Understanding the Different Types of Motor Pumps and Their Applications in Various Industries

In today's industrial landscape, motor pumps play a crucial role across a wide array of applications, catering to sectors such as agriculture, construction, and manufacturing. According to a recent market report by Research and Markets, the global motor pump market is projected to reach USD 57 billion by 2026, growing at a CAGR of 4.8% from 2021 to 2026. This growth is driven by the increasing demand for efficient fluid transfer and management solutions. Understanding the different types of motor pumps, from centrifugal to diaphragm pumps, and their specific applications is essential for industry stakeholders aiming to optimize their operations and improve productivity. By leveraging the right motor pump technology, businesses can not only enhance their operational efficiency but also contribute to sustainability efforts through energy conservation and reduced water waste.

Types of Motor Pumps: A Comprehensive Overview for Industrial Applications

Motor pumps are essential components across various industries, providing crucial fluid movement capabilities. Their applications range from electric vehicle traction systems to oil and gas pump health management. Understanding the different types of motor pumps can help industries maximize their operational efficiencies and ensure reliable performance.

For instance, traction motors used in electric vehicles focus on maximizing mechanical efficiency, allowing for improved energy consumption and vehicle performance. Additionally, integrating Artificial Intelligence for prognostic health management in the oil and gas sector can significantly reduce downtime and maintenance costs by identifying potential issues before they escalate.

When choosing motor pumps for specific applications, consider the latest advancements in energy storage systems and integrating hybrid renewable energy sources for water pumping. These innovations not only enhance efficiency but also promote sustainability. A tip for selecting the right motor pump is to investigate different lubrication options, especially for high-temperature applications, as the right lubricant can significantly affect pump performance and longevity. Always conduct thorough research and apply systematic selection methodologies for optimal results.

