Understanding the Role of Chemical Pumps in Modern Industrial Applications

The significance of chemical pumps in modern industrial applications cannot be overstated, as they play a critical role in the efficient and safe handling of various fluids across multiple sectors. According to a recent market report by Grand View Research, the global chemical pumps market is projected to reach $9.6 billion by 2027, growing at a CAGR of 4.6% from 2020. This growth is driven by the increasing demand for chemical processing, water and wastewater treatment, and the rising need for energy-efficient pumping solutions.

Chemical pumps are essential for managing the intricate processes involved in transporting corrosive, viscous, or hazardous materials, thus ensuring operational reliability and safety. As industries continue to evolve, the integration of advanced technologies, such as digital monitoring and automation, is enhancing the performance and sustainability of chemical pumps, making them indispensable components in the modern industrial landscape.

Key Functions of Chemical Pumps in Industrial Settings

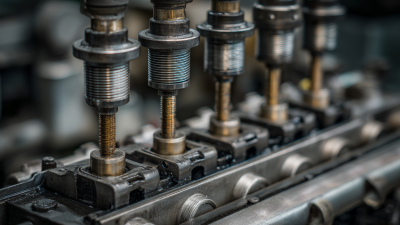

Chemical pumps play a crucial role in various industrial settings, facilitating the efficient transfer and management of fluids, particularly corrosive or hazardous chemicals. One key function of these pumps is to maintain precise flow rates, ensuring that the necessary amounts of chemicals are delivered to processes like mixing, reactions, or other operational setups. Their ability to operate under specific pressures and temperatures makes them indispensable in industries such as pharmaceuticals, chemical manufacturing, and wastewater treatment.

Another critical function of chemical pumps is to minimize the risk of leaks and spills, which can pose safety hazards and environmental threats. Many modern chemical pumps are designed with advanced sealing technologies and materials that resist chemical degradation, thereby enhancing reliability and durability. Additionally, these pumps often feature automation capabilities, allowing for real-time monitoring and control, which further boosts operational efficiency and safety. In summary, chemical pumps are integral to maintaining productivity and safety in industrial applications by delivering precise chemical handling and minimizing risk factors.

Understanding the Role of Chemical Pumps in Modern Industrial Applications

This bar chart illustrates the key functions of chemical pumps in various industrial applications. The data reflects the percentage of usage in different sectors.

