Unlocking the Secrets of Liquid Pumps and Their Impact on Modern Technology

The advent of advanced liquid pumps has transformed numerous sectors, driving innovation and enhancing efficiency in modern technology. According to recent reports from the Global Liquid Pumps Market Research, the liquid pump industry is projected to grow significantly, reaching an estimated value of $59.4 billion by 2027, expanding at a compound annual growth rate (CAGR) of 4.3%. This growth is fueled by the increasing demand in various applications such as water supply, wastewater treatment, and chemical processes.

Liquid pumps, characterized by their versatility and reliability, are critical components in industries ranging from manufacturing to healthcare. They enable the effective transport and handling of liquids, thereby facilitating operations that would otherwise be impractical. For instance, the petroleum industry heavily relies on liquid pumps for refining processes and distribution, while the pharmaceutical sector utilizes them for precise formulations. As the push for sustainable technologies intensifies, innovations in liquid pump designs are also contributing to energy efficiency and reduced environmental impact.

In this article, we will delve deeper into the secrets behind liquid pumps, exploring their technological advancements and the profound impact they have on modern technology. By understanding these dynamics, we can better appreciate the role that liquid pumps play in shaping the future of industrial applications and enhancing our daily lives.

Understanding the Basic Principles Behind Liquid Pumps

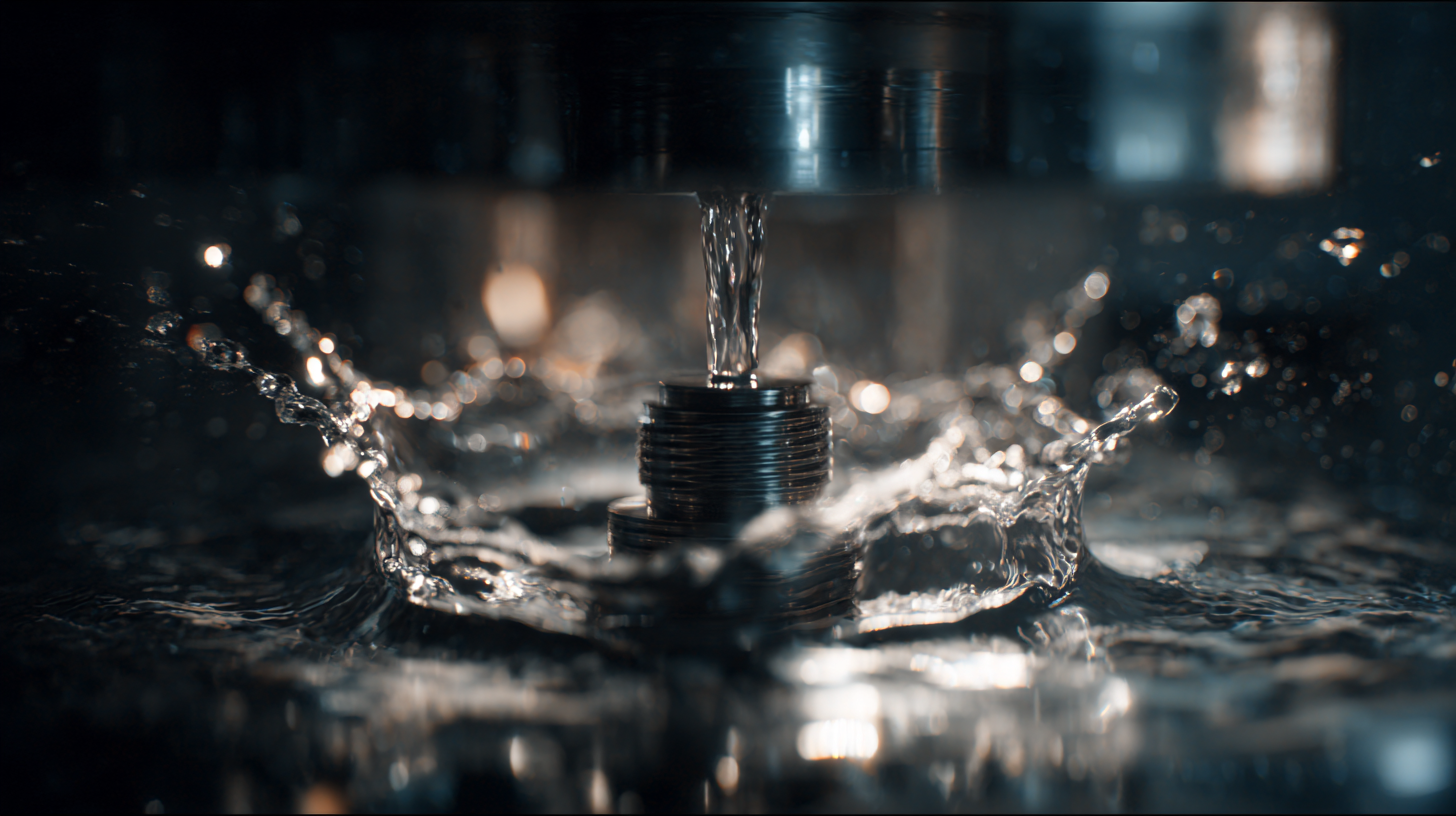

Liquid pumps play a crucial role in various sectors, including manufacturing, healthcare, and environmental management. At their core, these devices function by converting mechanical energy into hydraulic energy, thus facilitating the movement of liquids through a system. This is achieved through different mechanisms such as centrifugal force in centrifugal pumps or positive displacement in diaphragm pumps. According to a recent market analysis by Research and Markets, the global liquid pump market is projected to grow at a CAGR of 4.5% from 2023 to 2030, driven by advances in technology and rising demand across industries.

