Top Tips for Choosing the Right Pneumatic Pump for Your Needs?

In today's industrial landscape, selecting the proper pneumatic pump can significantly affect operational efficiency. According to a report by Freedonia Group, the global demand for pneumatic pumps is expected to reach $5.2 billion by 2024. This highlights the growing reliance on these tools across various sectors, from manufacturing to construction.

Pneumatic pumps are known for their efficiency and versatility. They can handle a range of materials, from water to viscous fluids. However, choosing the right model involves understanding specific requirements. Factors such as pressure capacity, flow rate, and material compatibility are crucial. Yet, many users overlook these details, leading to inefficiencies and increased costs.

Understanding the unique specifications of a pneumatic pump is essential. Not every model suits every application. As highlighted in an industry analysis, 30% of companies report issues due to poor pump selection. It is vital to reflect on these choices and consider the long-term implications on productivity and maintenance. A thoughtful approach will lead to better performance and reliability in the long run.

Key Considerations for Selecting a Pneumatic Pump Type

Choosing the right pneumatic pump involves several key considerations. Start by evaluating the pump's application. What material will it handle? Different fluids require specific pump designs. For example, some pumps work best with viscous fluids, while others excel with gases. Knowing your medium helps narrow down options.

Next, think about pressure requirements. Pneumatic pumps can operate at various pressure levels. Higher pressure can mean better performance in certain applications. But it’s essential to ensure that the pump can sustain this pressure reliably. Sometimes, selecting a pump that’s slightly over-engineered can be wise, but it could lead to unnecessary costs. Reflect on your actual needs.

The size and portability of the pump also matter. Will it need to fit into a compact space? Or will it be moving frequently? A portable design may have limitations in capacity or output. Balancing power and size is crucial. If your operation evolves, consider if the pump allows for future upgrades or adjustments. This flexibility can save time and money.

Top Tips for Choosing the Right Pneumatic Pump

Understanding the Specific Applications for Pneumatic Pumps

When selecting a pneumatic pump, understanding its specific applications is crucial. Pneumatic pumps are popular in various industries, including construction, automotive, and manufacturing. For instance, in construction, they are used to power tools and equipment efficiently. In automotive applications, these pumps can deliver high-pressure air for tire inflation or paint spraying.

Different pneumatic pumps serve specific functions. Some are ideal for transferring fluids, while others excel in vacuum applications. Consider the materials involved in your application. For example, abrasive materials may require a more robust pump design. Users often overlook compatibility, leading to maintenance issues. A pump unsuitable for specific materials can cause rapid wear or malfunction.

It's also essential to think about the environment where the pump will operate. Humidity, temperature, and space constraints play a significant role in performance. Sometimes, the chosen pump may not fit perfectly in the designated area. This challenge often leads to operational inefficiencies. Users must reflect on their choices, ensuring that the pneumatic pump meets all criteria for their unique needs.

Evaluating Flow Rate and Pressure Requirements for Your System

When selecting a pneumatic pump, evaluating flow rate and pressure requirements is crucial. Flow rate is typically measured in liters per minute (LPM) or cubic feet per minute (CFM). For many applications, a flow rate of 5 to 20 LPM suffices. However, high-demand operations may require rates exceeding 100 LPM. Accurate assessment of your system's needs will ensure optimal performance and prevent operational headaches.

Pressure is equally important. Most pneumatic systems operate between 80 to 120 psi. However, applications like material transport often require pressures above 150 psi. Knowing your system's baseline pressure needs prevents underperformance or equipment failure. Industry reports highlight that improper pressure settings can lead to a 30% decrease in efficiency.

Tip: Always calculate the demand before purchasing. Consider the maximum flow rate and operating pressure. Examine your system layout; longer distances might need higher pressure. It's a misconception that maximizing flow is always best. A balanced approach often yields better results.

Another tip: double-check compatibility. Different materials interact uniquely under pressure. Using incompatible materials could lead to leaks or failures. Keep in mind that even small changes in pressure can impact the entire system. Evaluate existing components to avoid surprises during installation.

Assessing Material Compatibility and Construction Standards

When selecting a pneumatic pump, assessing material compatibility is crucial. Different materials handle different fluids. For example, certain plastics are not suitable for corrosive substances. Steel may be preferable for aggressive chemicals. Understanding the specific requirements of your application is essential. A mismatch can lead to equipment failure.

