Top 10 Pump Solutions Tips You Need for Efficient Performance

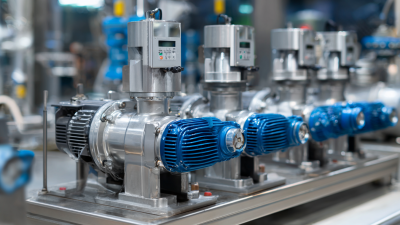

When it comes to ensuring the smooth operation of various industrial processes, pump solutions play a critical role in maintaining efficiency and productivity. Understanding the nuances of pump technologies and their applications can significantly enhance performance while minimizing downtime and operational costs. In this article, we delve into the top ten essential tips that every professional should consider when looking to optimize their pumping systems.

By focusing on key aspects such as maintenance practices, selection criteria, and system monitoring, these insights aim to empower users to make informed decisions about their pump solutions. Whether you are managing a complex industrial setup or a smaller-scale operation, these strategies will help you maximize the effectiveness of your pumps, ultimately leading to improved system reliability and energy savings. Join us as we explore these fundamental tips that can transform your approach to pumping systems and drive greater success in your operational endeavors.

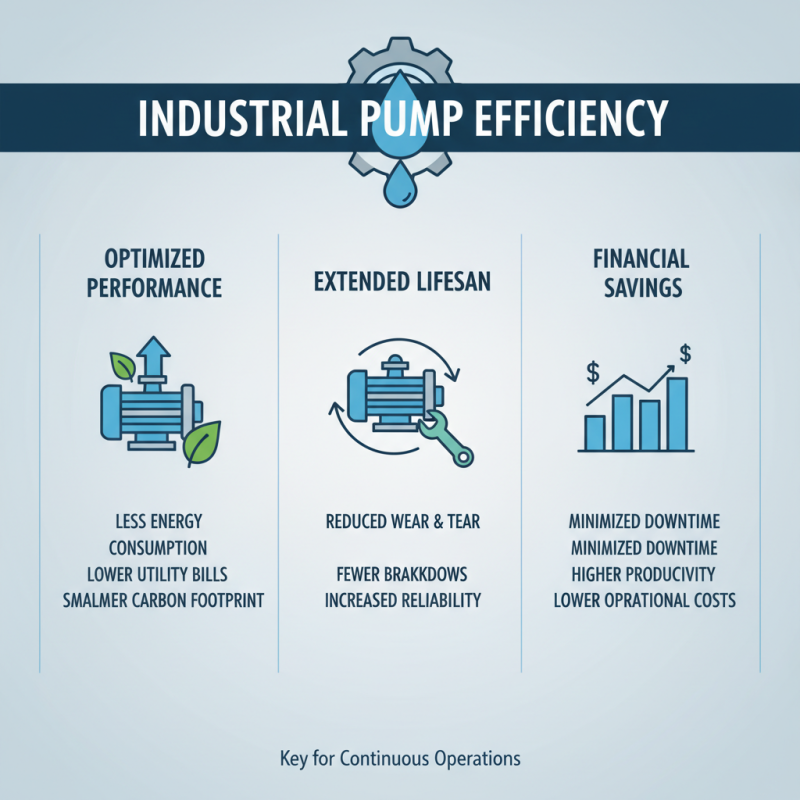

Understanding the Importance of Pump Efficiency in Industrial Applications

In industrial applications, pump efficiency is critical for optimizing performance and reducing operational costs. High-efficiency pumps consume less energy, translating into lower utility bills and a smaller carbon footprint. When pumps operate effectively, they not only enhance the overall productivity of the system but also minimize wear and tear on components, extending their lifespan. This is particularly important in continuous operation environments where downtime can lead to significant financial losses.

Moreover, understanding the factors that influence pump efficiency can lead to better decision-making during the design and maintenance phases. Elements such as pump sizing, fluid characteristics, and system configuration play vital roles in determining how effectively a pump performs. Regular maintenance, monitoring for efficiency loss, and timely repairs are essential practices that ensure optimal function. Emphasizing these aspects not only supports operational excellence but also aligns with sustainability goals, making efficient pump solutions a necessity in modern industrial practices.

Key Factors Influencing Pump Performance in Various Systems

When it comes to optimizing pump performance, several key factors must be carefully considered in various systems. One critical aspect is the selection of the right pump type for the specific application. According to a report by the Hydraulic Institute, approximately 30% of pumping systems are not adequately matched to their intended applications, leading to energy inefficiencies. This mismatch can significantly heighten operational costs and equipment wear. Properly analyzing system requirements and flow characteristics can lead to improved efficiency and longevity of the pump system.

Another factor impacting pump performance is the maintenance regime. Regular maintenance not only helps in identifying potential issues before they escalate but also ensures that the pump operates within its designed efficiency curve. Recommendations from the American Society of Mechanical Engineers suggest that preventive maintenance can enhance pump reliability by as much as 25%. By implementing a rigorous maintenance schedule that includes periodic inspection and fluid analysis, operators can sustain optimal performance levels and avoid costly downtimes.

Tips for effective pump management include monitoring the energy consumption of the pumping system regularly. By utilizing energy monitoring tools, operators can benchmark performance and make informed decisions regarding upgrades and optimizations. Furthermore, educating personnel on system operation and maintenance can empower teams, ensuring that all staff are aware of best practices and potential performance bottlenecks. These steps can lead to substantial performance improvements and greater energy efficiency in pumping systems.

