Top 5 Electric Diaphragm Pumps for Efficient Fluid Transfer?

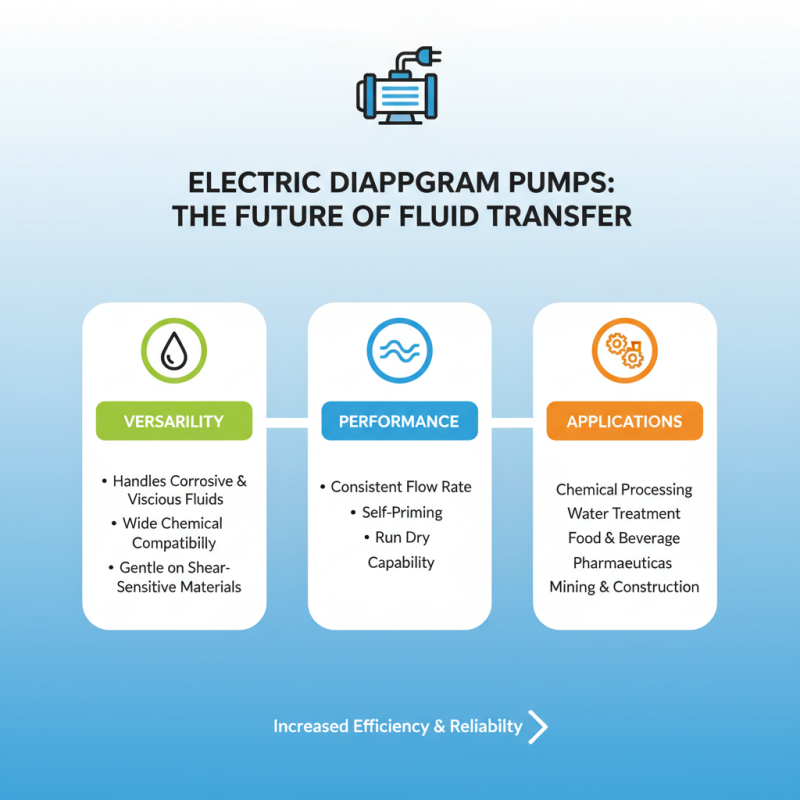

Electric diaphragm pumps are essential tools for efficient fluid transfer in various industries. These pumps offer reliable performance and versatility. They suit numerous applications, including agriculture, chemical processing, and food production. Choosing the right electric diaphragm pump can significantly impact your operations.

When evaluating options, consider factors such as flow rate, pressure capacity, and materials. Each detail matters in achieving optimal performance. It’s crucial to assess your specific needs to find the best fit. Keep in mind that not every pump is perfect for every job. Some models may underperform in particular environments, leading to frustrations.

Investing in the right electric diaphragm pump can save time and resources. However, understanding the limitations of each option is vital. The top five models will be highlighted, showcasing their strengths and potential weaknesses. Each has unique features that may align with your requirements. Let's explore these options for efficient fluid transfer.

Understanding Electric Diaphragm Pumps and Their Applications

Electric diaphragm pumps are versatile. They are widely used for fluid transfer applications. Their design features a diaphragm that creates suction. This allows for accurate handling of various liquids. Common uses include chemical processing, wastewater management, and food production.

Tips: Always check compatibility with the fluid. Some materials may degrade faster than others. Additionally, consider the pump's flow rate. It should match your application's needs.

These pumps also provide safety advantages. They can operate in hazardous environments. However, not all pumps are suitable for every application. It's crucial to assess your specific needs. Testing under real conditions can reveal performance issues.

Tips: Invest time in selecting the right pump. Ask for advice if unsure. Regular maintenance is essential for long-term efficiency. Small issues, if left unchecked, can lead to bigger problems.

Top 5 Electric Diaphragm Pumps for Efficient Fluid Transfer

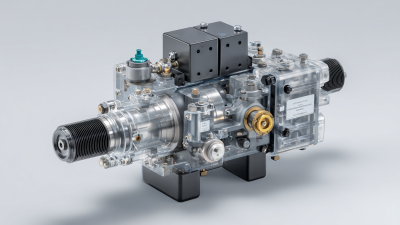

Key Features to Consider When Choosing an Electric Diaphragm Pump

When selecting an electric diaphragm pump, several key features should be in your toolkit.