Understanding the Different Types of Motor Pumps and Their Applications

Exploring Positive Displacement Pumps: Mechanism and Usages

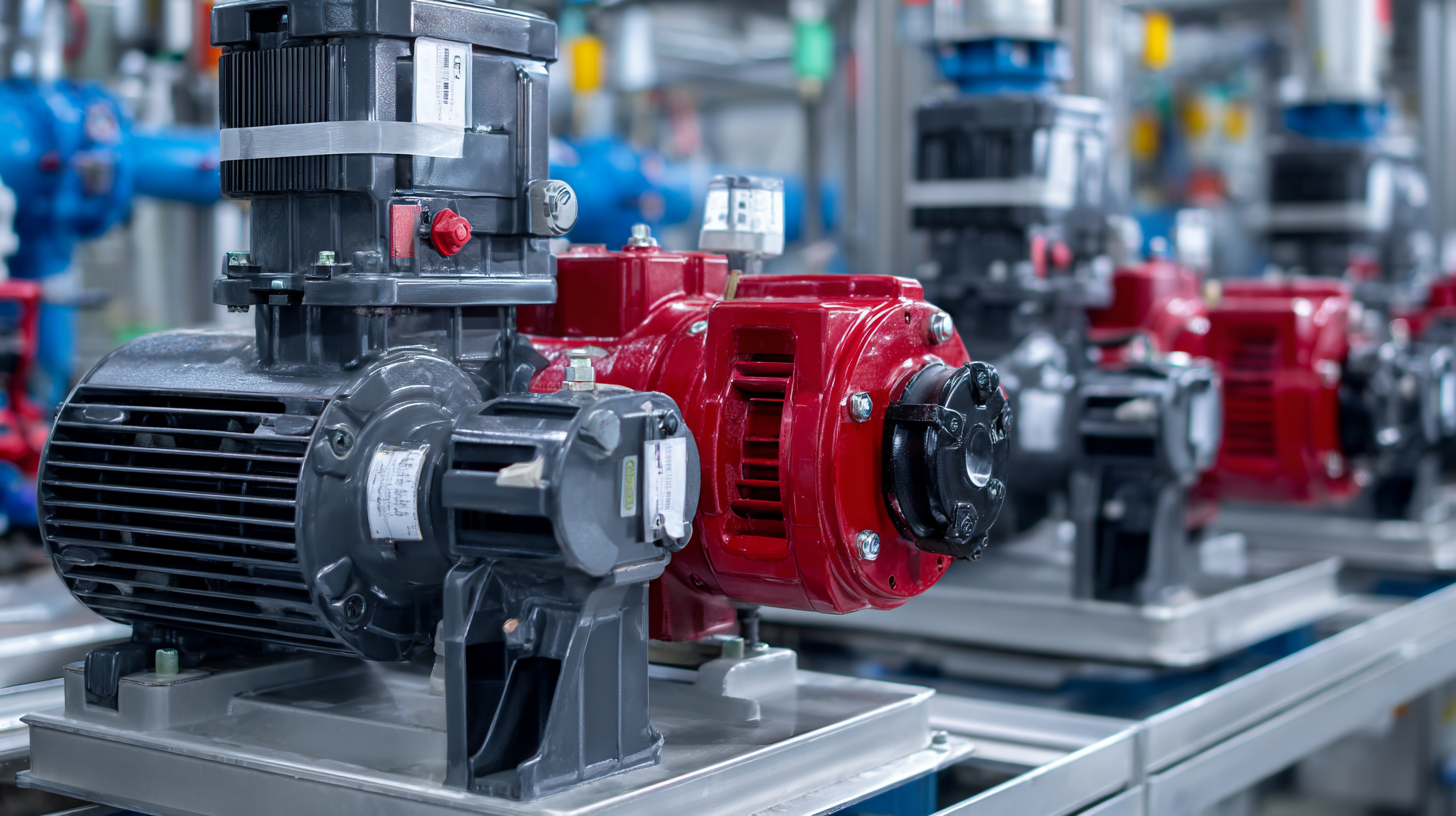

Positive displacement pumps are integral to numerous industries, offering reliable performance for a variety of applications. These pumps work by trapping a fixed amount of fluid and forcing it through the discharge pipe, making them ideal for handling viscous fluids and maintaining consistent flow rates. They are commonly used in oil and gas, food processing, and chemical manufacturing, where precise fluid control is crucial.

When selecting a positive displacement pump, it’s essential to consider the specific requirements of your application. For instance, the viscosity of the fluid and the desired flow rate will greatly influence the type of pump you choose. Additionally, ensure that the materials used in the pump are compatible with the fluids you'll be handling to avoid corrosion and ensure longevity.

**Tip:** Regular maintenance is key to the performance of positive displacement pumps. Performing routine inspections and replacing worn-out seals and gaskets can prevent leaks and extend the life of the pump. **Tip:** Proper installation is crucial; ensure that the pump is mounted securely to reduce vibrations that can lead to premature wear.

Understanding the Different Types of Motor Pumps and Their Applications in Various Industries - Exploring Positive Displacement Pumps: Mechanism and Usages

| Pump Type | Mechanism | Applications | Industries | Advantages |

|---|---|---|---|---|

| Gear Pump | Uses gears to pump fluid by displacement. | Fuel transfer, hydraulic applications. | Automotive, manufacturing. | Consistent flow, good for high viscosity fluids. |

| Diaphragm Pump | Uses a diaphragm to create a vacuum that draws fluid. | Chemical transfer, wastewater treatment. | Chemical processing, pharmaceuticals. | Self-priming, can handle corrosive fluids. |

| Piston Pump | Uses a piston to move fluid through a chamber. | High-pressure applications, injection molding. | Oil and gas, chemical industries. | High efficiency, capable of high pressures. |

| Progressive Cavity Pump | Uses a rotating helical screw to move fluid. | Sludge and slurry transfer, food processing. | Waste management, food and beverage. | Handles viscous fluids well, smooth flow output. |

| Peristaltic Pump | Uses rollers to compress a flexible tube, pushing liquid forward. | Metering, dosing, sterile applications. | Pharmaceuticals, food processing. | No contamination, easy maintenance. |