Construction standards also play a significant role. Not all pumps are built to the same specifications. Some may have superior durability. Review the pressure ratings and temperature tolerances. Think about long-term use. Ask yourself, “Will it withstand my working conditions?” Even small details like seal quality matter. The wrong choice can result in unexpected downtime.

Remember, not every pump will meet all your needs perfectly. Take time to evaluate options. There might be trade-offs in cost and performance. Seeking advice from experts can help clarify confusion. Ultimately, your choice should reflect careful thought and practical requirements. Make sure you have considered all factors before making a decision.

Top Tips for Choosing the Right Pneumatic Pump for Your Needs

| Pump Type | Material Compatibility | Max Pressure (psi) | Construction Standards | Applications |

|---|---|---|---|---|

| Diaphragm Pump | Water, Chemicals | 100 | ISO 9001 | Agriculture, Industrial |

| Vane Pump | Air, Oil | 150 | CE Marking | Automotive, Manufacturing |

| Piston Pump | Hydraulic Fluids, Water | 200 | API Certification | Construction, Oil & Gas |

| Gear Pump | Viscous Liquids | 250 | ASME Standards | Chemical Processing, Food Industry |

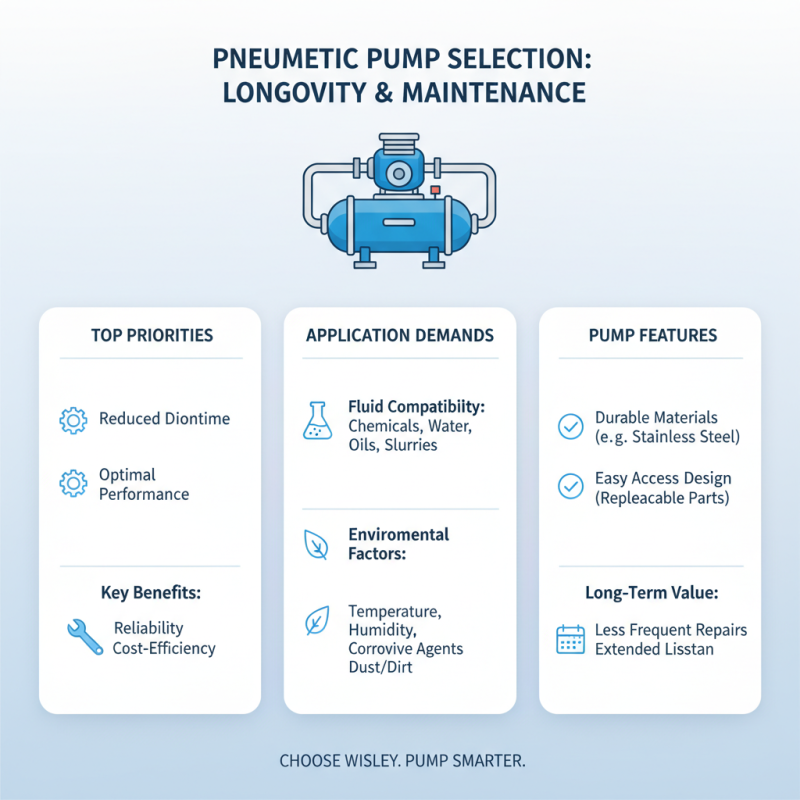

Maintenance and Longevity: Choosing the Right Pneumatic Pump Model

When selecting a pneumatic pump, maintenance and longevity should be top priorities. A well-chosen model reduces downtime and ensures optimal performance. It’s essential to understand the specific demands of your application. For instance, consider fluid compatibility and environmental factors.

Before purchasing, evaluate the pump’s construction materials. Corrosion-resistant options can enhance durability. Regular maintenance is critical. This includes checking seals and lubricating moving parts. Cleaning the pump regularly can prevent buildup that leads to wear.

Tips for selecting the right model include consulting user manuals and online resources. Do your research on operating costs. Investing in quality upfront can pay off in the long run. Also, don’t overlook warranty details. A good warranty is often a sign of a reliable product. Each of these considerations contributes to choosing a pump that will last.

Related Posts

-

How to Choose the Best Diaphragm Pump for Your Needs: A Comprehensive Guide

-

2025 How to Choose the Best Pressure Pumps for Your Needs

-

2026 Top Plunger Pump Innovations and Trends to Watch Out For?

-

Exploring Check Valve Innovations at the 2025 China Import and Export Fair

-

2025 Top Chemical Injection Pumps: The Ultimate Guide to Choosing the Best Options

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.