Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

In the realm of industrial applications, fluid pumps play a crucial role in the efficient movement of liquids and slurries across various sectors, including manufacturing, chemical processing, and water treatment. With the global fluid pumps market projected to reach USD 57.32 billion by 2027, growing at a CAGR of 4.8%, understanding the diverse types and functionalities of these pumps becomes essential for industry stakeholders.

Market research indicates that centrifugal and positive displacement pumps are among the most prominent types, each serving unique purposes depending on flow requirements and the nature of the fluid being transferred.

As technology evolves, the integration of smart pump systems is revolutionizing operational efficiency, offering insights into maintenance needs and usage patterns. This blog will delve into the key types of fluid pumps, their applications, and critical market insights that can guide manufacturers and engineers in making informed decisions.

Types of Fluid Pumps: A Comprehensive Overview for Industrial Applications

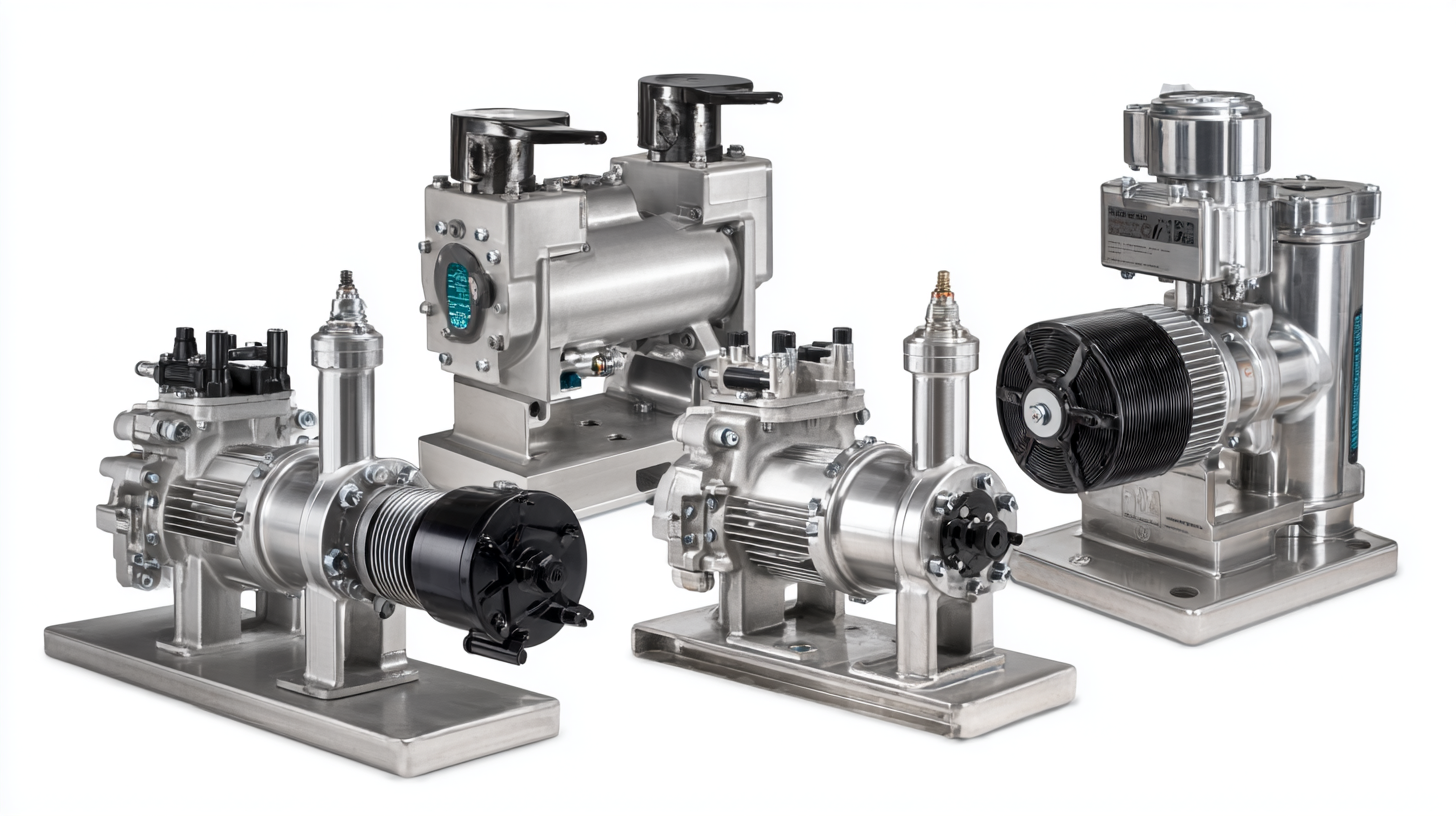

In industrial applications, fluid pumps play a crucial role in various processes, ranging from transferring fluids to maintaining system pressures. Understanding the types of fluid pumps is essential for optimizing performance and efficiency. The most common types include centrifugal pumps, positive displacement pumps, and diaphragm pumps. According to a recent market analysis by ResearchAndMarkets, the global pump market is expected to reach $82 billion by 2025, driven by the increasing demand for efficient fluid handling solutions across sectors like oil and gas, chemicals, and food processing.

