Series HDA

Electric Diaphragm Pump

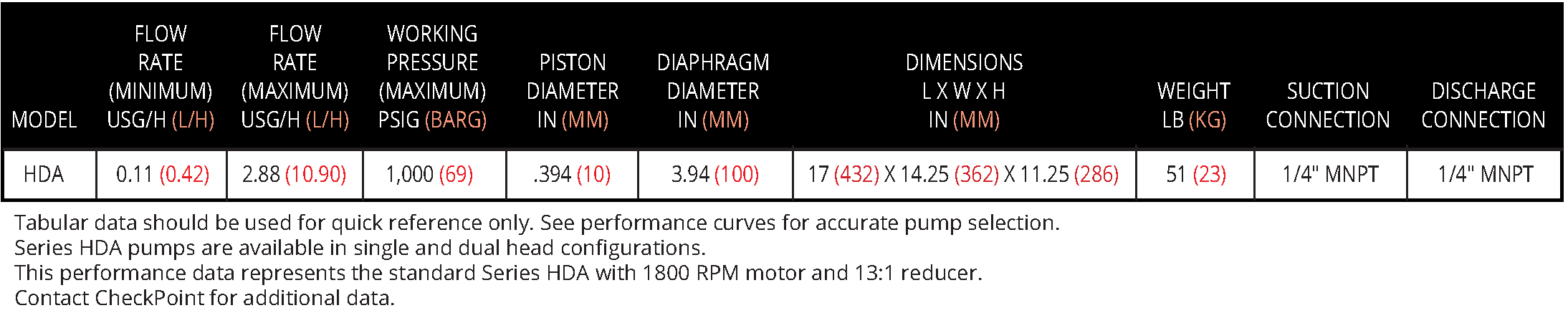

CheckPoint’s Series HDA pump delivers between 0.11 – 2.88 USG/H (0.42 – 10.90 L/H) and can reliably inject into pressures up to 1,000 PSIG (69 BARG).

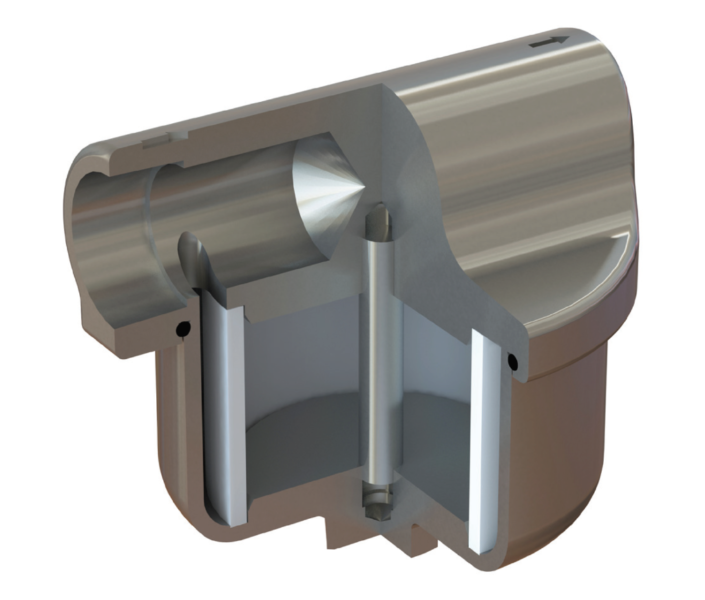

CheckPoint’s Series HDA chemical injection pump features a “sandwich” diaphragm set consisting of three stainless steel disks constrained between the pump’s chemical head and hydraulic body. These disks can flex quite easily due to their thickness, ensuring a minimal chance of failure. In the event that one of the diaphragms does fail, the pump will continue to operate without cross-contamination between the hydraulic oil and the chemical.

The HDA’s hydraulic plunger and bushing are constructed of strong ceramic materials, guaranteeing long life, low wear, and repeatable, consistent chemical injection throughout the lifetime of the pump. Its pump head has several safety and indication features, including a diaphragm rupture detection system which provides multiple options for indication, including a popup tattletale, gauge, or electrical signal, and also incorporates a pressure-limiting internal relief valve with a tattletale indicator, which allows the user to see if an event has occurred.

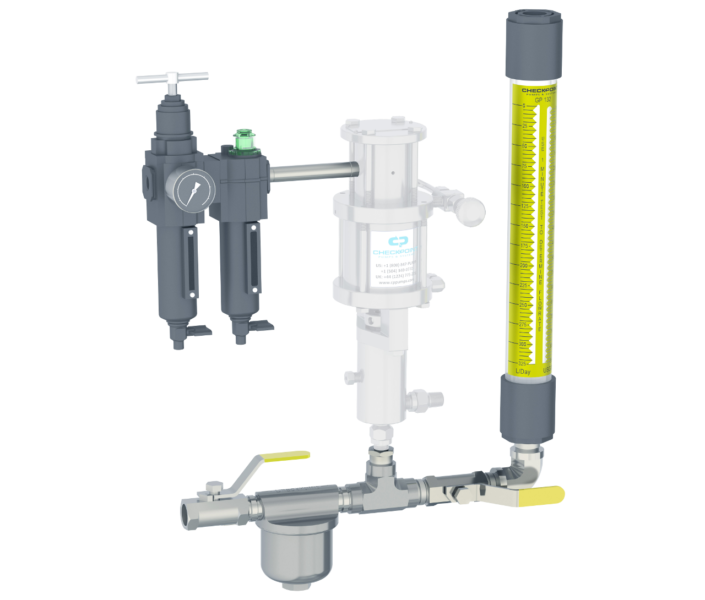

The Series HDA pump delivers up to 2.88 USG/H (10.90 L/H) and can reliably inject into pressures up to 1,000 PSIG (69 BARG). CheckPoint’s expertly designed diaphragm pump maintains its durability, versatility, and unparalleled chemical resistance due to its metallic sandwich design and the essential integration of high-quality, proprietary seal materials. In order to meet a wide variety of chemical compatibility needs and applications, wetted parts are available in 316 SS, and seals are available in Viton, HNBR, FKM, and FFKM. All wet end construction materials meet the requirements of NACE MRO175 and ISO 15156.