How to Minimize Maintenance Costs and Maximize After-Sales Service for the Best Slurry Pump

In the competitive landscape of slurry pump manufacturing, companies must navigate the dual challenges of minimizing maintenance costs while maximizing after-sales service to ensure customer satisfaction and long-term loyalty. According to a report by Research and Markets, the global slurry pump market is projected to reach USD 3.1 billion by 2026, driven by increasing demand across sectors such as mining, construction, and wastewater treatment. Given the inherent complexity and operational demands of slurry pumps, manufacturers must adopt innovative strategies to enhance efficiency and reduce downtime. Effective maintenance programs and robust after-sales service not only contribute to lower operational costs but also increase the overall value proposition of slurry pumps, positioning top manufacturers to thrive in an increasingly globalized market.

Strategies for Reducing Slurry Pump Maintenance Expenses

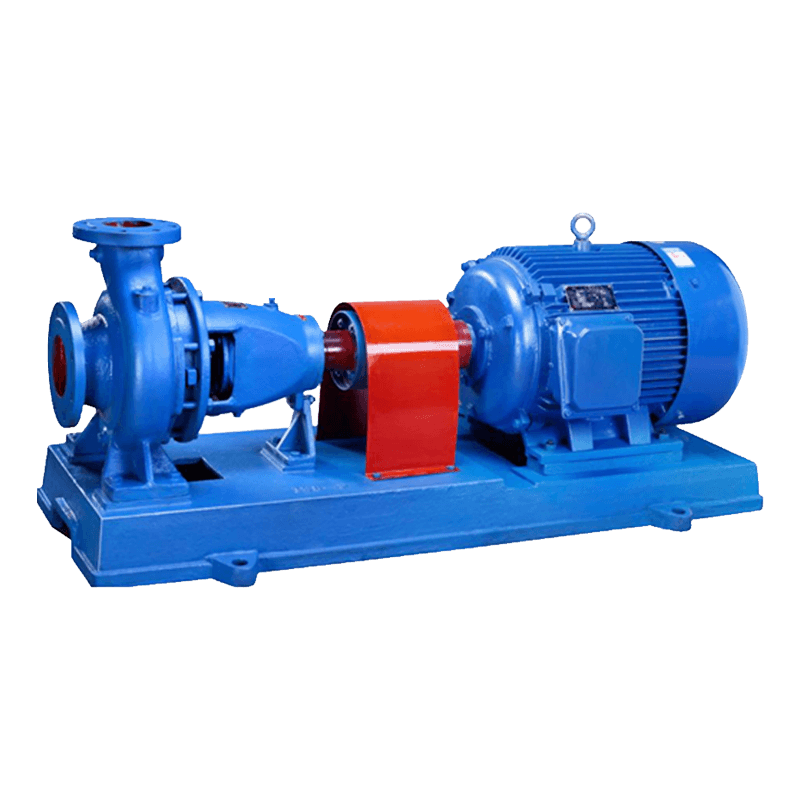

Reducing maintenance expenses for slurry pumps is essential for maximizing efficiency and minimizing downtime in operations. One effective strategy is implementing a regular maintenance schedule that includes routine inspections and servicing. By proactively checking wear components such as seals, bearings, and impellers, operators can identify potential issues before they escalate into costly repairs. Additionally, training staff on proper operation techniques can significantly reduce misuse-related wear, ensuring that the slurry pump functions optimally.

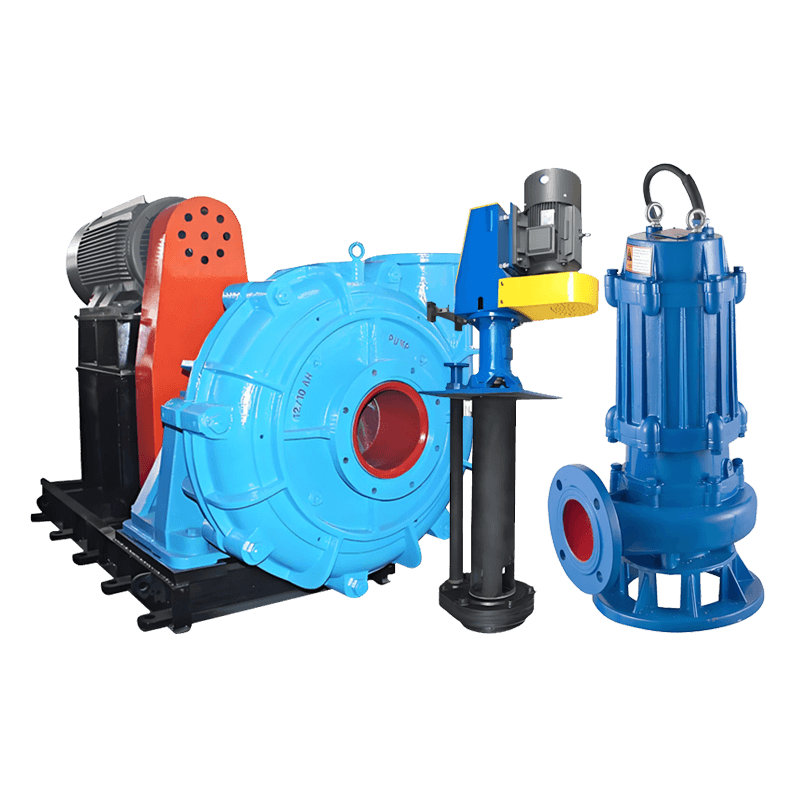

Another key method to minimize maintenance costs is investing in high-quality, durable materials for pump components. Choosing materials that can withstand the specific conditions of the slurry being pumped—such as abrasive solids—can extend the lifespan of the pump. Furthermore, selecting a slurry pump with a modular design allows for easier repairs and part replacements, which can further cut down on maintenance time and costs.