Types of Chemical Pumps and Their Unique Applications

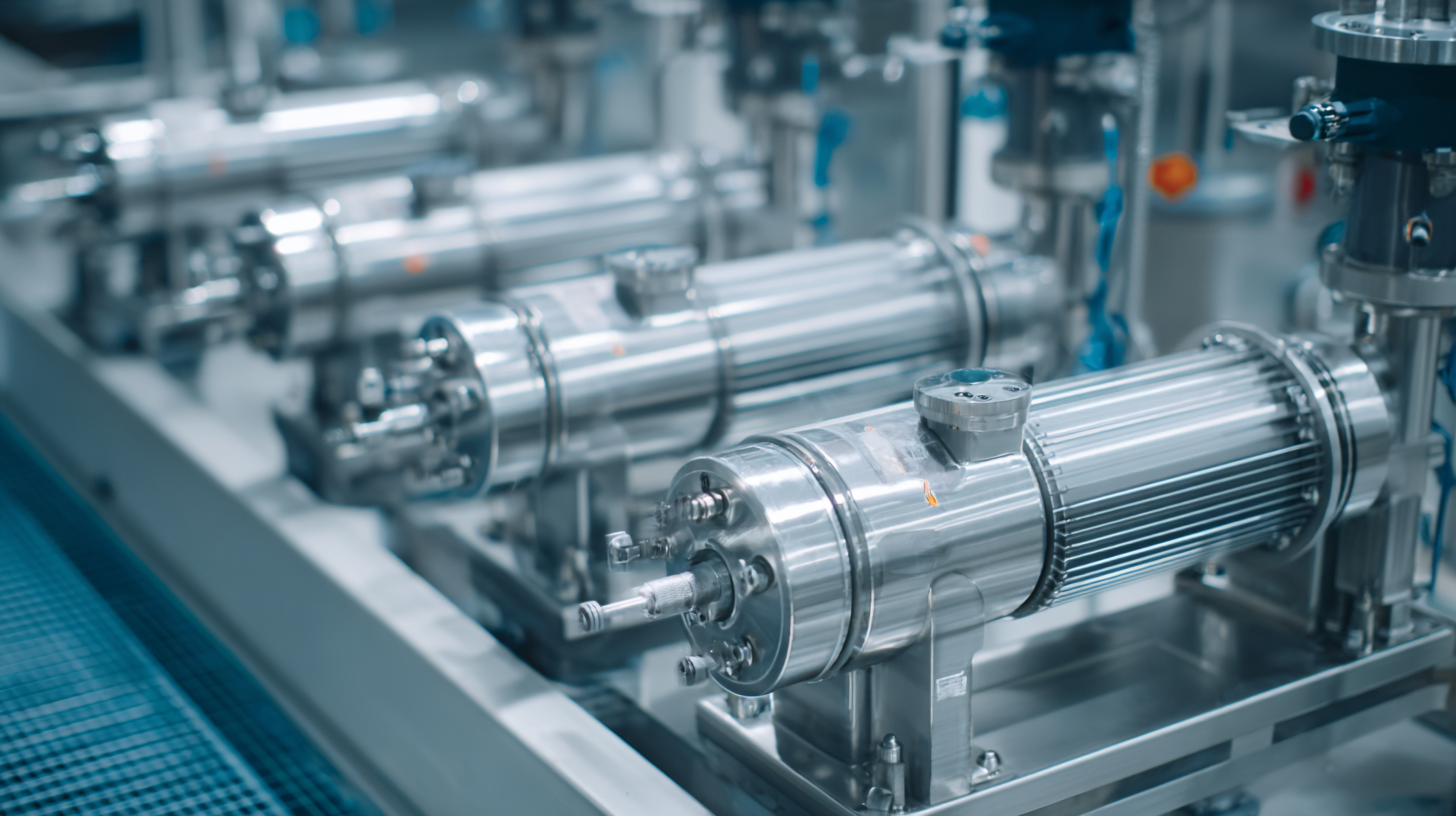

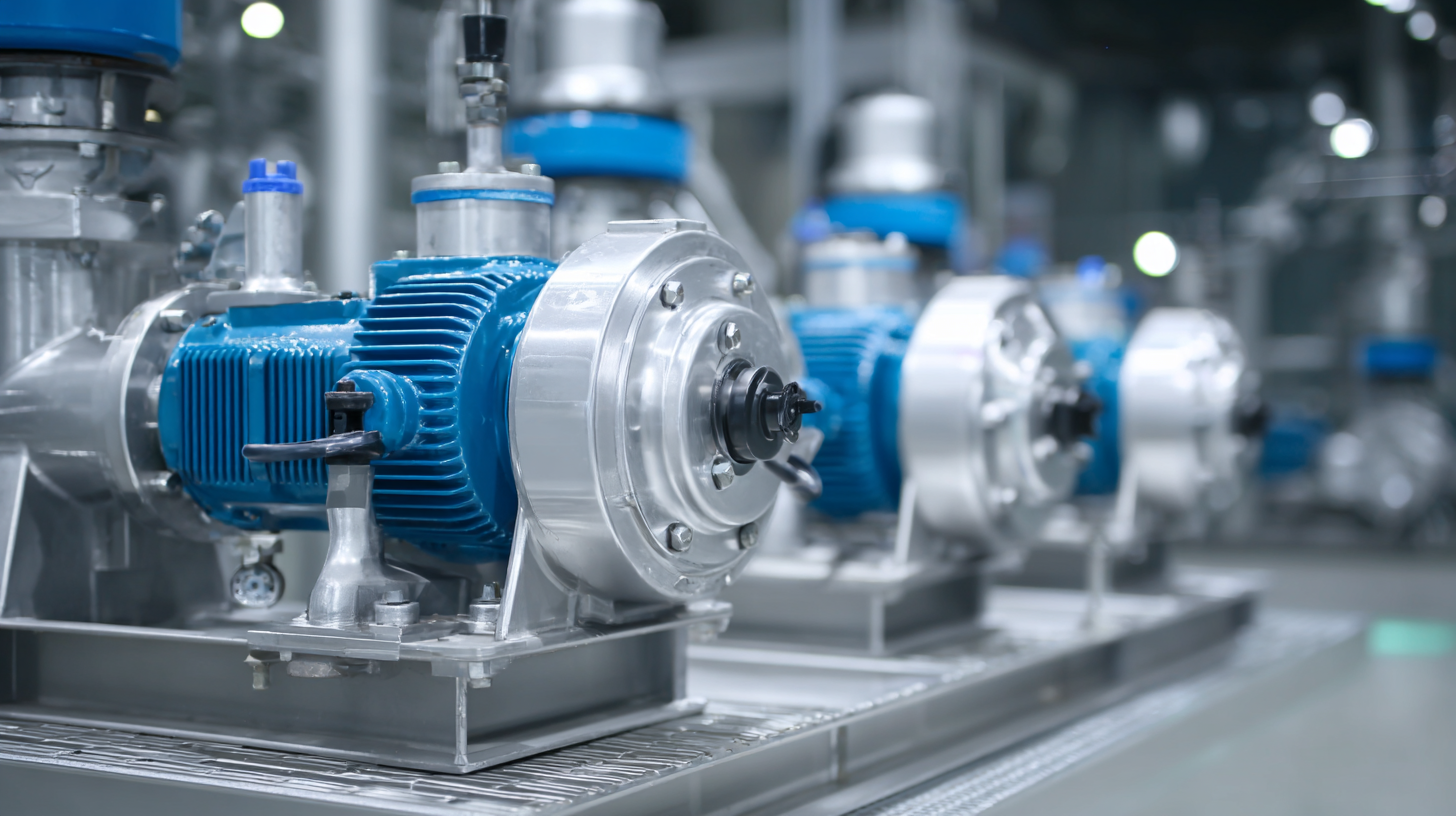

Chemical pumps play a crucial role in various industrial sectors, each type designed to accommodate specific needs and applications.