Centrifugal pumps, known for their efficiency and ability to handle large volumes, dominate the market due to their versatility in various applications. They operate by converting rotational kinetic energy into hydrodynamic energy. On the other hand, positive displacement pumps provide a reliable solution for applications requiring consistent flow under varying pressure conditions. A study by Grand View Research indicates that the positive displacement pump segment is projected to grow at a CAGR of 4.6% from 2021 to 2028, reflecting the ongoing need for precision in fluid transfer operations. Understanding these characteristics is vital for industries aiming to enhance production efficiency and reduce operational costs.

Key Factors Driving the Fluid Pump Market: Insights for Industry Professionals

The fluid pump market is poised for significant growth, driven by various factors that industry professionals must consider. One of the primary forces behind this expansion is the increasing demand for efficient handling of fluids across sectors such as manufacturing, construction, and agriculture. The rise in automation and advancements in pump technology, including the development of smart pumps that monitor and optimize performance, are enhancing operational efficiencies and reducing energy consumption. This evolution aligns with global initiatives towards sustainability and cost-effective solutions.

Furthermore, the ongoing investment in infrastructure projects and the need for water management solutions are contributing to the fluid pump market's dynamism. For instance, the global water pump market is expected to see substantial growth as urbanization accelerates and the demand for reliable water supply systems intensifies. Additionally, the infusion pumps sector showcases remarkable potential, with exceptional growth forecasts reflecting the rising healthcare needs. As industry professionals navigate these trends, understanding the specific drivers within their market segments will be essential to capitalize on emerging opportunities and innovate effectively.

Comparative Analysis: Positive Displacement vs. Centrifugal Pumps in Operational Efficiency

