2025 Top Chemical Injection Pumps: The Ultimate Guide to Choosing the Best Options

In the ever-evolving landscape of industrial processes, chemical injection pumps play a crucial role in ensuring the efficient and precise delivery of chemicals across various applications, including water treatment, oil and gas production, and chemical manufacturing. According to a recent report by MarketsandMarkets, the chemical injection pump market is projected to grow from USD 2.46 billion in 2020 to USD 4.15 billion by 2025, indicating a compound annual growth rate (CAGR) of 10.8%. This expansion is driven by the increasing demand for advanced pumping technologies that can enhance operational efficiency and meet stringent regulatory standards.

Choosing the right chemical injection pump is paramount for optimizing chemical dosing and improving overall system performance. With a myriad of options available in the market, including diaphragm, peristaltic, and gear pumps, the selection process can often be daunting. Factors such as flow rate, pressure requirements, and chemical compatibility must be carefully considered to ensure that the chosen pump aligns with operational goals and environmental regulations. In this ultimate guide, we will delve into the top chemical injection pumps of 2025, providing insights and recommendations to assist you in making an informed decision that caters to your specific operational needs.

The Importance of Chemical Injection Pumps in Industrial Applications

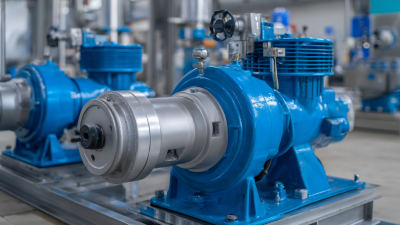

Chemical injection pumps play a vital role in various industrial applications, serving as a critical component in processes such as water treatment, oil and gas production, and chemical manufacturing. These pumps are designed to deliver precise amounts of chemicals into a system, ensuring optimal performance and safety. The accurate dosing provided by chemical injection pumps helps maintain the desired chemical concentrations, which is essential for processes like corrosion control, pH adjustment, and disinfection.

In industrial settings, the reliability and efficiency of chemical injection pumps directly impact production quality and operational costs. Selecting the appropriate pump is crucial, as it can enhance system performance and reduce waste. Factors such as chemical compatibility, flow rate requirements, and operational pressure must be carefully considered when choosing a pump. The right chemical injection pump not only improves the effectiveness of chemical treatment processes but also ensures compliance with environmental regulations, thereby minimizing the potential for spills and leaks that can harm both the environment and public health.

Key Features to Look for in Top Chemical Injection Pumps

When selecting the best chemical injection pumps in 2025, one must consider several key features that can significantly enhance performance and reliability. Firstly, the pump's material construction is critical; it should be compatible with the chemicals being injected to prevent corrosion and ensure longevity. Common materials include polypropylene and stainless steel, which are known for their resistance to harsh chemicals. Additionally, the pump should have robust sealing mechanisms to avoid leaks, which can lead to environmental hazards.

When selecting the best chemical injection pumps in 2025, one must consider several key features that can significantly enhance performance and reliability. Firstly, the pump's material construction is critical; it should be compatible with the chemicals being injected to prevent corrosion and ensure longevity. Common materials include polypropylene and stainless steel, which are known for their resistance to harsh chemicals. Additionally, the pump should have robust sealing mechanisms to avoid leaks, which can lead to environmental hazards.

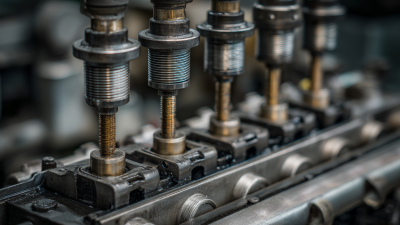

Another crucial feature is the pump's flow rate and pressure capabilities. Understanding the required flow rates for specific applications helps in choosing a pump that can efficiently handle the required workload. Furthermore, adjustable flow rates can provide flexibility for varying operational needs. Advanced technology in chemical injection pumps, such as digital controls and monitoring systems, also enhances accuracy and ease of use, allowing for better management of chemical dosing. These features collectively ensure optimal performance and safety in chemical handling.