Understanding the basic principles behind these pumps is vital for optimizing their application in modern technology. For instance, centrifugal pumps are highly efficient for transporting large volumes of liquid at low pressure, making them ideal for applications in municipal water supply and chemical processing. In contrast, positive displacement pumps are better suited for high-viscosity liquids or applications requiring precise flow rates. The International Pump Manufacturers Association states that proper selection and maintenance of pumps can improve energy efficiency by up to 30%, highlighting the importance of understanding their operational principles to enhance performance and sustainability.

The Evolution of Liquid Pump Technology in Industrial Applications

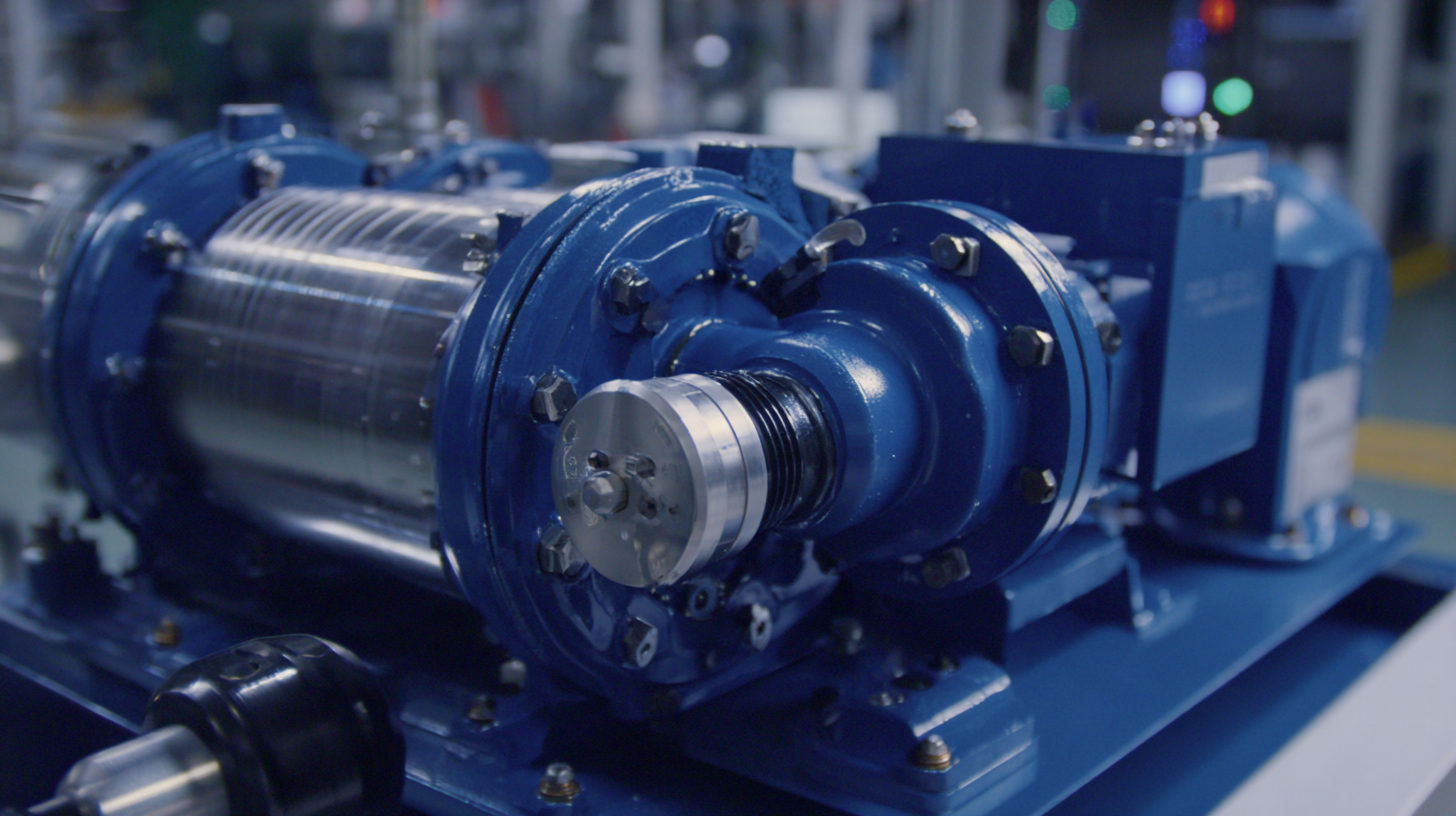

The evolution of liquid pump technology has been pivotal in numerous industrial applications, significantly enhancing efficiency and productivity. According to a report by MarketsandMarkets, the global pump market is projected to reach USD 100 billion by 2026, driven by increasing demands in sectors such as water management, chemicals, and oil and gas. Innovations in pump design, such as variable frequency drives (VFDs) and advanced materials, have contributed to better performance and energy efficiency, reducing operational costs across industries.

