What is a Motor Pump and How Does It Work?

Motor pumps play a crucial role in various industries. They are essential for transporting fluids effectively. According to Dr. John Smith, a leading expert in pump technology, “Understanding motor pumps is vital for optimizing fluid dynamics in any application.” His insights reflect the importance of mastering these devices.

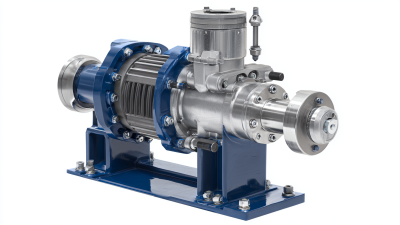

A motor pump combines an electric motor and a pump into one unit. This design allows for efficient operation and energy savings. In sectors such as agriculture and manufacturing, motor pumps are indispensable. They aid in irrigation and fluid transfer processes. However, not all motor pumps perform equally. Factors like installation and maintenance can affect efficiency.

Despite their benefits, many overlook the complexities of motor pumps. Proper training is often lacking, which leads to inefficiencies. Users may not fully grasp how to operate them correctly. Investing in education about motor pumps can prevent costly mistakes. Understanding their mechanics is essential for maximizing performance.

Definition and Functionality of a Motor Pump

A motor pump is a vital device in various industries. It converts electrical energy into mechanical energy, effectively moving fluids from one place to another. These pumps are critical in applications like agriculture, manufacturing, and municipal water supply. According to a report by the Hydraulic Institute, the global market for motor pumps is expected to exceed $30 billion by 2025, highlighting their significance.

The functionality of a motor pump lies in its design. Typically, it consists of a motor, impeller, and volute. The electric motor powers the impeller, which spins rapidly. This motion creates a pressure differential, allowing the pump to draw in liquid. The energy conversion efficiency can greatly affect performance. Some motor pumps may only achieve 60% efficiency, indicating room for improvement.

Maintenance plays a crucial role here. Regular checks can minimize downtime and extend the pump's lifespan. Faulty seals or clogged filters can drastically reduce efficiency. Data indicates that companies neglecting maintenance may face operational costs up to 20% higher. These insights remind industries of the importance of proactive upkeep to avoid unnecessary expenses.

Components of a Motor Pump and Their Roles

A motor pump consists of several key components. Each part plays a crucial role in the pump's operation. The motor provides power, typically converting electrical energy into mechanical energy. It drives the pump’s impeller, which helps move the fluid efficiently.

The impeller is often made of durable materials. It spins rapidly, creating a low-pressure area. This allows the fluid to enter the pump. There’s also a diffuser that helps direct the flow. Sometimes, its efficiency can vary based on the design, which can lead to performance issues.

Additionally, the casing holds everything together. It maintains the pressure and directs the fluid to the desired location. However, the connections may sometimes leak if not properly maintained. Regular checks can prevent this problem. Addressing these issues promptly is vital for optimal performance. Each component, while simple in design, is essential for an effective motor pump system.

What is a Motor Pump and How Does It Work? - Components of a Motor Pump and Their Roles

| Component | Role | Working Principle |

|---|---|---|

| Electric Motor | Drives the pump | Converts electrical energy into mechanical energy |

| Pump Housing | Contains and protects internal components | Holds the fluid being pumped, ensuring it moves efficiently |

| Impeller | Increases fluid flow | Rotates and creates a centrifugal force |

| Suction Pipe | Draws fluid into the pump | Facilitates the entry of fluid to the impeller |

| Discharge Pipe | Transports pumped fluid out of the pump | Channels the fluid flow to the intended location |

