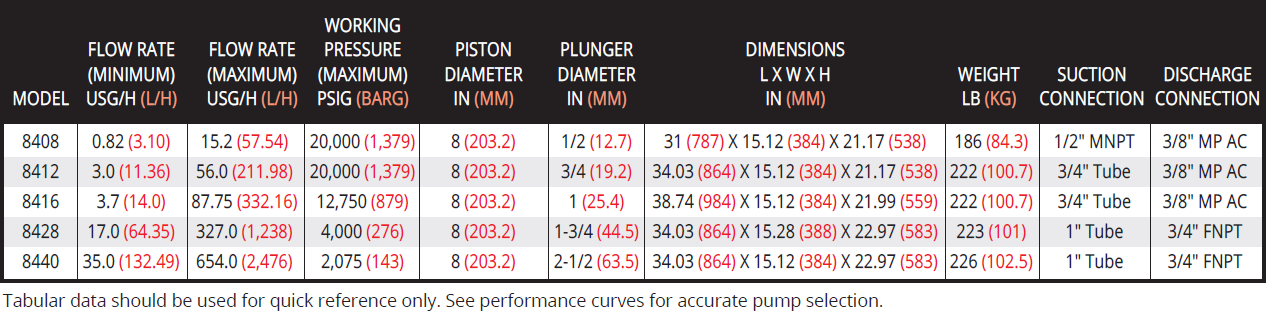

CheckPoint’s Series 8400 pump delivers between 0.83 – 585 USG/H (3.14 – 2,214.47 L/H) and can reliably inject into pressures up to 20,000 PSIG (1,379 BARG).

From the isolated chemical head to the switching valve to the materials of construction, CheckPoint’s Series 8400 pump was developed for continuous, accurate, and reliable injection in harsh offshore and remote locations. No compromises were made. We designed this pump for vital, mission-critical chemicals like methanol, drag reducer, and other expensive, hazardous, and corrosive production compounds.

Operating Manual

Order Guide

Rentals

In order to meet a wide variety of chemical compatibility needs, wetted parts are available in an array of materials, such as 316L SS, Hastelloy C-276, Duplex 2505, Super Duplex 2507, ceramic and titanium, and seals are available in Viton, HNBR, FKM, and FFKM. All construction materials are compatible with sour gas according to NACE MR0175 and ISO 15156. CheckPoint pumps do not contain any springs and have fewer moving parts than any other pneumatic pump in the industry, resulting in minimal wear, effective maintenance, and ultimately an increased life span.