Why Are Industrial Pumps Essential for Manufacturing Efficiency?

Industrial pumps play a crucial role in manufacturing efficiency. According to Mark Thompson, an expert in fluid dynamics, "Industrial pumps are the heartbeat of manufacturing processes." They ensure the smooth flow of liquids and materials in factories. Without them, operations would face significant disruptions.

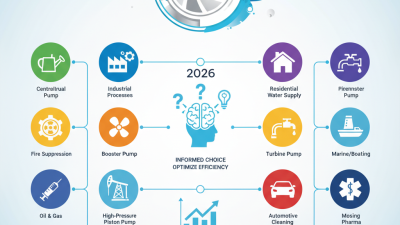

In industries ranging from food processing to chemical manufacturing, every second counts. Industrial pumps move fluids at precise rates, impacting productivity directly. Pump selection often determines energy consumption and operational costs. Choosing the right pump can lead to substantial energy savings and improved efficiency.

However, many manufacturers overlook the importance of maintenance. Neglected pumps can lead to leaks and increased downtime. Regular inspections and timely repairs are essential. Understanding the specific needs of the system can enhance pump performance significantly. Ignoring these aspects can cost businesses in the long run. Every detail matters in the quest for manufacturing excellence.

Importance of Industrial Pumps in the Manufacturing Sector

Industrial pumps play a crucial role in the manufacturing sector. They are responsible for moving fluids through various processes. From transferring chemicals to providing cooling solutions, pumps ensure operations run smoothly. In any manufacturing plant, a malfunctioning pump can lead to significant delays and increased costs.

The efficiency of production often hinges on these pumps. Quality machinery maintains the flow of materials, which directly impacts output. A sudden breakdown can cause production lines to stop completely. This results in wasted time and resources. Yet, many manufacturers sometimes overlook regular maintenance when the system seems to be working fine.

Choosing the right pump is vital. The type of fluid and required pressure determine the best option. While some plants focus on cost, neglecting pump efficiency can be detrimental. The balance between cost and efficiency is a challenge. Manufacturers must reflect on these choices and understand the long-term effects on productivity. Ultimately, well-maintained pumps contribute significantly to manufacturing success.

Why Are Industrial Pumps Essential for Manufacturing Efficiency?

| Pump Type | Application | Efficiency (%) | Maintenance Frequency (Months) | Typical Industries |

|---|---|---|---|---|

| Centrifugal Pump | Water Transfer | 85% | 12 | Food & Beverage, Chemical |

| Positive Displacement Pump | Viscous Liquid Transfer | 75% | 6 | Oil & Gas, Pharmaceutical |

| Gear Pump | Fuel Transfer | 80% | 9 | Automotive, Petrochemical |

| Diaphragm Pump | Chemical Transfer | 70% | 12 | Water Treatment, Mining |

| Submersible Pump | Waste Water Management | 90% | 24 | Construction, Municipal |

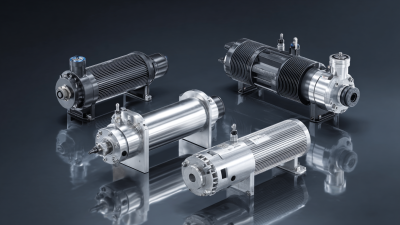

Types of Industrial Pumps Used in Different Manufacturing Processes

Industrial pumps play a pivotal role in various manufacturing sectors. Different types of pumps suit unique processes. Understanding these can enhance efficiency significantly.

Centrifugal pumps are common for fluids with low viscosity. They operate by converting rotational energy into fluid movement. They're ideal for water, chemicals, and other liquids. However, they may struggle with slurries or viscous materials, leading to inefficiencies.

Positive displacement pumps are designed for thicker fluids. They move a fixed volume with each cycle. This consistency is vital in chemical and food manufacturing. While reliable, they require careful maintenance to avoid wear and tear. An overlooked issue can cause costly downtime.

Tips for choosing the right pump: Assess the fluid's viscosity first. Check for compatibility with your process. Regular maintenance can prevent problems. Always stay informed about emerging technologies. They might offer better efficiency and performance.