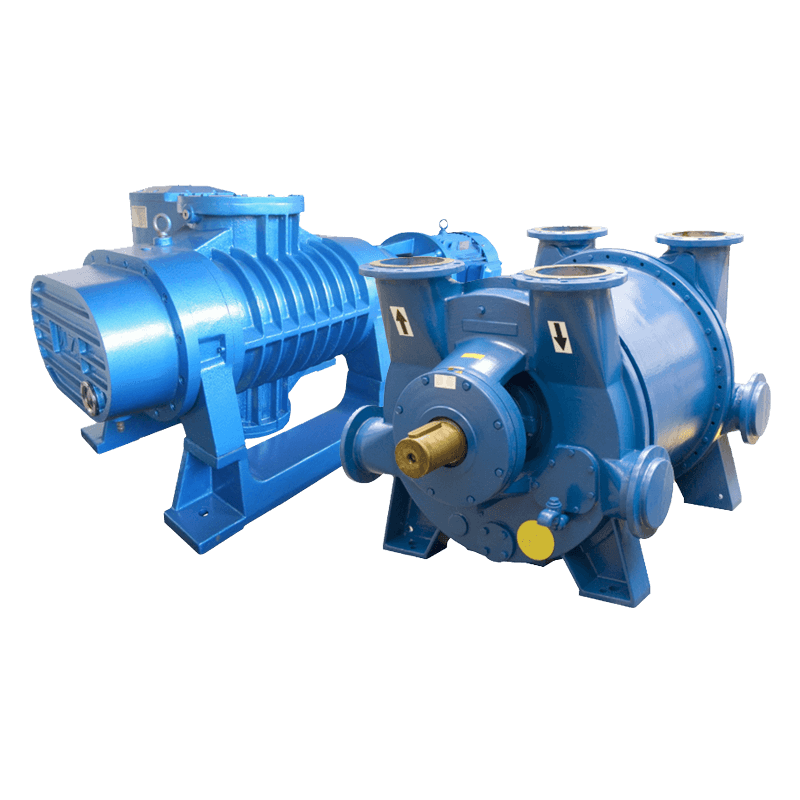

Utilizing advanced monitoring technologies, such as vibration analysis or thermal imaging, can also provide real-time data to predict failures, enabling timely interventions that prevent catastrophic breakdowns and associated expenses.

Understanding Common Slurry Pump Issues and Their Solutions

When it comes to slurry pumps, understanding common issues is crucial for minimizing maintenance costs and maximizing after-sales service. According to a report by Frost & Sullivan, improper pump selection and inadequate maintenance procedures account for up to 30% of operational failures in slurry handling systems. This highlights the importance of a proactive approach to pump management, where regular inspections and adherence to manufacturer guidelines can prevent costly downtimes.

Common problems with slurry pumps include wear and tear due to abrasive materials, cavitation, and incorrect operational parameters. For instance, a study by the American Society of Mechanical Engineers (ASME) indicates that abrasion can decrease the lifespan of a slurry pump by over 50% if not addressed promptly. By utilizing advanced materials and coatings, operators can enhance the durability of their pumps while regular training on operational efficiency will help minimize errors that lead to failure. Solutions such as predictive maintenance technology further aid in identifying potential issues before they escalate, thereby saving costs significantly and enhancing service delivery post-purchase.

Best Practices for Training Staff on Slurry Pump Maintenance

Training staff on slurry pump maintenance is crucial for minimizing maintenance costs and optimizing after-sales service. Ensuring that your team is well-versed in the operation and upkeep of these pumps not only enhances efficiency but also extends the equipment's lifespan. Here are some best practices for effective training:

First, implement a comprehensive training program that includes both theoretical knowledge and hands-on experience. Encourage staff to participate in workshops and seminars where they can learn about the latest advancements in slurry pump technology and maintenance techniques. This will empower them to quickly identify potential issues and mitigate risks before they escalate.

Additionally, create a resource library with manuals, troubleshooting guides, and maintenance schedules easily accessible to all employees. Regularly update this library with new information and conduct refresher courses to keep everyone informed. Finally, foster a culture of open communication where team members can share their experiences and learn from each other. This will lead to better problem-solving and a collaborative approach to maintaining your slurry pumps effectively.

Maintenance Costs vs. After-Sales Service Effectiveness for Slurry Pumps

The Role of Regular Inspections in Minimizing Pump Downtime

Regular inspections play a crucial role in minimizing downtime for slurry pumps, which are essential in various industrial applications. By conducting routine checks, potential issues can be identified before they escalate into major failures. These inspections allow operators to monitor key components such as seals, bearings, and impellers, ensuring optimal performance and extending the pump's lifespan.

Implementing a scheduled maintenance program enhances the efficiency of slurry pumps and reduces overall maintenance costs. Operators can anticipate wear and tear, allowing for timely replacements or repairs, which prevent unplanned outages. Moreover, regular inspections increase the reliability of the pump and foster trust in the after-sales service provided by manufacturers. This proactive approach not only safeguards productivity but also assists in maintaining a consistent operational flow, ultimately benefiting the entire production process.

How to Minimize Maintenance Costs and Maximize After-Sales Service for the Best Slurry Pump - The Role of Regular Inspections in Minimizing Pump Downtime

| Inspection Frequency (Days) |

Maintenance Cost ($) |

Downtime (Hours) |

After-Sales Service Response Time (Hours) |

Customer Satisfaction (%) |

| 30 |

500 |

5 |

2 |

90 |

| 60 |

750 |

12 |

4 |

85 |

| 90 |

1000 |

20 |

6 |

80 |

| 120 |

1250 |

25 |

8 |

75 |