Essential Maintenance Practices for Optimizing Pump Lifespan

Regular maintenance is crucial to ensure the efficient performance and longevity of pump systems. One of the most essential practices is scheduling routine inspections. These inspections should include checking for leaks, vibrations, and unusual noises, which can indicate underlying issues. Identifying potential problems early allows for timely repairs and prevents costly breakdowns, ultimately extending the pump’s service life.

Another key maintenance practice is monitoring the operating conditions, such as temperature, pressure, and flow rates. Keeping these parameters within the manufacturer’s specifications helps avoid wear and tear caused by overloading or inefficient operation. Additionally, regular cleaning of the pump components, including filters and strainers, prevents blockages that can impair performance. Proper lubrication of moving parts is also vital in reducing friction and wear, ensuring smooth operation.

By implementing these essential maintenance practices, operators can optimize pump performance and significantly enhance overall system reliability.

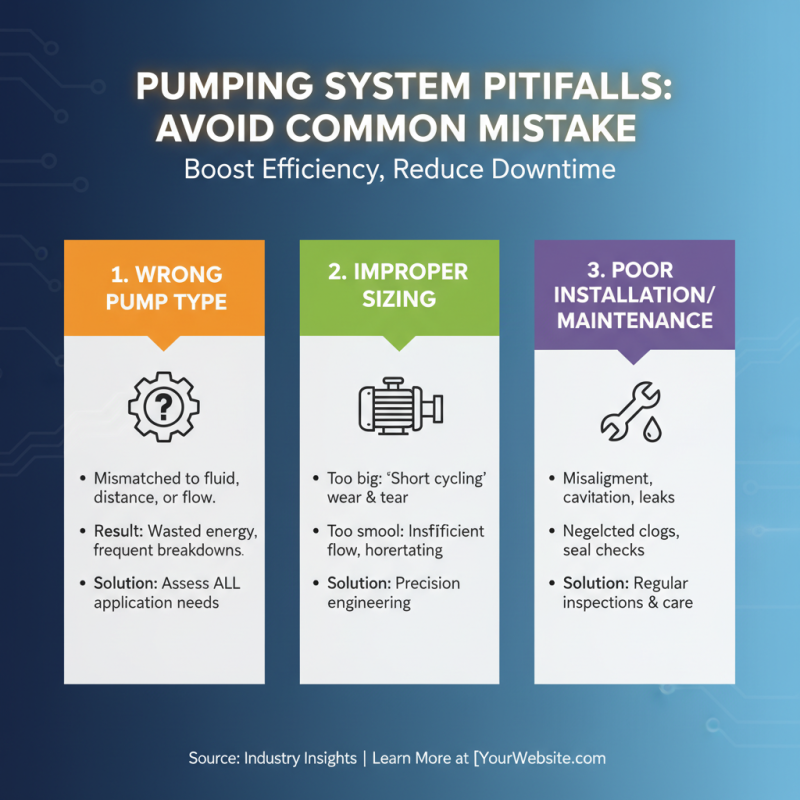

Common Pumping Mistakes and How to Avoid Them

When it comes to pumping systems, even seasoned professionals can fall prey to common mistakes that hinder performance and efficiency. One of the most prevalent errors is selecting the wrong pump type for the specific application. Each pumping system has unique requirements based on the fluid being moved, the distance it needs to travel, and the desired flow rate. Failing to assess these factors properly can lead to increased energy consumption, maintenance issues, and premature pump failure.

Another frequent pitfall is inadequate maintenance. Pump systems require regular inspections and upkeep to ensure they operate smoothly. Neglecting to monitor conditions such as vibration, temperature, and wear can result in costly breakdowns and downtime. Implementing a proactive maintenance schedule and training staff on proper inspection techniques can help identify potential issues before they escalate, ultimately extending the lifespan of the pump and enhancing its efficiency. Making these adjustments can significantly improve the reliability and performance of pumping operations.

Innovative Technologies for Enhancing Pump Efficiency and Reliability

Innovative technologies are revolutionizing the pump industry, significantly enhancing both efficiency and reliability. According to a recent report by the Hydraulic Institute, optimizing pump performance can lead to energy savings of up to 30%, thereby reducing operational costs and environmental impact. Implementing advanced control systems, such as variable frequency drives (VFDs), allows for precise adjustments to flow rates and pressure, improving overall system efficiency. Additionally, smart sensors integrated into pumps provide real-time data monitoring, enabling predictive maintenance, ultimately minimizing downtime and extending the lifespan of the equipment.

To achieve efficient performance, it's crucial to assess and select the right materials for pump components. Utilizing corrosion-resistant materials can enhance reliability while reducing maintenance costs. Furthermore, employing advanced sealing technologies helps prevent leaks and ensures consistent operational performance. As the 2020 Pump System Energy Efficiency Assessment highlighted, addressing these factors can contribute to a 20% increase in pump operational efficiency.

Incorporating these tips not only aligns with industry best practices but also prepares facilities for future challenges in fluid management. The continuous evolution of pump technologies is enabling businesses to achieve greater efficiency, minimize waste, and enhance their overall sustainability. By staying informed about and adopting these innovations, industries can ensure they remain competitive in an increasingly demanding market.

Related Posts

-

Top 10 Benefits of Using Pump Systems for Efficient Fluid Management

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

2025 Top Chemical Injection Pumps: The Ultimate Guide to Choosing the Best Options

-

2025 Top 5 Solar Pump Systems: Revolutionizing Water Solutions for Sustainable Living

-

What Makes a Plunger Pump Different from Other Pump Types

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.