Understanding the Importance of Chemical Metering Pumps in Industrial Applications

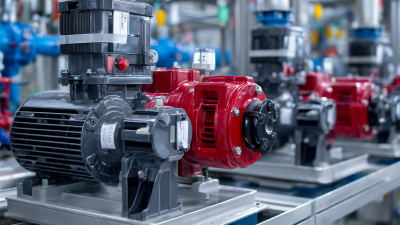

In the realm of industrial applications, the significance of chemical metering pumps cannot be overstated.

These precision devices are crucial for accurately dispensing chemicals needed for processes such as water treatment, pharmaceuticals, and food production.

According to a report from MarketsandMarkets, the global chemical metering pump market is projected to reach USD 3.84 billion by 2025,

growing at a CAGR of 6.3% from 2020 to 2025. This growth is driven by increasing demand for water purification and stringent regulations on wastewater management,

highlighting the pivotal role these pumps play in ensuring compliance and operational efficiency.

With advancements in technology and automation, understanding how to effectively utilize and maintain chemical metering pumps is essential for maximizing their performance and achieving optimal safety standards in various industrial settings.

In the realm of industrial applications, the significance of chemical metering pumps cannot be overstated.

These precision devices are crucial for accurately dispensing chemicals needed for processes such as water treatment, pharmaceuticals, and food production.

According to a report from MarketsandMarkets, the global chemical metering pump market is projected to reach USD 3.84 billion by 2025,

growing at a CAGR of 6.3% from 2020 to 2025. This growth is driven by increasing demand for water purification and stringent regulations on wastewater management,

highlighting the pivotal role these pumps play in ensuring compliance and operational efficiency.

With advancements in technology and automation, understanding how to effectively utilize and maintain chemical metering pumps is essential for maximizing their performance and achieving optimal safety standards in various industrial settings.

Choosing the Right Chemical Metering Pump for Your Application Needs

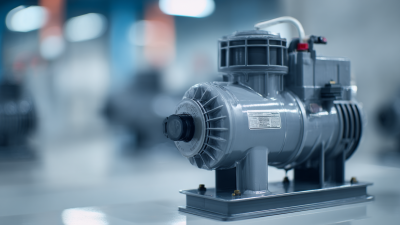

When selecting a chemical metering pump for industrial applications, understanding the specific needs of your operation is crucial. According to a recent report by Grand View Research, the global market for chemical metering pumps is expected to reach $4.43 billion by 2025, driven by the increasing demand for precise fluid control in various industries. Factors such as pump type, material compatibility, and flow rate should guide your decision-making process. Positive displacement pumps, for instance, offer high accuracy and reliability for aggressive chemicals, making them ideal for applications in water treatment and petrochemical sectors.

Additionally, the evolving technology in chemical metering pumps, such as smart pumping systems and IoT integration, requires that companies carefully consider their operational demands. Research from MarketsandMarkets indicates that the demand for digital metering solutions is projected to grow at a CAGR of 6.5% from 2020 to 2025. These technologies can provide real-time monitoring and increased efficiency, ultimately leading to reduced operational costs. Choosing the right chemical metering pump means not just considering current batch requirements but also anticipating future needs, ensuring scalability and adaptability in a rapidly changing industrial landscape.

