Why Are Injection Pumps Essential for Engine Performance?

Injection pumps play a crucial role in enhancing engine performance. These devices ensure precise fuel delivery, contributing to efficiency and power. According to a report from the Society of Automotive Engineers, optimal fuel injection can improve engine efficiency by up to 30%. This impressive figure highlights the need for reliable injection pumps in modern engines.

Experts in the field emphasize the significance of these pumps. Peter Johnson, a leading engineer in fuel systems, stated, “Without efficient injection pumps, even the best engines can underperform.” This insight underscores the importance of maintaining these components.

Despite advancements, issues can arise. Some pumps may experience wear over time, leading to diminished performance. Regular checks and maintenance are essential to address these challenges. The intricate design of injection pumps requires a balance between accuracy and durability. Disregarding these factors can seriously hinder engine function.

The Role of Injection Pumps in Internal Combustion Engines

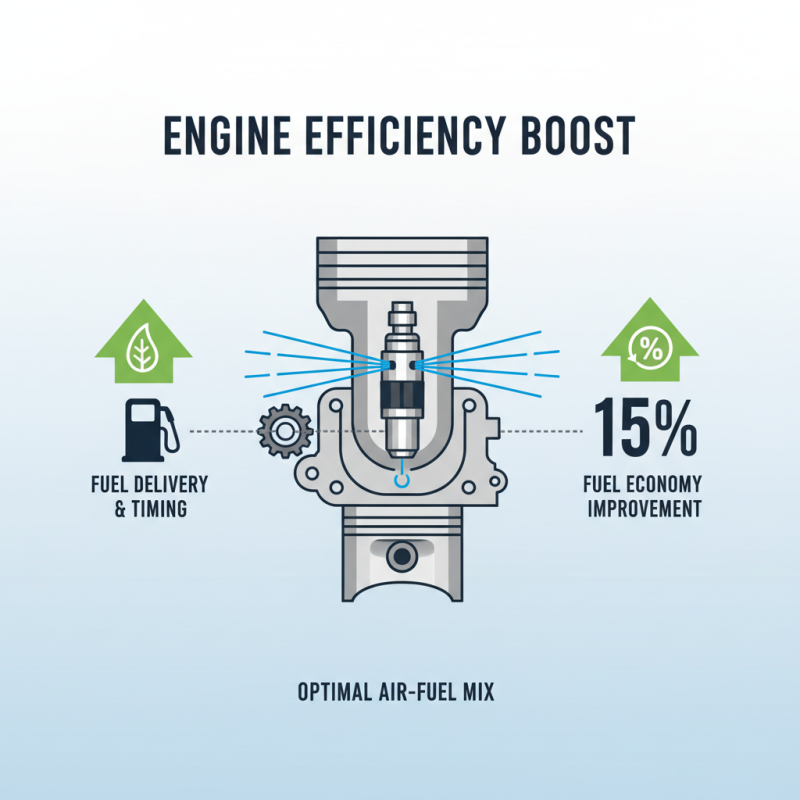

Injection pumps play a critical role in the performance of internal combustion engines. They are responsible for delivering fuel into the combustion chamber at precise intervals. This fueling process ensures optimal air-fuel mixtures, which significantly enhances engine efficiency. According to recent industry reports, engines equipped with high-quality injection pumps show improvements in fuel economy by approximately 15%. That’s a crucial factor for many vehicle owners.

However, not all injection pumps are created equal. Inconsistent fuel delivery can lead to incomplete combustion, resulting in reduced engine power and increased emissions. Reports indicate that engines with poorly functioning pumps may experience a drop in efficiency by up to 30%. This highlights the importance of regular maintenance and inspection. Dirty fuel filters or worn components can deteriorate pump performance, leading to both operational and financial losses.

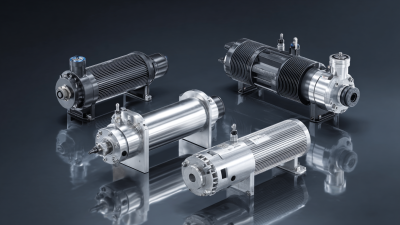

Increased performance demands also place additional strain on injection pumps. As engines become more powerful, the need for precision becomes crucial. Some engines now operate under higher pressures and temperatures than before. This can lead to premature wear of the injection system. It’s essential for manufacturers to focus on developing more resilient components to mitigate these issues. Understanding these complexities can lead to significant improvements in engine reliability and longevity.

How Injection Pumps Optimize Fuel Delivery Efficiency

Injection pumps play a vital role in optimizing fuel delivery efficiency in engines. These components ensure that fuel reaches the engine at the correct pressure and quantity. Properly calibrated injection pumps can improve combustion, making the engine run smoother and more efficiently. When fuel is delivered correctly, it enhances performance and reduces emissions. However, even the best systems can face issues over time.

One common problem is wear and tear. If an injection pump isn’t maintained, it may not deliver fuel accurately. This can lead to incomplete combustion, where fuel fails to burn properly. The result? Suboptimal performance and increased fuel consumption. Regular check-ups can prevent these scenarios but often go overlooked until issues arise.