Understanding Centrifugal Pumps: Benefits and Industry Applications

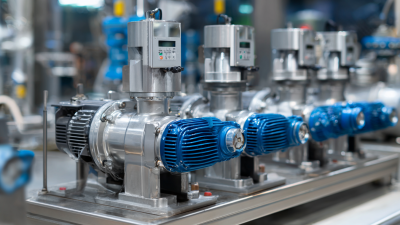

Centrifugal pumps are a crucial component in various industries, known for their efficiency and versatility. They operate by converting rotational energy, typically from an electric motor, into hydrodynamic energy, allowing for the transport of fluids through pipelines. One of the main benefits of centrifugal pumps is their ability to handle high flow rates with relatively low operational costs. This makes them ideal for applications in water treatment, chemical processing, and oil refining, where stable and continuous fluid movement is essential.

Centrifugal pumps are a crucial component in various industries, known for their efficiency and versatility. They operate by converting rotational energy, typically from an electric motor, into hydrodynamic energy, allowing for the transport of fluids through pipelines. One of the main benefits of centrifugal pumps is their ability to handle high flow rates with relatively low operational costs. This makes them ideal for applications in water treatment, chemical processing, and oil refining, where stable and continuous fluid movement is essential.

In addition to their energy efficiency, centrifugal pumps are available in various designs to accommodate different fluid characteristics. For example, they can effectively manage clean water, slurries, and even corrosive liquids, making them suitable for use in pharmaceuticals and food processing. Their adaptability to different environments and ease of maintenance enhance their attractiveness to industries looking for reliable pumping solutions. As industries advance, the role of centrifugal pumps will inevitably expand, driving innovation and improved performance across multiple applications.

Comparing Submersible and Inline Pumps: Key Features and Differences

When discussing motor pumps, particularly submersible and inline pumps, it’s essential to recognize their distinct features and applications. Submersible pumps are designed to operate underwater, making them ideal for applications such as dewatering, wastewater management, and groundwater extraction. According to a report by ResearchAndMarkets, the global submersible pumps market is projected to grow at a CAGR of 5.1% from 2020 to 2026, highlighting their increasing demand in industries such as oil and gas and municipal water supply.

In contrast, inline pumps are typically installed above the fluid they are pumping and are commonly used in heating and cooling systems, water treatment facilities, and chemical processing. Their design allows for a compact installation and easy maintenance, leading to increasing popularity in industrial applications. The Global Insight report emphasizes that the inline pump market is expected to reach $10 billion by 2025, driven by the need for energy-efficient solutions in various sectors. Understanding the differences in application and efficiency between these pump types is crucial for industries seeking optimal performance and resource management.

Selecting the Right Motor Pump for Your Industry Needs: A Practical Guide

Selecting the right motor pump for your industrial needs can significantly impact efficiency and productivity. According to a report by MarketsandMarkets, the global pump market is projected to reach $100 billion by 2025, driven by advancements in technology and increased demand across sectors such as oil and gas, water treatment, and agriculture. Understanding the various types of motor pumps available—including centrifugal, positive displacement, and submersible pumps—can help businesses make informed decisions tailored to their specific applications.

For instance, centrifugal pumps are commonly used in water treatment facilities and agricultural irrigation due to their efficiency in handling large volumes of fluid. Conversely, positive displacement pumps, favored for their ability to handle thick fluids or slurries, find applications in the food and beverage industry, where maintaining fluid quality is crucial. As per a review by the Hydraulic Institute, selecting a pump with the correct specifications, such as flow rate and head requirements, can improve overall operational performance by up to 30%, highlighting the importance of choosing the right motor pump for your industrial requirements.

Related Posts

-

Evaluating Cost-Effectiveness: A Comparative Analysis of Pump Rentals vs. Purchasing Equipment

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.