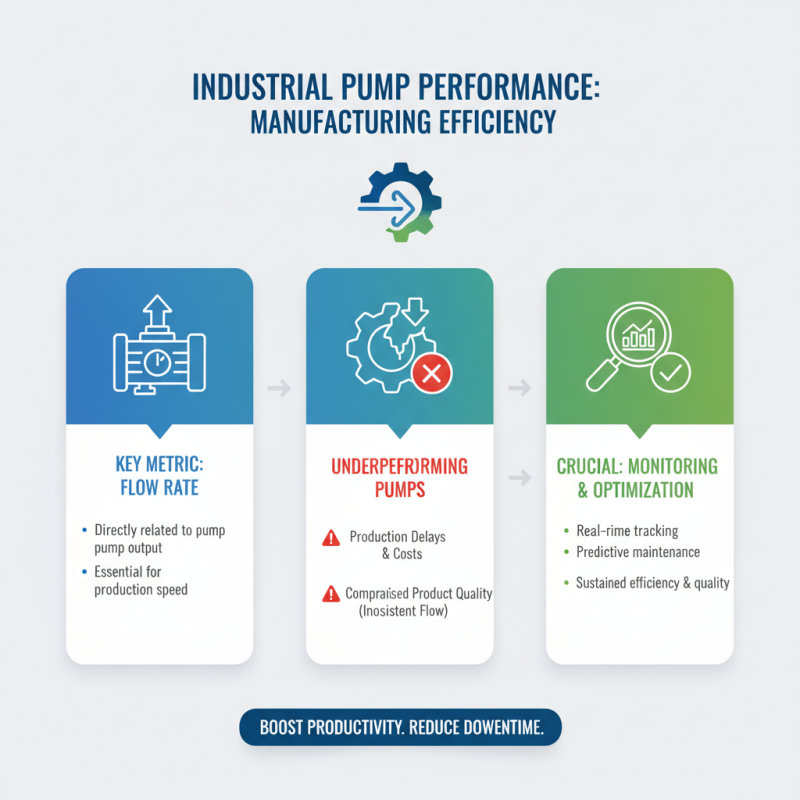

Key Efficiency Metrics Influenced by Pump Performance

In manufacturing, the performance of industrial pumps plays a crucial role in efficiency metrics. Flow rate is one key metric that directly relates to pump performance. A pump that underperforms can severely affect the production line. This can lead to delays and increased operational costs. If the flow rate is inconsistent, product quality can suffer. It’s vital to monitor this metric closely.

Another important aspect is energy consumption. Inefficient pumps can drive up energy costs significantly. This is often overlooked. Manufacturers should evaluate their pumps periodically to ensure they operate within optimal energy ranges. Sometimes, older models may consume much more energy than newer, advanced designs. A simple change can lead to better performance and lower costs.

Reliability is a further metric that impacts overall efficiency. If pumps frequently fail, downtime increases, disrupting workflow. Regular maintenance is essential, yet it’s often neglected. Thinking about maintenance might also lead to unnecessary expenses. Therefore, manufacturers must weigh the costs of upkeep against potential losses from equipment failure. Streamlining pump performance is not just about profits; it's about creating a sustainable operation.

Economic Impact of Pump Reliability on Manufacturing Costs

Industrial pumps play a critical role in manufacturing processes. Their reliability directly affects production efficiency and operational costs. When a pump fails, the impact is immediate. Downtime can lead to delays and increased labor costs. This scenario highlights the importance of choosing reliable pumps in production lines.

The economic impact of pump reliability is evident in various sectors. A malfunctioning pump can halt operations, causing a ripple effect throughout the supply chain. This disruption often leads to wasted materials and lost revenue. Additionally, maintenance expenses can stack up when repairing or replacing pumps frequently. Businesses might overlook these costs, thinking short-term fixes are sufficient. In reality, investing in high-quality pumps saves money in the long run.

Attention to pump maintenance can prevent costly issues. Regular checks and prompt repairs contribute to operational longevity. However, even the best pumps require oversight and vigilance. Managers must ensure staff is trained and knowledgeable about handling these vital machines. A proactive approach often results in better manufacturing outcomes. Yet, many companies still underestimate the importance of this. Reflecting on past mistakes can provide valuable lessons for future operations.

Recent Innovations in Pump Technology Driving Efficiency Improvements

Recent advancements in pump technology are revolutionizing the manufacturing sector. According to a report by the National Association of Manufacturers, efficiency improvements can lead to a 20% reduction in operational costs. This is largely due to innovative designs that enhance energy efficiency and reliability. New materials and digital monitoring systems allow for smarter operations.

Additionally, variable frequency drives (VFDs) enable pumps to adjust their speed according to demand. A study by the American Society of Mechanical Engineers noted that integrating VFDs can achieve energy savings of 30% or more. This presents a significant opportunity for manufacturing plants to lower energy consumption. However, some facilities still rely on outdated systems, thus missing out on potential savings.

While innovations give an edge, they also highlight a challenge. The rapid pace of technological change can overwhelm traditional maintenance practices. Many companies find it hard to keep up with the latest trends. Stagnation in adopting new systems can lead to inefficiencies and lost revenue opportunities. As technology evolves, staying informed and adaptable becomes crucial for manufacturers aiming to boost efficiency.

Industrial Pumps Efficiency Improvements Over Recent Years

This chart illustrates the percentage of efficiency improvements in industrial pump technology from 2018 to 2023. The data reveals a significant upward trend, highlighting recent innovations that have greatly enhanced manufacturing efficiency.

Related Posts

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

How to Effectively Pump Water for Your Home Garden?

-

Harnessing Industry Growth Through Motor Pumps at the 138th Canton Fair 2025

-

Top 2025 Pressure Pumps: Innovative Solutions for Every Need

-

Top 10 Best Pressure Pumps for Every Application in 2026?

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.