Top 10 Liquid Pump Tips You Should Know for Better Efficiency?

In the world of liquid pump technology, efficiency is crucial. Mark Thompson, a well-respected expert in the liquid pump industry, once stated, "A small change in operation can lead to significant improvements in performance." This insight resonates deeply as we explore the top ten tips for optimizing liquid pump efficiency.

Liquid pumps serve various industries, from manufacturing to agriculture. Their efficiency impacts cost and productivity directly. Many users overlook simple adjustments that could enhance performance. Regular maintenance and correct sizing are often ignored. Ignoring these aspects can hinder your system’s overall potential, leading to wasted energy and resources.

Understanding how to optimize your liquid pump can seem daunting. However, even minor tweaks can yield substantial benefits. It is essential to stay informed. Embracing best practices will ultimately lead to a more effective liquid pump system. Remember, in this rapidly evolving field, complacency can be detrimental. Every action counts toward improving your pump's efficiency.

Understanding Liquid Pump Efficiency: Key Concepts

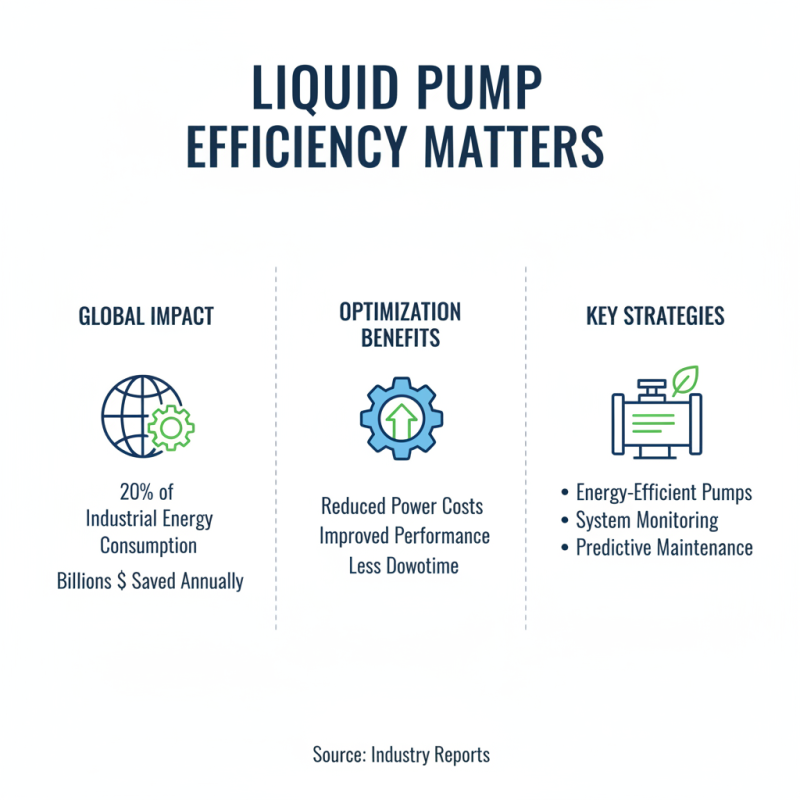

Understanding liquid pump efficiency is crucial for optimizing performance in various industries. Pumps account for a significant portion of energy consumption—up to 20% in some sectors. Each year, billions of dollars are spent on power costs, making efficiency improvements highly beneficial.

One key concept is the "Pump Best Efficiency Point" (BEP). At this point, the pump operates with minimal energy loss. Therefore, it's vital to select pumps that match the specific application requirements. An analysis of industry reports indicates that operating a pump at or near its BEP can enhance efficiency by 10-20%. Neglecting this can lead to increased wear and tear, resulting in higher maintenance costs.

Moreover, factors such as cavitation and fluid viscosity impact performance. Cavitation can cause severe damage to pump components and reduce efficiency. A study found that over 40% of pumps operate below optimal performance due to improper sizing and installation. Regular maintenance is also critical; reports suggest that 30% of system inefficiencies stem from neglected or outdated equipment. Understanding these nuances allows for better decision-making in pump design and operation.

Selecting the Right Liquid Pump for Your Application

Selecting the right liquid pump is crucial for efficiency. Many factors come into play when making this choice. The type of liquid is essential. Viscosity, corrosiveness, and temperature affect performance. A thicker liquid may require a more robust pump design.

Additionally, consider the flow rate needed for your application. Too low a flow rate can lead to inefficiencies. However, an overly high flow rate can be wasteful. It's a balance that takes time to figure out.

Don't overlook the installation site. Space limitations can complicate pump selection. Noise levels and maintenance access should also influence your decision. It's okay to revisit choices. Making adjustments is part of the process. This reflection can lead to better solutions in the long run.

Maintenance Practices to Enhance Pump Performance

When it comes to maintaining liquid pumps, regular upkeep is crucial. Cleanliness is key. Make sure to remove any dirt or debris. This simple step can prevent major issues later. Keep an eye on seals and gaskets. A small crack can lead to leaks, reducing efficiency.

Monitor temperature closely. Overheating can cause wear and tear. If you notice unusual sounds, investigate immediately. It might be a sign of friction or misalignment. Address these problems quickly to avoid further damage. Adjust pump settings according to the liquid being pumped. This can greatly increase efficiency.