Understanding Key Features of Chemical Metering Pumps

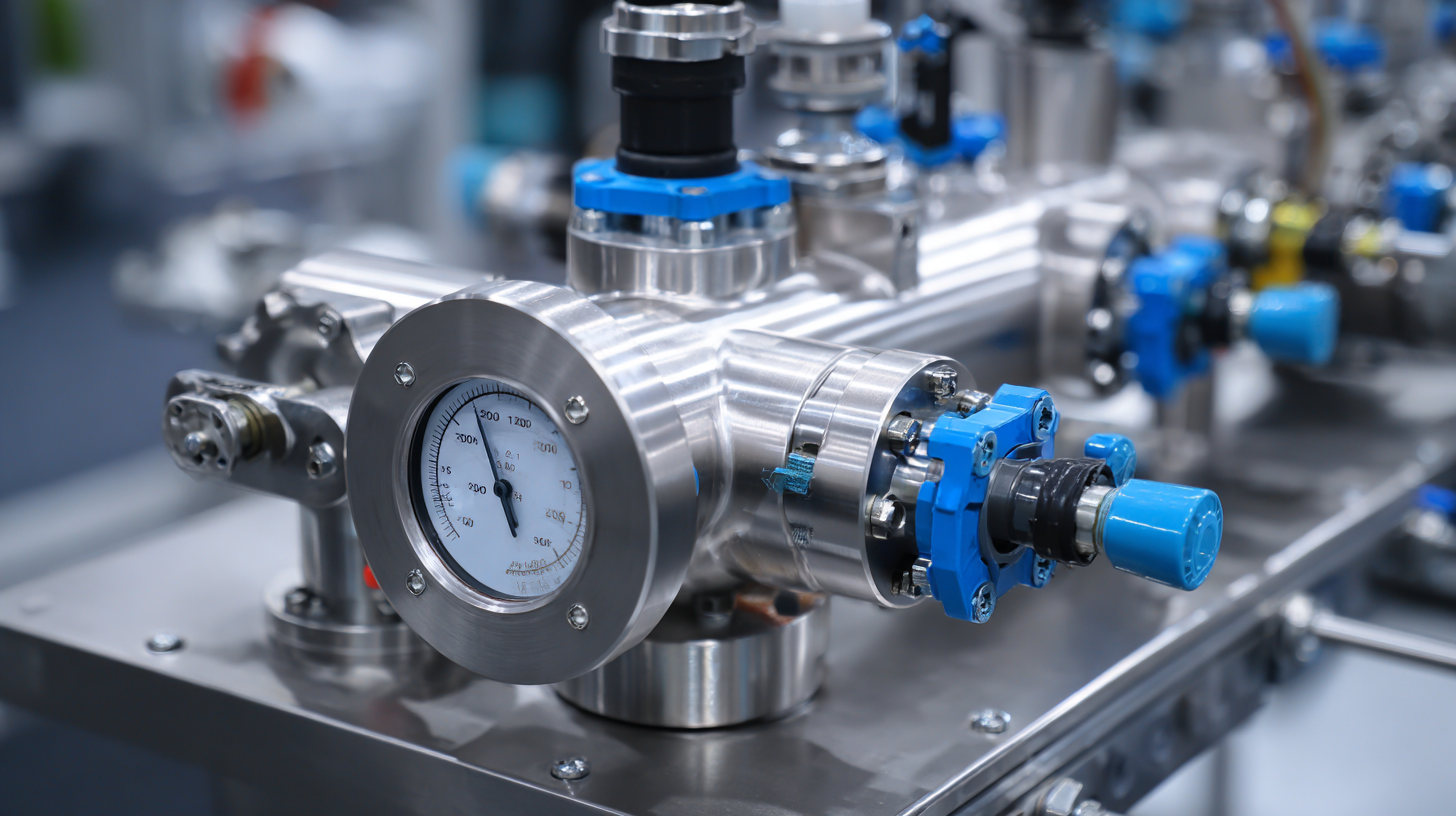

Chemical metering pumps play a crucial role in various industrial applications by enabling precise control over the dispensing of chemicals. One of the key features of these pumps is their ability to deliver accurate and consistent flow rates, which is essential for processes that require exact chemical concentrations. This precision not only helps in maintaining product quality but also ensures compliance with safety and environmental regulations.

Another noteworthy feature of chemical metering pumps is their adaptability. These pumps can be designed to handle various chemical properties, including corrosive, viscous, or abrasive substances. Many models also offer adjustable stroke lengths and frequencies, allowing operators to fine-tune the flow rate as per the demands of the specific application. Additionally, advanced monitoring systems are often integrated to provide real-time data on pump performance, enabling early detection of potential issues and minimizing downtime. This versatility and reliability make chemical metering pumps invaluable assets in industries such as water treatment, pharmaceuticals, and food processing.

Maintenance Tips to Ensure Optimal Performance of Metering Pumps

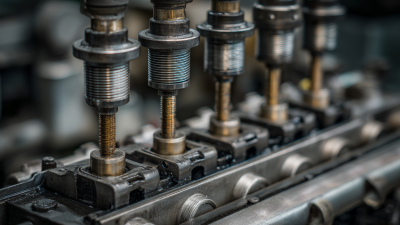

Chemical metering pumps play a crucial role in a variety of industrial applications, where precise dosing of chemicals is essential for optimal process efficiency. To ensure these pumps operate at peak performance, regular maintenance is vital. According to a report by the International Society for Automation (ISA), up to 30% of equipment failures in industrial settings can be attributed to inadequate maintenance, making it imperative for operators to implement effective upkeep strategies.