Centrifugal pumps are among the most common, utilizing rotational energy to transfer liquids. They are ideal for handling large volumes of low-viscosity fluids, making them suitable for industries such as water treatment and chemical processing. Their efficiency and ability to maintain a consistent flow rate make them a staple in many operational settings.

On the other hand, positive displacement pumps offer a different mechanism, moving fluid by trapping a fixed amount and forcing it into the discharge pipe. This type is particularly effective for high-viscosity liquids and precise dosing applications, commonly found in the pharmaceutical and food industries.

Diaphragm pumps, a subset of positive displacement pumps, are especially valued for their ability to handle corrosive chemicals safely, ensuring that the integrity of both the pump and the fluid is maintained. Each type of chemical pump brings unique advantages, making it essential for industries to choose the right one based on their specific application requirements.

Tips for Selecting the Right Chemical Pump for Your Needs

When selecting the right chemical pump for industrial applications, it’s essential to consider several key factors to ensure optimal performance and safety. According to a recent report by Research and Markets, the global chemical pump market is expected to reach $12.6 billion by 2025, driven by the increasing demand for efficient and reliable fluid handling solutions. The first step in making an informed choice is to understand the characteristics of the chemicals being pumped, such as viscosity, corrosiveness, and temperature. These properties will dictate the pump materials, design, and type best suited for your application.

Another critical aspect is the pump’s flow rate and pressure requirements. The Hydraulic Institute suggests that selecting a pump capable of meeting the specific flow and pressure demands can enhance efficiency while minimizing energy consumption. Additionally, considering the total cost of ownership, including maintenance and energy costs, is crucial. For instance, magnetic drive pumps offer a significant advantage in reducing leakage and the need for seals, offering a safer and more cost-effective solution in the long run. Careful evaluation of these factors can lead to better choices that enhance operational efficiency and safety in chemical processing environments.

Best Practices for Maintaining Chemical Pumps Efficiently

Maintaining chemical pumps efficiently is crucial for ensuring the reliability and longevity of equipment in industrial applications. Regular maintenance not only safeguards the pumps from unexpected failures but also optimizes their performance, saving time and resources. One of the best practices is to implement a routine inspection schedule, which includes checking for wear and tear, leaks, and unusual noises. This proactive approach allows operators to address issues before they escalate into costly repairs or downtime.

**Tips:** Always refer to the manufacturer’s guidelines for specific maintenance instructions tailored to your pump type. Additionally, consider using predictive maintenance techniques, such as vibration analysis and thermal imaging, to monitor pump health and prevent potential failures.

Another vital step is ensuring the proper lubrication of moving parts. Regularly check lubricant levels and replace or refill as necessary to avoid friction-related damage. Maintaining a clean pump environment is equally important. Contaminants can significantly impact the pump's efficiency; therefore, regular cleaning and inspection of the surrounding area can go a long way in preserving pump integrity.

**Tips:** Use only the recommended lubricants and keep spare parts on hand to minimize downtime during maintenance tasks. Implementing these best practices can greatly enhance the reliability and efficiency of chemical pumps in modern industrial settings.

Emerging Technologies in Chemical Pump Design and Usage

The evolution of chemical pump design in recent years has been significantly influenced by emerging technologies that enhance efficiency, safety, and environmental sustainability. Advanced materials, such as corrosion-resistant alloys and engineered polymers, have improved the durability of pumps, allowing them to handle aggressive chemicals and high temperatures with minimal wear. Furthermore, 3D printing technology has enabled the rapid prototyping of customized pump components, leading to more tailored solutions that can meet specific industrial requirements.

Another noteworthy advancement is the integration of smart technology into chemical pumps. With the advent of IoT (Internet of Things), these pumps can now provide real-time data monitoring, allowing for predictive maintenance and minimizing downtime. Sensors can detect vibrations, flow rates, and pressure levels, which helps operators to optimize performance and address issues before they escalate. This shift towards smarter, more connected systems not only enhances operational efficiency but also supports compliance with increasingly stringent safety and environmental regulations. As industries continue to adopt these innovative designs, the future of chemical pump technology looks promising, paving the way for safer and more sustainable industrial practices.

Related Posts

-

How to Choose the Right Electric Pumps for Your Business Needs

-

Innovative Liquid Pumps: Transforming Industrial Efficiency and Performance

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

How to Optimize Your Injection Pumps for Maximum Efficiency and Performance

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.