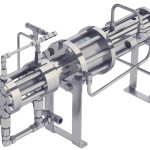

Series 1500

Pneumatic Plunger Pump

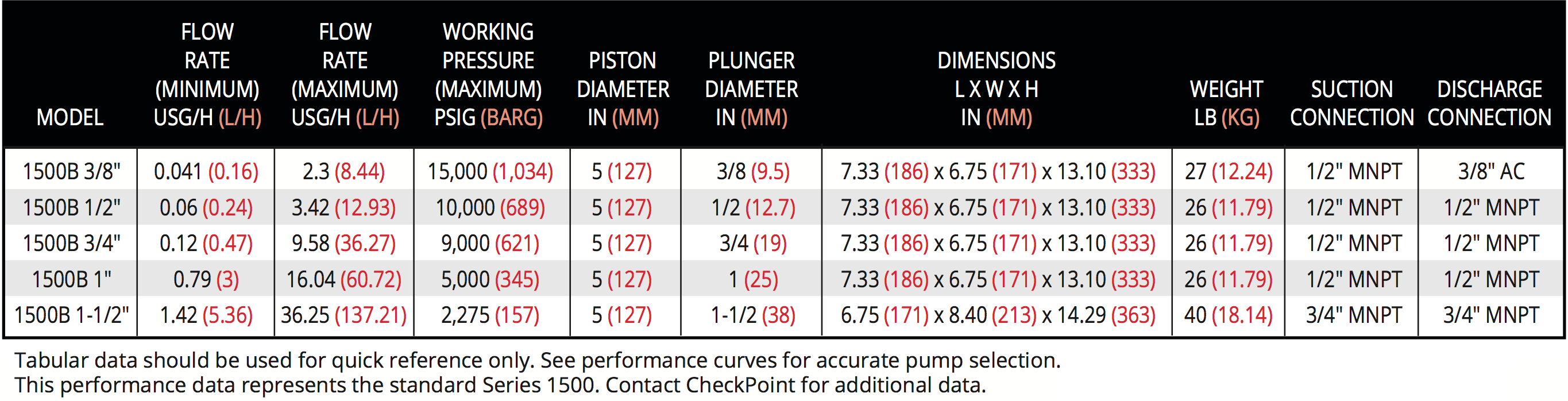

CheckPoint’s Series 1500 pump delivers up to 36.25 USG/H (137.21 L/H) and can reliably inject into pressures up to 15,000 PSIG (1,034.0 BARG).

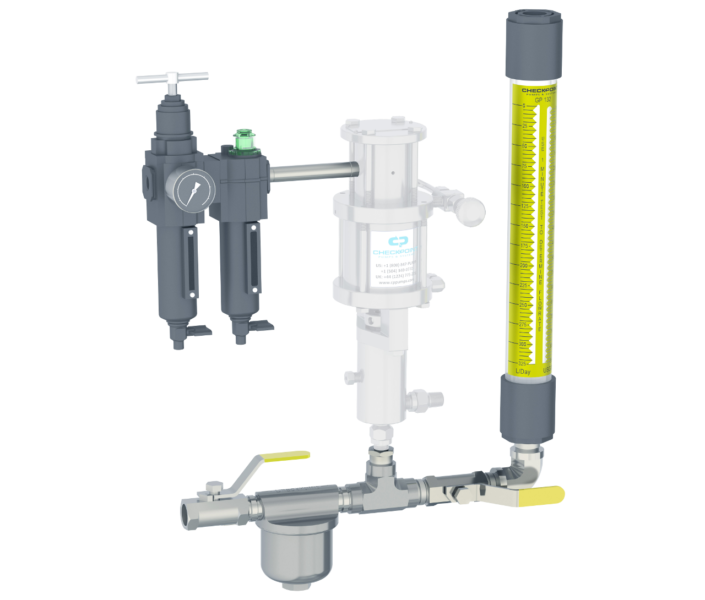

CheckPoint’s modularly designed chemical heads and range of plunger sizes meet a wide variety of injection applications. Our pumps maintain unparalleled chemical resistance due to the essential integration of high-quality, proprietary seal materials. In order to meet a wide variety of chemical compatibility needs, wetted parts are available in an array of materials, such as 316 SS, Hastelloy C-276, Duplex 2205, Super Duplex 2507, PVC, ceramic and titanium, and seals are available in Viton, HNBR, FKM, and FFKM. All construction materials are compatible with sour gas according to NACE MRO175 and ISO 15156.

Performance Data

Operating Manual

Order Guide

Sales Brochure

Rentals

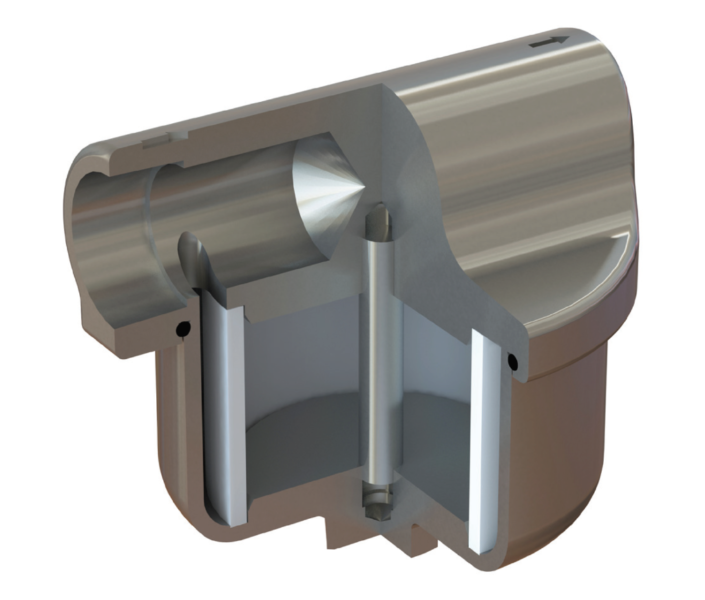

CheckPoint’s positive displacement, reciprocating chemical injection pumps are specifically designed for, and extensively proven in, demanding oil and gas production applications worldwide. Our pumps are utilized in various industries, such as pulp, water treatment, fertilizer dosing, paper, and fluid processing applications, where precise delivery is operationally paramount. The pneumatic motor, composed entirely 316L SS, remains isolated from the wet end and is dependably able to run on pressurized gas or liquid without stalling. Check-Point’s double-acting design eliminates a return spring, which greatly increases repeatability and reliability over time.

Performance Data

| Series 1500 | |

|---|---|

| Cycle Rate / Minute (1) | 0.75 – 85 (3) |

| Supply Pressure | 20 – 200 psig (1.4 – 13.8 barg) |

| Piston Diameter | 5.00 in (127 mm) |

| Stroke Length(3) | 1.00 in (25 mm) |

| Weight | 20 lbs (9.1 kg) |

| Height | 13.5 in (343 mm) |

| Turndown Ratio (max / min cycle rate) | 113 |

1. Series 1500 Gas Recovery pumps have a max cycle rate / min of 65.

2. “Short Stroke” models have a stroke length of 0.5 in (13 mm)