Flow rate is crucial. You want a pump that can transfer the desired volume efficiently.

A higher flow rate means less time spent on moving fluids. However, balancing flow with the right pressure is also important.

Ensure the pump can handle the required pressure for your applications.

Durability is another essential feature. Look for materials that resist corrosion.

Pumps often face challenging environments. A well-constructed pump can last longer and require less maintenance.

Additionally, consider the size and weight of the pump. A compact design can be easier to install and transport.

Noise levels and energy efficiency may often be overlooked.

Some pumps are surprisingly loud, which can be disruptive.

Opting for a quieter model can improve working conditions. Lastly,

energy consumption affects operating costs.

More efficient pumps can save you money in the long run. So, make an informed decision based on all these considerations.

Each choice impacts functionality and satisfaction.

Top 5 Electric Diaphragm Pumps for Efficient Fluid Transfer

Electric diaphragm pumps are gaining popularity for fluid transfer across various industries. Reports show these pumps can handle a wide range of fluids, including corrosive and viscous materials. Their ability to provide a consistent flow rate is crucial in many applications.

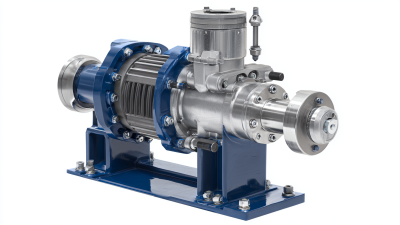

One notable advantage is their efficiency. According to a recent industry report, electric diaphragm pumps can achieve up to 90% energy efficiency. This is significantly better than traditional pumps. However, users must consider factors like noise levels and maintenance needs. While some models run quietly, others can be quite loud. Choosing the right model often requires trade-offs.

Fluid contamination is another point of concern. While diaphragm pumps can prevent backflow and contamination, improper installation may lead to leaks. Regular inspections are essential. Some users overlook this, which can result in costly repairs. It's important to reflect on the balance between performance and maintenance.

Comparative Analysis of the Selected Electric Diaphragm Pumps

When selecting electric diaphragm pumps, efficiency is key. These pumps are renowned for their ability to transfer fluids with minimal energy consumption. A recent industry report highlighted that electric diaphragm pumps can reduce energy costs by up to 30% compared to traditional pumps. This makes them ideal for various applications, including chemical processing and water treatment.

Comparing different models reveals that flow rates and pressure handling vary significantly. Some pumps can achieve flow rates of over 20 gallons per minute (GPM), while others might range from 5 to 15 GPM. It’s essential to match the pump capacity to your specific needs. Misjudging flow rates can lead to system inefficiencies, wasting valuable resources.

Tips: Always review pump specifications before making a decision. Consider the types of fluids being transferred. Some pumps are better suited for corrosive materials, while others handle viscous liquids more effectively. Maintenance is another factor; pumps require regular checks to ensure optimal performance. Neglecting this can reduce their lifespan and efficiency. Keep an eye on wear and tear, as this is often overlooked in many setups. Regular maintenance is often a weak link in operational efficiency.

Maintenance Tips for Prolonging the Life of Diaphragm Pumps

Maintaining diaphragm pumps is crucial for optimal performance. Regular maintenance not only prolongs the lifespan of the pumps but also ensures safe operations. A well-maintained pump operates more efficiently, saving both energy and time.

One effective tip is to check the air supply pressures regularly. If they fluctuate, your pump can suffer. This could lead to uneven fluid transfer. Ensure hoses and fittings are tight to prevent leaks. Even a small leak can disrupt the entire system.

Cleaning is another vital aspect of maintenance. Accumulated debris can damage pump components over time. Use appropriate cleaning solutions to remove buildup regularly. Pay close attention to check valves and diaphragm surfaces. Monitoring these parts helps avoid costly repairs down the line.

Remember, keeping a maintenance schedule is equally important. Document your findings each time you inspect the pump. This tracking can reveal patterns that may need addressing. Often, minor adjustments can prevent major issues in the future. A proactive approach to maintenance will undoubtedly lead to better performance.

Related Posts

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

How to Effectively Pump Water for Your Home Garden?

-

How to Optimize Your Injection Pumps for Maximum Efficiency and Performance

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

Understanding the Benefits of Plunger Pumps in Industrial Applications

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.