Top Fluid Pumps Types and Their Applications Explained?

Fluid pumps are essential in various industries, from manufacturing to agriculture. According to industry expert Dr. Emily Parker, “Understanding fluid pumps is critical for optimizing processes.” These devices transfer liquids or slurries, making their role critical in many applications.

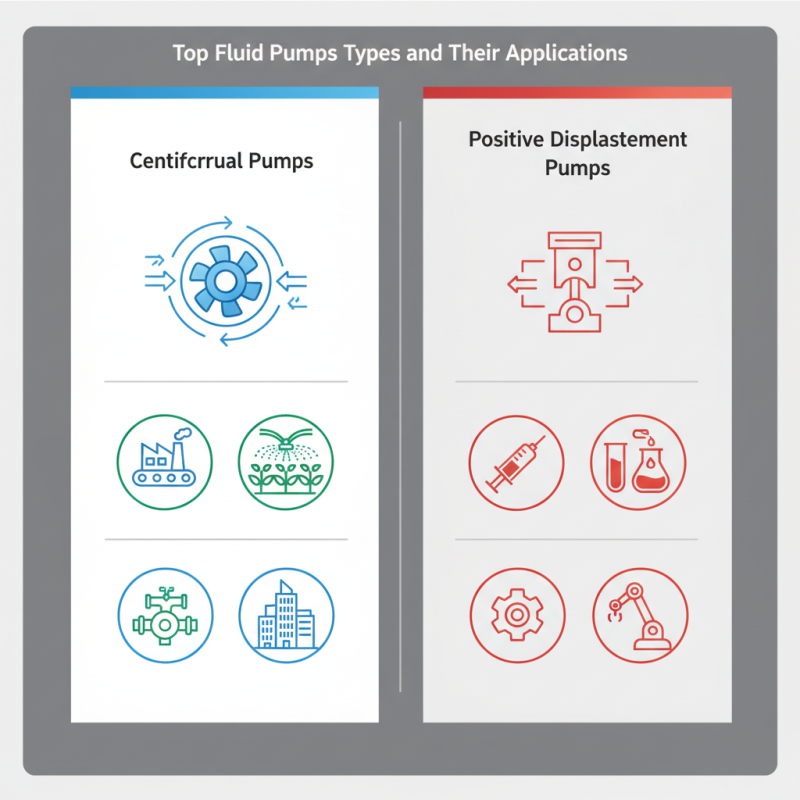

Different types of fluid pumps exist, each designed for specific tasks. Centrifugal pumps can handle high flow rates efficiently, while positive displacement pumps provide precise control. These differences are not merely academic; they impact operational efficiency. A misplaced choice can lead to failures or increased costs.

While many users rely on standard options, unique applications exist that require deeper understanding. Fluid pumps aren’t always straightforward. Exploring their features helps in avoiding common pitfalls. It’s essential to examine industry needs to ensure suitable pump selection. This knowledge can lead to improved performance and reliability in everyday operations.