In addition, the development of smart pump technologies, equipped with IoT capabilities, has transformed the landscape of liquid handling systems. A report from Deloitte Insights highlights that such technologies can lead to up to a 40% improvement in energy efficiency. By utilizing real-time data monitoring and predictive maintenance, industries are now able to minimize downtime and extend the lifecycle of pumping equipment. This technological evolution not only supports sustainability goals but also enhances the overall reliability of liquid distribution systems in various industrial scenarios.

Unlocking the Secrets of Liquid Pumps in Industrial Applications

Exploring the Role of Liquid Pumps in Renewable Energy Systems

Liquid pumps play a crucial role in the advancement of renewable energy systems, significantly enhancing their efficiency and effectiveness. As the world increasingly shifts towards sustainable energy sources, the integration of liquid pumps in technologies such as geothermal systems and hydropower becomes essential. For instance, geothermal heat pumps leverage the constant temperature of the earth to provide heating and cooling solutions that are both cost-effective and environmentally friendly. These systems can reduce energy consumption by up to 50% compared to conventional systems, making them a compelling choice for residential and commercial applications.

When exploring the impact of liquid pumps in renewable energy, it's important to consider their application in district heating systems. Centralized heating solutions utilize a network of pumps to distribute thermal energy to various locations, optimizing energy use and reducing greenhouse gas emissions. Reports indicate that district heating can decrease CO2 emissions by as much as 30% compared to individual heating systems, underscoring the critical role pumps play in achieving climate targets.

Tips: When considering a geothermal or district heating system, evaluate the local energy sources and potential government incentives. Staying informed about advancements in pump technology, such as the use of nanofluids, can enhance system performance and operational costs. Regular maintenance of pumping systems is essential to ensure long-term efficiency and reliability.

The Impact of Liquid Pumps on Healthcare and Medical Devices

Liquid pumps play a crucial role in the healthcare sector, particularly in medical devices where precision and reliability are essential. According to a report by Grand View Research, the global medical pumps market is expected to reach $43.4 billion by 2025, driven largely by increasing demand for advanced healthcare solutions. Various types of liquid pumps, including peristaltic and syringe pumps, facilitate drug delivery systems, ensuring that medications are administered accurately and consistently. These technologies have revolutionized patient care by allowing for continuous and controlled infusion rates, which is vital in critical situations.

In addition to drug delivery, liquid pumps also contribute significantly to diagnostic equipment. The ability to manage fluid dynamics effectively is essential for devices such as blood analyzers and dialysis machines, which rely on precise fluid handling for accurate results. Furthermore, a study by MarketsandMarkets forecasts that the global market for healthcare fluid management systems will reach $22.6 billion by 2026, indicating a growing reliance on efficient liquid handling solutions in medical applications. As technology advances, the integration of smart pumping systems with IoT capabilities will further enhance the quality of healthcare, providing real-time monitoring and automation in fluid management processes.

Future Innovations: How Liquid Pumps Will Shape Smart Technologies

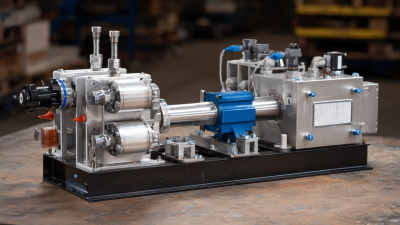

The household water pump market is on a significant growth trajectory, projected to reach a value of $18.58 billion in 2024 and expand to $26.92 billion by 2032, with an impressive compound annual growth rate of 4.8%. This increase is indicative of the broader trend where liquid pumps are becoming integral to modern technology, particularly in smart technologies. As automation and smart systems evolve, the demand for efficient liquid management solutions, such as those provided by advanced liquid pumps, is on the rise.

Innovations in liquid pump technology are paving the way for advancements across various sectors. For instance, the introduction of intelligent work face systems in mining illustrates how autonomous operations leverage sophisticated pump systems for efficient resource extraction. Similarly, at the forefront of cleaning technology, the development of heat washing machines demonstrates the merging of liquid pump capabilities with smart technology. Such innovations not only enhance performance but also contribute to sustainability goals, reinforcing the role of liquid pumps as a backbone of future technological solutions.

Related Posts

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

Innovative Liquid Pumps: Transforming Industrial Efficiency and Performance

-

Maximizing Efficiency in Industrial Processes with Advanced Electric Chemical Injection Pumps

-

Maximizing Efficiency: The Role of Chemical Injection Pumps in Reducing Operational Costs by 20% in the Oil Industry

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.