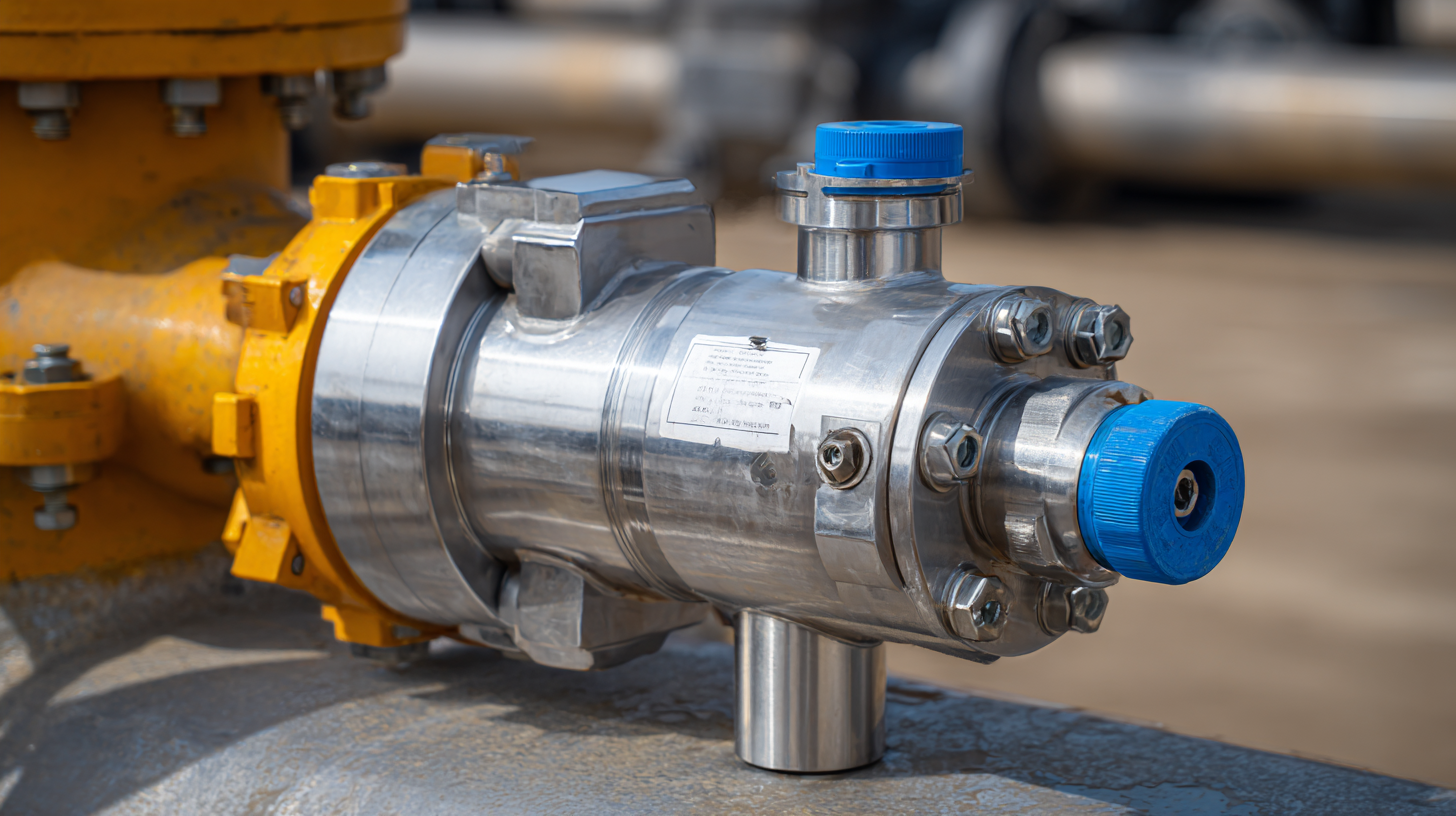

When it comes to fluid pumps in industrial applications, the choice between positive displacement pumps and centrifugal pumps plays a crucial role in operational efficiency. Positive displacement pumps operate by trapping a fixed amount of fluid and forcing it through the discharge pipe, making them ideal for applications requiring precise flow rates and high pressure. They excel in scenarios with highly viscous fluids and provide consistent flow, regardless of system pressure fluctuations.

On the other hand, centrifugal pumps work by converting rotational energy into hydrodynamic energy, making them suitable for applications demanding high flow rates with low viscosity liquids. They are efficient in processes involving water or other low-viscosity fluids, as they can handle significant flow volumes while maintaining a relatively simple design. However, as system pressure increases, the flow rate from centrifugal pumps can diminish, which underscores the importance of selecting the appropriate pump type based on specific operational requirements.

In summary, choosing between positive displacement and centrifugal pumps involves a careful consideration of the application's viscosity, flow rate, and pressure demands. The comparative analysis of these two types of pumps helps industries optimize their fluid handling processes, ensuring maximum operational efficiency tailored to their unique needs.

Emerging Technologies in Fluid Pump Design: Innovations Shaping the Industry

The landscape of fluid pump design is undergoing a significant transformation as emerging technologies introduce innovative solutions, reshaping the industry. Recent advancements in materials engineering have led to the development of pumps that are not only more efficient but also more durable. For instance, the use of advanced composites and lightweight alloys has resulted in pumps that can withstand harsher environments while minimizing maintenance costs. The integration of smart technologies, such as IoT sensors, allows for real-time monitoring and predictive maintenance, enhancing operational efficiency and reducing downtime.

Moreover, the shift towards energy-efficient designs is driving the adoption of optimized hydraulic systems and variable-speed drives. These technologies not only lower energy consumption but also contribute to sustainability goals by reducing the carbon footprint of industrial operations. As manufacturers strive to meet regulatory demands, the incorporation of these innovations into fluid pump design will be crucial in maintaining a competitive edge and ensuring compliance in an ever-evolving marketplace. The future of the fluid pump industry promises exciting developments that will facilitate both operational improvements and environmental responsibility.

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights - Emerging Technologies in Fluid Pump Design: Innovations Shaping the Industry

| Pump Type | Application | Technology Trends | Market Growth (2023-2028) |

|---|---|---|---|

| Centrifugal Pumps | Water supply, chemical processing | Smart sensors, IoT integration | 5.5% CAGR |

| Positive Displacement Pumps | Food and beverage, oil and gas | Variable speed drives, enhanced efficiency | 4.8% CAGR |

| Submersible Pumps | Wastewater treatment, flood control | Automated control systems, energy efficiency | 6.0% CAGR |

| Diaphragm Pumps | Pharmaceutical, chemical transfer | Predictive maintenance, modular designs | 5.0% CAGR |

| Peristaltic Pumps | Biotechnology, food processing | Advanced materials, low-shear pumping | 5.3% CAGR |

Market Trends and Projections: Future Outlook for Fluid Pumps in Various Sectors

The fluid pump market is poised for significant growth, particularly in the low-temperature segment, which is projected to expand from $4.53 billion in 2025 to $75 billion by 2032, with a compound annual growth rate (CAGR) of 7.48%. This rise is primarily driven by advancements in industrial applications seeking efficient and reliable pumping solutions. The fluid cooling systems market is similarly on an upward trajectory, expecting to reach $40.07 billion by 2032, also reflecting a strong CAGR of 8.25%.

As industries continue to evolve, understanding the specific needs related to fluid pumps and cooling systems becomes crucial. Companies should consider investing in advanced pump technologies that not only enhance operational efficiency but also integrate seamlessly with existing systems. Additionally, staying abreast of market trends and projections can provide insights into strategic planning and investment opportunities.

**Tips:** Always assess the durability and efficiency of fluid pumps before making a purchase. Regular maintenance can prolong the lifespan of pump systems and enhance overall performance. Lastly, consider future scalability when selecting a pump to ensure adaptability as your business grows.

Related Posts

-

What is the Functionality Behind Liquid Pumps in Modern Industries

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

Evaluating Cost-Effectiveness: A Comparative Analysis of Pump Rentals vs. Purchasing Equipment

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.