Overview of Fluid Pumps: Definition and Functionality

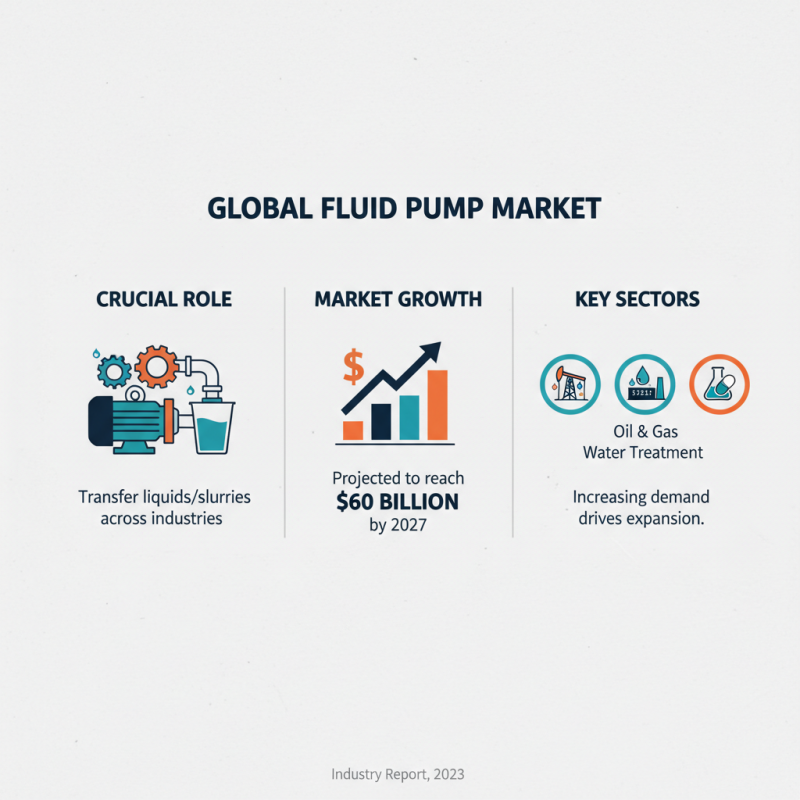

Fluid pumps play a crucial role in various industries. They transfer liquids or slurries from one place to another. According to a recent industry report, the global pump market is projected to reach $60 billion by 2027. This growth indicates increasing demand across sectors like oil and gas, water treatment, and pharmaceuticals.

Understanding the functionality of fluid pumps is essential. They operate on different principles, such as displacement and kinetic energy. Displacement pumps move fluids by trapping a fixed amount and forcing it into the discharge pipe. Conversely, kinetic pumps use impellers to add velocity to a fluid. Each type serves specific applications, but not all designs are perfect. Some can wear out quickly or struggle with viscous fluids, which may cause inefficiencies.

A study highlighted that over 30% of energy consumed in industrial operations is due to fluid movements. This statistic raises concerns about efficiency and sustainability. Many companies are now focused on upgrading pump systems to reduce energy costs and increase reliability. Yet, the challenge remains to balance cost and performance.

Common Types of Fluid Pumps and Their Distinct Features

Fluid pumps play a vital role across various industries. Each type caters to specific needs. Common types include centrifugal and positive displacement pumps. Centrifugal pumps use rotational energy. They are efficient for low-viscosity fluids. These pumps are prevalent in water treatment and chemical processing.

Positive displacement pumps, on the other hand, move fluid by trapping a fixed amount and forcing it through the discharge. They excel in high-viscosity applications found in industries like oil and food processing.

Data from industry reports indicates that the global pump market value was estimated at $77 billion in 2020. It's projected to reach $100 billion by 2028. This growth reflects the increasing demand in manufacturing and energy sectors. However, even with advanced technology, fluid pumps face challenges like wear and tear. Regular maintenance is crucial. Neglecting this can lead to efficiency drops and increased operational costs. Users often overlook this aspect, leading to increased downtime and repairs.

Different pump types also have distinct features. For example, gear pumps provide precise flow control. However, they may struggle with high-pressure situations. Diaphragm pumps offer versatility but can be limited by flow rate. Each option has trade-offs that must be weighed for optimal selection. Careful consideration of these elements ensures better fluid management in operations.

Applications of Fluid Pumps Across Various Industries

Fluid pumps are essential across various industries. Their applications range from water treatment to chemical processing. In the oil and gas sector, pumps move liquids through pipelines. This task is critical to maintain flow and efficiency. According to a report by the Global Market Insights, the pump market in oil and gas was valued at over $15 billion in 2022. However, the technology is not without its challenges. Pipeline leaks can lead to significant environmental damage and economic loss.

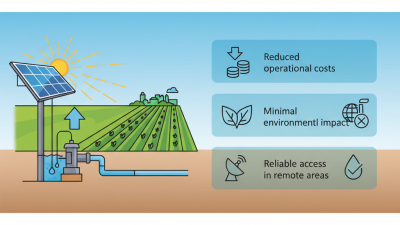

In agriculture, pumps are vital for irrigation systems. They ensure crops receive the necessary water, especially in arid regions. A report by the Food and Agriculture Organization highlights that efficient pumping systems can increase crop yields by up to 20%. Yet, many farmers struggle with outdated equipment. This leads to inefficient water use and increased costs. The need for more sustainable solutions is pressing.

The chemicals industry also relies heavily on fluid pumps for transporting various substances. This sector is projected to grow due to rising demand. However, the handling of hazardous materials poses risks. Safety standards must always be followed to prevent accidents. As industries evolve, the effectiveness and safety of fluid pumps must continuously be re-evaluated.