Consider inspecting the pump’s performance periodically. Use gauges to check pressure levels. If they are off, something may be wrong. Don’t ignore small changes. They often lead to larger issues. By being proactive, you can save time and money in the long run. Keeping a maintenance log can help track these changes. It allows you to spot trends over time.

Top 10 Liquid Pump Tips You Should Know for Better Efficiency

| Tip Number | Tip Description | Expected Efficiency Gain (%) | Implementation Time (Hours) | |||

|---|---|---|---|---|---|---|

| 1 | Regularly check and replace worn seals | 10 | 2 | |||

| 2 | Align pump and motor properly | 15 | 4 | |||

| 3 | Optimize impeller design | 20 | 10 | |||

| 4 | Maintain proper fluid viscosity | 12 | 3 | |||

| 5 | Minimize suction lift | 18 | 5 | |||

| 6 | Inspect and clean filters and strainers | 10 | 7 | Monitor vibration levels | 15 | 2 |

| 8 | Use variable frequency drives for speed control | 25 | 8 | |||

| 9 | Conduct thermal imaging to detect hot spots | 12 | 6 | |||

| 10 | Train personnel on proper pump operation | 15 | 4 |

Common Issues That Affect Liquid Pump Efficiency

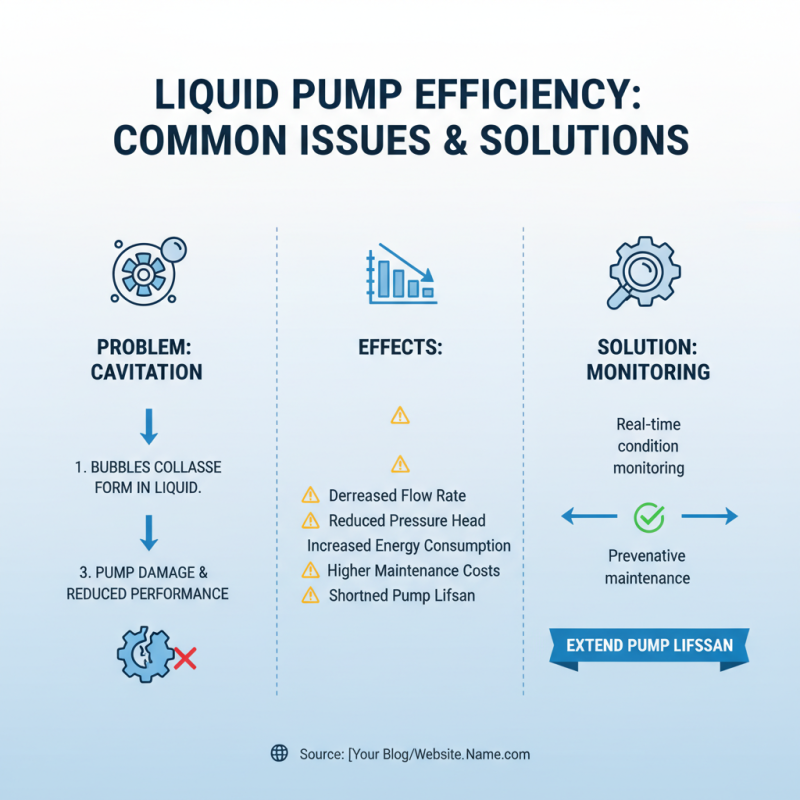

Liquid pumps are essential in various industries. However, several common issues can significantly affect their efficiency. One major problem is cavitation, which occurs when vapor bubbles form in the liquid. These bubbles can collapse violently, damaging the pump. This often leads to reduced performance and increased maintenance costs. Monitoring pump conditions can help prevent cavitation and extend its lifespan.

Another issue is improper pump sizing. A pump that is too large or small can lead to inefficiencies. Oversized pumps waste energy, while undersized pumps may not meet the needed flow rates. It's crucial to evaluate the specific requirements before selecting a pump. Regular maintenance also plays a key role. Neglecting it can result in wear and tear, affecting pump efficiency. Small leaks or clogs can have extensive impacts over time. Refining these areas can significantly improve a pump's performance. Keep an eye on these common issues to maintain optimal efficiency.

Tech Innovations for Improving Pump Efficiency

Innovative technologies are transforming liquid pump efficiency. Modern designs focus on energy consumption and performance. One emerging trend is the integration of smart sensors. These sensors provide real-time data. They help operators monitor pump performance and detect issues early.

Another interesting development is the use of advanced materials. These materials can withstand harsh conditions. They reduce wear and tear on pumps, leading to longer lifespans. Additionally, variable frequency drives (VFDs) are becoming more common. VFDs allow pumps to adjust speed based on demand. This adaptability leads to significant energy savings.

However, with technology comes complexity. Operators may struggle to adapt to new systems. It’s essential to provide adequate training. Maintenance remains a challenge, too. Regular checks are necessary. Neglecting this can lead to inefficiencies and higher costs. Embracing these innovations can significantly enhance pump efficiency, but a careful approach is crucial.

Related Posts

-

What is the Functionality Behind Liquid Pumps in Modern Industries

-

Top 5 Electric Diaphragm Pumps: Key Features and Benefits Explained

-

Exploring Check Valve Innovations at the 2025 China Import and Export Fair

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.