| Seal | Prevents leaks | Creates a barrier that stops fluid from escaping |

How Motor Pumps Generate Pressure and Flow

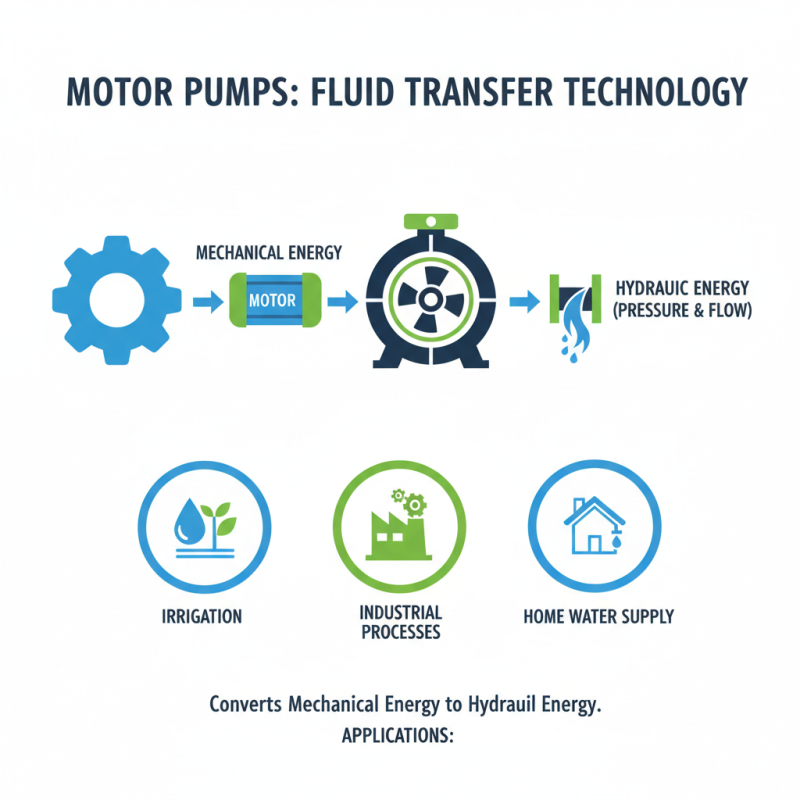

Motor pumps are fascinating devices used to move fluids. They operate by converting mechanical energy into hydraulic energy. The diverse applications include irrigation, industrial processes, and even water supply in homes. Understanding how they generate pressure and flow is essential.

Motor pumps function based on the principles of fluid dynamics. When the motor turns the impeller, it creates a centrifugal force. This force pushes the fluid from the inlet to the outlet. The speed of the impeller directly affects the flow rate. The design of the pump plays a crucial role in how efficiently it operates. Different configurations result in varying pressure levels.

However, it’s noteworthy that not all motor pumps perform flawlessly. Sometimes, cavitation can occur, reducing efficiency. If the input pressure is not adequate, it can create issues. Understanding these flaws is vital for proper maintenance. Small adjustments can lead to improved performance. Awareness of how these pumps work can help users avoid problems and optimize their systems.