Top Fluid Pumps Types and Their Applications Explained

| Pump Type | Description | Common Applications | Industry |

|---|---|---|---|

| Centrifugal Pump | Uses rotational energy to move fluids | Water supply, irrigation | Agriculture, Water Treatment |

| Positive Displacement Pump | Moves fluid by trapping a fixed amount and forcing it into the discharge | Pumping viscous fluids, fuel injection | Oil & Gas, Food Industry |

| Diaphragm Pump | Uses a diaphragm to create a vacuum and draw fluids | Chemical transfer, wastewater treatment | Chemical, Waste Management |

| Gear Pump | Uses gear rotation to move fluids | Oil circulation, hydraulic systems | Automotive, Manufacturing |

| Peristaltic Pump | Uses rollers to compress a tube, moving the fluid inside | Pharmaceutical applications, food processing | Pharmaceutical, Food & Beverage |

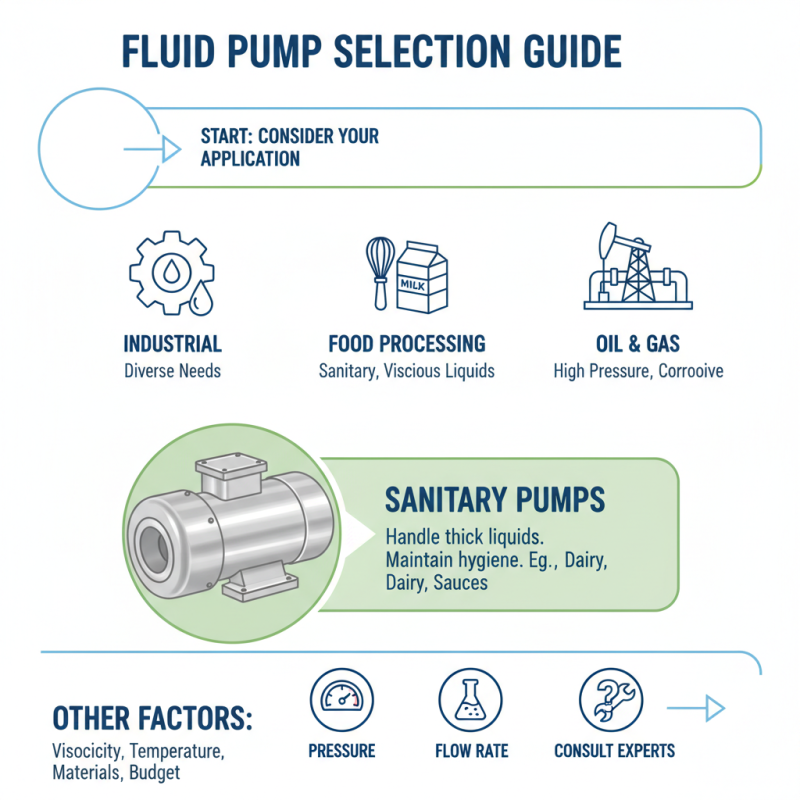

Choosing the Right Fluid Pump for Specific Needs

Choosing the right fluid pump involves several factors. Consider your application first. Different industries require different specifications. For example, food processing typically needs sanitary pumps, which can handle viscous liquids without compromising hygiene.

According to recent industry reports, about 60% of pump selection mistakes stem from miscommunication. Users often fail to clearly define their needs. This can lead to inefficient pumping solutions. A centrifugal pump may be ideal for clean water but not for abrasive sludge. Always analyze the fluid characteristics, such as viscosity and temperature. This is crucial.

Another factor is the pump's energy efficiency. Are you aware that inefficient pumps can consume up to 20% more energy than necessary? This not only raises costs but also increases the carbon footprint. Conduct periodic assessments to ensure you’re using the most suitable pump for your specific application. Reflect on your choices regularly; the wrong pump can lead to operational failures.

Maintenance Tips for Optimal Performance of Fluid Pumps

Fluid pumps play a crucial role in various industries. To ensure they function at their best, regular maintenance is essential. Start by checking for any leaks. Even a small leak can lead to significant performance issues. Inspect hoses and fittings thoroughly. Replace any worn or damaged parts promptly.

Next, monitor the pump’s vibration levels. Excessive vibration may indicate misalignment or internal wear. Address these issues to prevent further damage. Regularly change the lubricants used in the pump. Old or contaminated lubricants can reduce efficiency and cause increased wear.

Finally, keep an eye on the pump’s operating temperature. Overheating can result in permanent damage. Occasionally, operating conditions may change unexpectedly. It's vital to reassess these conditions regularly. Ignoring maintenance can lead to costly downtime. Consistent attention to these details promotes optimal performance and longevity.

Related Posts

-

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

10 Essential Tips for Choosing the Best Fluid Pumps for Your Project

-

Why a Solar Pump System is the Best Choice for Your Water Needs

-

What is a Pneumatic Pump? How It Works and Its Applications Explained

-

Top 10 Pressure Pumps for Ultimate Efficiency in 2023

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.