Another challenge includes varying fuel qualities. Not all fuels perform the same in every engine. An injection pump needs to adapt to these differences. Sometimes, it struggles, leading to trackable inefficiencies. Owners might notice changes in acceleration or fuel economy. Evaluating and understanding these impacts can help in making informed maintenance decisions.

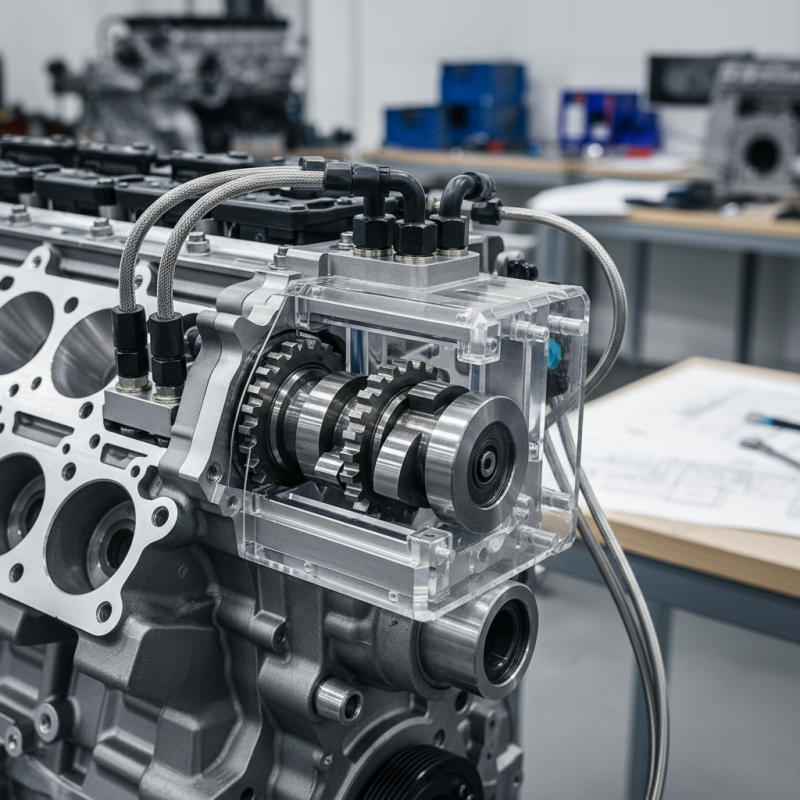

Impact of Injection Pump Design on Engine Performance

The design of injection pumps plays a critical role in engine performance. An optimized pump enhances fuel atomization. This leads to better combustion efficiency. According to recent studies, engines with advanced injection pump designs can achieve up to 10% more power output. They also emit fewer pollutants, improving environmental compliance.

Fuel delivery timing is another key factor. Research indicates that precise timing can raise fuel efficiency by around 5%. If the timing is off, it can lead to engine knock and excessive vibration. Important characteristics include the pump's pressure output and flow rate. An efficient pump should deliver fuel consistently and at the right pressure.

Tips: Regular maintenance of injection pumps can prevent performance drops. Check for leaks and ensure proper fuel filtration. Consider monitoring your engine’s performance metrics closely. Any irregularities might point to pump inefficiencies. Remember, neglecting this aspect can lead to costly repairs down the line, which is a reflection of poor design choices.

Common Issues with Injection Pumps and Their Effects on Engines

Injection pumps play a crucial role in delivering fuel to an engine. However, they can develop issues that affect performance. One common problem is fuel leakage. This reduces fuel efficiency and causes poor engine performance. In severe cases, it can lead to complete engine failure.

Clogged filters are another major concern. When the filters block, fuel cannot flow properly. This can cause misfires and a rough idle. Regular maintenance is essential to prevent this issue. Some drivers ignore this until they notice power loss.

Moreover, injection pumps may fail due to wear and tear. High mileage vehicles often face this problem. Symptoms include hard starting and excessive smoke. Ignoring these signs may lead to costly repairs. Pay attention to your engine's performance. Regular checks can save time and money in the long run.

Maintaining Injection Pumps for Enhanced Engine Longevity

Maintaining injection pumps is crucial for the overall health of your engine. These pumps are responsible for delivering fuel precisely when needed, ensuring optimal combustion. A well-functioning injection pump can significantly enhance fuel efficiency and reduce emissions. However, neglect can lead to performance issues and costly repairs.

To keep your injection pump in top shape, regular inspections are key. Look for signs of wear, leaks, or unusual noises. These indicators often signal the need for repairs. Clean fuel is essential. Contaminated fuel can clog the injectors and damage the pump. Always use high-quality fuel and replace filters as needed.

Tips: Regularly check the fuel filter. This small task can save you money. Don't ignore small problems; they can escalate quickly. Replace your fuel lines if they show signs of wear. It's a simple step that makes a big difference. Remember, maintenance can extend the life of your engine and improve performance. Keeping an eye on your injection pump is not just smart; it’s essential.

Related Posts

-

How to Choose the Right Injection Pumps for Your Needs

-

Top 2025 Pressure Pumps: Innovative Solutions for Every Need

-

Top 10 Benefits of Using Hydraulic Oil in Machinery?

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

Why Choose a Chemical Metering Pump for Precise Liquid Handling in Your Industry

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.