One of the primary maintenance tips for metering pumps is to regularly inspect and replace the check valves and seals, as these components are critical for preventing leaks and ensuring accurate flow rates. The American Chemical Society (ACS) emphasizes that maintaining the integrity of these components can lead to a reduction in downtime of up to 20%. Additionally, regular calibration checks are essential, as even small deviations in calibration can result in significant changes in chemical concentration, which may negatively impact production quality. Implementing a structured maintenance schedule can enhance reliability and prolong the lifespan of chemical metering pumps, ultimately contributing to overall operational efficiency.

Understanding the Importance of Chemical Metering Pumps in Industrial Applications - Maintenance Tips to Ensure Optimal Performance of Metering Pumps

| Parameter | Optimal Range | Recommended Maintenance Frequency | Common Issues | Troubleshooting Tips |

|---|---|---|---|---|

| Flow Rate | 0.1 - 100 GPH | Monthly | Inconsistent flow | Check for clogs or blockages |

| Pressure | 10 - 100 PSI | Bi-annual | Pressure drop | Inspect seals and fittings |

| Temperature | -10°C to 50°C | Quarterly | Overheating | Ensure proper coolant flow |

| Chemical Compatibility | Specific to application | Annually | Corrosion | Review material choices |

| Lubrication | As per manufacturer | Monthly | Seizing | Check lubricant levels |

Troubleshooting Common Issues in Chemical Metering Pumps

Chemical metering pumps are vital in various industrial applications, enabling precise control over the dosing of chemicals. However, operational challenges can arise, necessitating a thorough understanding of troubleshooting techniques. According to a report by the Chemical Engineering Research & Design journal, approximately 15-20% of downtime in chemical processing plants is attributed to issues with metering pumps. This statistic highlights the need for timely identification and resolution of common problems.

Among the prevalent issues, pump wear and tear, calibration errors, and clogging are often cited. A study published in the Journal of Loss Prevention in the Process Industries found that nearly 30% of pump failures stem from improper maintenance practices. Regular inspections, along with scheduled recalibration, can significantly reduce these occurrences. Additionally, utilizing high-quality materials in pump construction can mitigate the risks of clogging and extend the life of the pump. Addressing these common issues not only enhances operational efficiency but also reduces overall costs and contributes to safer industrial environments.

Evaluating the Cost-Benefit of Chemical Metering Pumps in Industrial Settings

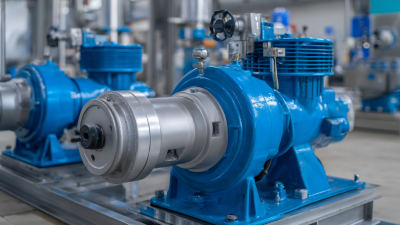

Chemical metering pumps play a pivotal role in industrial settings, especially in water treatment applications where precision and reliability are essential. By accurately delivering chemicals required for treatment, these pumps ensure that processes such as disinfection and nutrient adjustment are performed efficiently. This accuracy not only enhances the effectiveness of water treatment but also minimizes the risk of over or under-dosing, which can lead to operational inefficiencies and potential regulatory non-compliance.

When evaluating the cost-benefit of chemical metering pumps, one must consider both direct and indirect savings. While the initial investment might seem significant, the long-term benefits include reduced chemical waste, lower energy costs, and improved operational efficiency. Moreover, with the increasing presence of chemicals of emerging concern (CECs) in water, the adaptability of metering pumps to handle various chemicals becomes even more valuable. Ultimately, the use of efficient chemical metering pumps can result in substantial savings and contribute to a more sustainable approach in the management of resources within industrial operations.

Related Posts

-

Revolutionizing Efficiency in Oil Fields: The Role of Chemical Injection Systems

-

How to Choose the Right Electric Pumps for Your Business Needs

-

How to Optimize Your Injection Pumps for Maximum Efficiency and Performance

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

Understanding the Different Types of Motor Pumps and Their Applications in Various Industries

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.