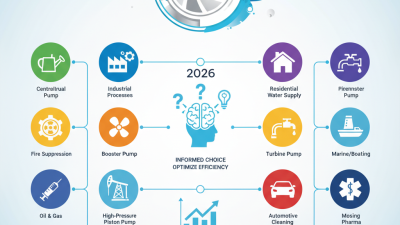

Types of Motor Pumps and Their Applications

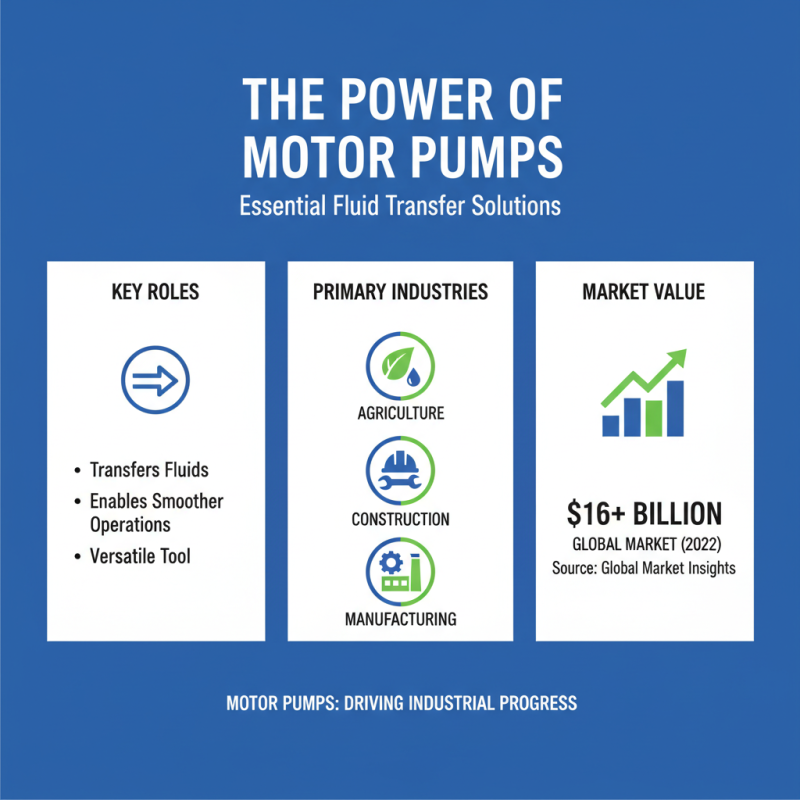

Motor pumps play a crucial role across various industries. They are essential for transferring fluids, enabling smoother operations. Different types of motor pumps suit distinct applications, making them versatile tools in sectors like agriculture, construction, and manufacturing. According to a report by the Global Market Insights, the motor pump market was valued at over $16 billion in 2022, reflecting its importance in industrial applications.

Centrifugal pumps are widely used for their efficiency in moving large volumes of fluid. They are ideal for irrigation and cooling systems. In contrast, positive displacement pumps excel in high-pressure situations. These are often used in oil and gas sectors to enhance extraction processes. Each type has its specific benefits and drawbacks, highlighting the need for careful selection based on required applications.

The reliability of motor pumps is vital. A malfunction can disrupt entire operations. Regular maintenance can mitigate risks. However, some industries overlook this aspect, leading to downtime. Thus, it’s essential to prioritize maintenance schedules to ensure efficiency. Ultimately, making the right choice in motor pumps requires continuous evaluation and reflection on operational needs.

Maintenance and Troubleshooting for Motor Pumps

Motor pumps play a crucial role in various industries, handling liquids efficiently. However, maintenance is key to keeping them operational. Regular inspections can prevent many common issues. According to a report by the International Association for the Maintenance of Way (IAMW), over 30% of motor pump failures are linked to improper maintenance practices. This highlights the need for routine checks.

Monitoring alignment, lubrication, and overall cleanliness are essential. Misalignment can lead to excessive wear, and poor lubrication may cause overheating. Experts suggest that operators should clean the pump regularly and replace worn parts promptly. Routine vibration analysis can also help identify problems early. In a study, it was found that consistent monitoring reduced unexpected failures by nearly 25%.

Troubleshooting starts with understanding symptoms. Unusual noises or vibrations indicate issues. If the pump does not start, check the power supply first. Meanwhile, low flow rates might suggest clogged filters or damaged impellers. Operators often overlook these small details. Ignoring them can lead to larger problems in the future. Keeping accurate records of maintenance can help address recurring issues and improve performance.

Motor Pump Performance Comparison

This chart compares the performance of three different motor pumps based on four key dimensions: Flow Rate, Power Consumption, Efficiency, and Noise Level. These factors are critical in evaluating the suitability of motor pumps for various applications.

Related Posts

-

Harnessing Industry Growth Through Motor Pumps at the 138th Canton Fair 2025

-

10 Essential Tips for Choosing the Best Fluid Pumps for Your Project

-

Understanding the Benefits of Plunger Pumps in Industrial Applications

-

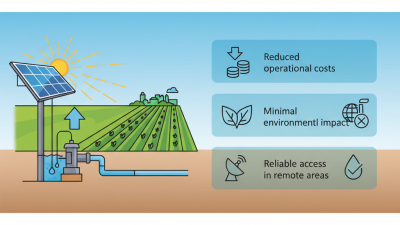

Why a Solar Pump System is the Best Choice for Your Water Needs

-

Top 10 Best Pressure Pumps for Every Application in 2026?

-

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.