Comparative Analysis of the Top 2025 Chemical Injection Pump Brands

The chemical injection pump market is rapidly evolving, driven by advancements in technology and increasing demand across various industries. According to a recent analysis, the metering pumps market is projected to reach approximately USD 7.5 billion by 2025. This growth is fueled by an emphasis on precise chemical dosing, which is critical for maintaining optimal operational efficiency in sectors such as oil and gas, water treatment, and pharmaceuticals.

A comparative analysis of leading chemical injection pump brands reveals significant differences in their offerings. Factors such as design, material compatibility, flow rate accuracy, and automation capabilities play a pivotal role in selecting the right pump for specific applications. Moreover, expert interviews indicate that ease of maintenance and customer support are vital considerations for end-users. As companies strive to enhance productivity while minimizing environmental impact, the right choice of a chemical injection pump will be crucial in achieving these goals.

2025 Top Chemical Injection Pumps Comparative Analysis

This chart illustrates the performance metrics of the leading chemical injection pumps in 2025 across several key dimensions including Flow Rate (L/hr), Pressure Rating (bar), and Efficiency (%).

Cost vs. Performance: Finding the Best Value in Chemical Injection Pumps

When selecting the ideal chemical injection pump in 2025, understanding the balance between cost and performance is crucial. A higher price tag does not always guarantee superior efficiency or longevity; therefore, careful evaluation of different models is essential. Look for pumps that provide reliable performance at a competitive price point, ensuring that you achieve the maximum return on your investment.

Tips: Consider the total cost of ownership, which includes installation, maintenance, and operation costs. Often, a more economical pump may incur higher maintenance expenses, negating initial savings. Researching user reviews and service histories can also offer insights into long-term reliability.

Additionally, assess your specific needs, such as the type of chemicals being injected, flow rate requirements, and environmental conditions. Some pumps are tailored for specific applications, which can enhance performance and reduce downtime.

Tips: Implementing a life cycle assessment can help you make informed decisions. Evaluating how a pump performs over time under real conditions will help identify the best value choices for chemical injection systems. Don't overlook warranty and service options, as these can be indicators of a manufacturer's confidence in their product.

User Testimonials: Real-World Experiences with the Best Chemical Injection Pumps

When selecting the best chemical injection pumps for your needs, user testimonials can provide invaluable insights into real-world experiences. Many users highlight the importance of reliability and consistent performance in their daily operations. For instance, operators in the water treatment sector often rave about pumps that maintain accurate dosing levels, which directly correlates to process efficiency and safety. One user noted, "Our chemical injection pump has not only reduced downtime but also improved our overall output by ensuring precise chemical levels."

Tips for choosing the right chemical injection pump often include considering the application and environment in which the pump will operate. Different pumps cater to various chemicals and pressure requirements, so ensure the pump you select can handle the specific characteristics of the chemicals you are working with. Additionally, check for features like ease of maintenance and compatibility with existing systems, as users frequently share that a user-friendly design significantly enhances operational efficiency.

Moreover, many testimonials stress the importance of customer support from manufacturers. A helpful support team can make a significant difference, especially when troubleshooting potential issues. As one customer shared, "Having prompt assistance from our pump provider has saved us time and prevented costly repairs." Investing in a manufacturer known for excellent service can lead to a smoother experience and higher satisfaction with your chemical injection pump choice.

Related Posts

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

Understanding the Role of Chemical Pumps in Enhancing Water Treatment Efficiency

-

Maximizing Efficiency: The Role of Chemical Injection Pumps in Reducing Operational Costs by 20% in the Oil Industry

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

Innovative Liquid Pumps: Transforming Industrial Efficiency and Performance

-

How to Optimize Your Injection Pumps for Maximum Efficiency and Performance

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.