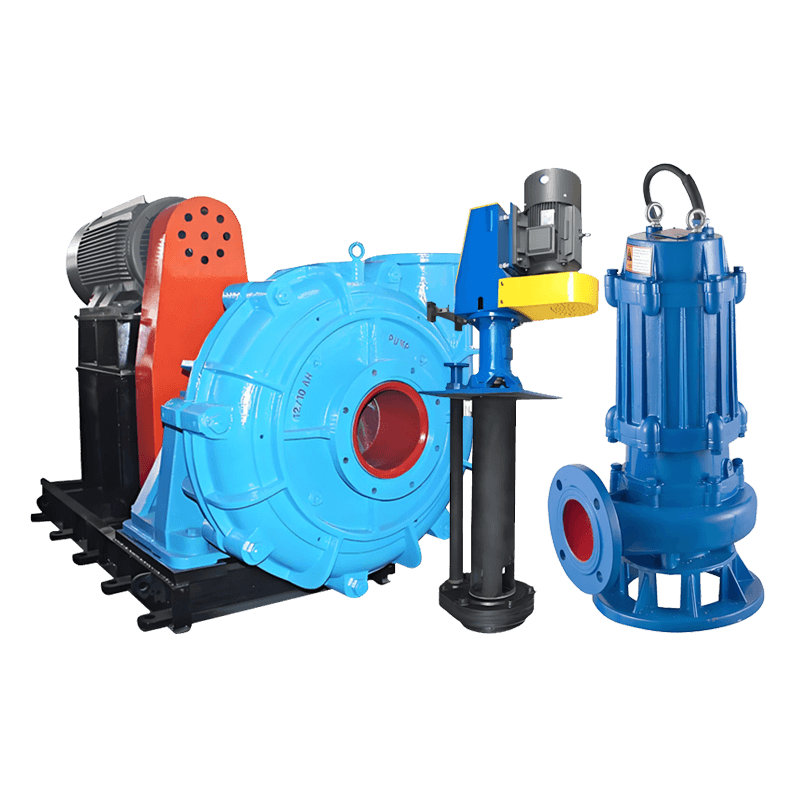

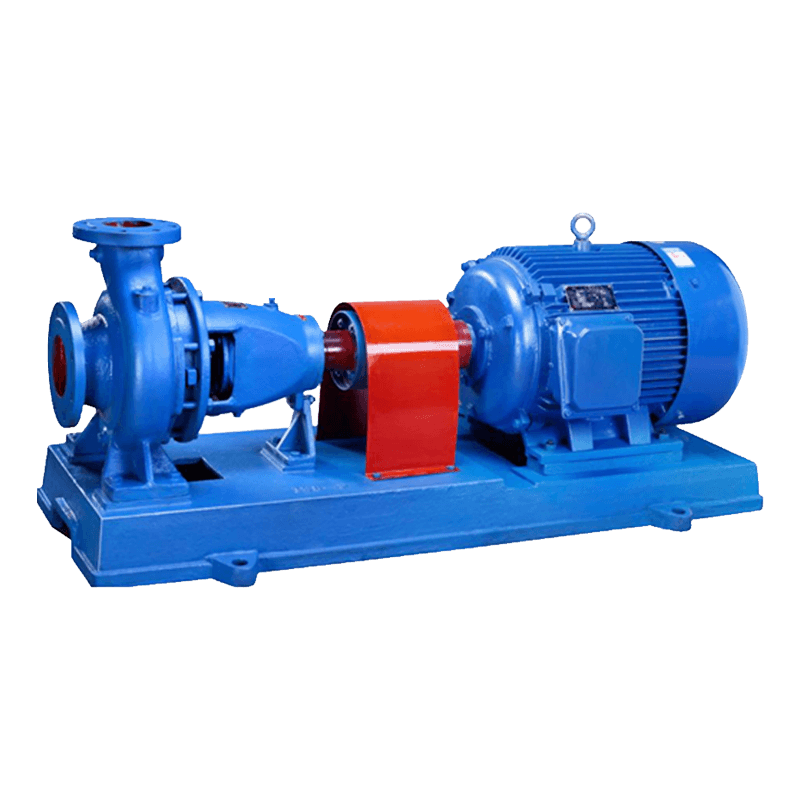

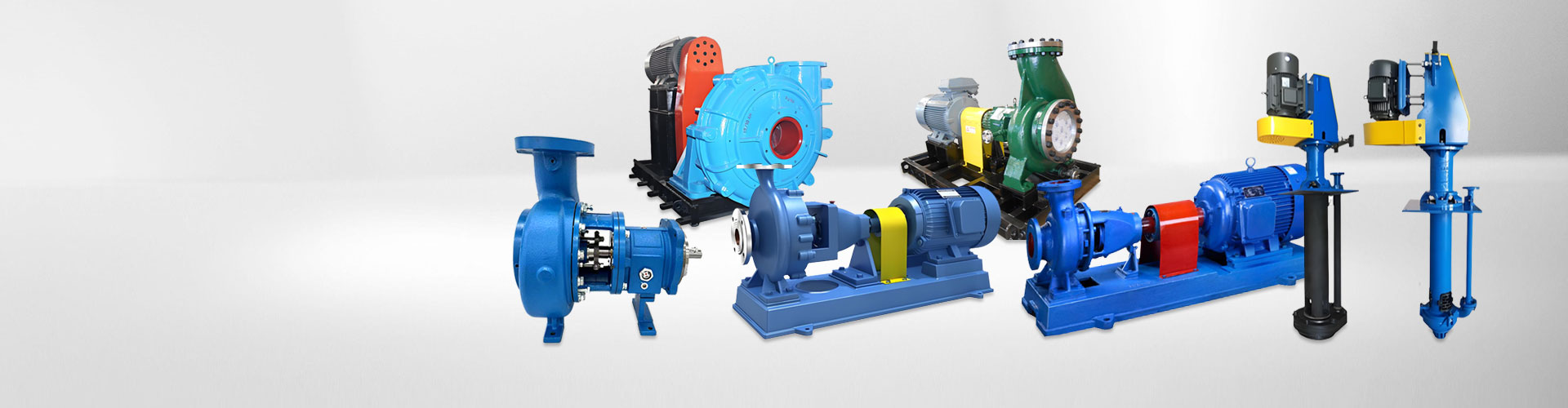

Excellence in Manufacturing from China for Global Centrifugal Pump Parts Supply

In recent years, the global demand for centrifugal pump parts has seen significant growth, driven by the rising need for efficient fluid management across various industries. According to a report by MarketsandMarkets, the centrifugal pump market is projected to reach USD 45.2 billion by 2025, growing at a CAGR of 4.4% from 2020. This expansion emphasizes the crucial role that manufacturing excellence plays in meeting the intricate supply demands for centrifugal pump parts. China, as a leading player in manufacturing capabilities, has positioned itself as a vital supplier in this sector, offering advanced technology and cost-effective solutions. This tutorial aims to delve into the nuances of sourcing high-quality centrifugal pump parts from China, highlighting the best practices, key considerations, and the competitive advantages that come from leveraging China's manufacturing expertise.

Importance of Import and Export Certifications in the Manufacturing Sector

In the competitive landscape of manufacturing, the importance of import and export certifications cannot be overstated, particularly for companies involved in the production and supply of centrifugal pump parts. These certifications serve as a testament to the quality and compliance of manufacturing processes with international standards. According to a report by McKinsey & Company, companies that prioritize quality certifications gain a significant competitive edge, with potential revenue increases of 20% through enhanced trust and market access.

Moreover, the globalization of supply chains emphasizes the need for stringent certification protocols. As per a study from the International Trade Centre, over 60% of manufacturers report facing challenges related to compliance. In the centrifugal pump sector specifically, adherence to certifications such as ISO 9001, which focuses on quality management systems, and CE marking for products sold in the European market, is crucial. These certifications not only ensure product reliability but also facilitate smoother trade relations and reduce barriers to entry in various international markets, effectively driving growth and innovation in the manufacturing sector.

In conclusion, as the demand for high-quality centrifugal pump parts grows globally, manufacturers in China and beyond must invest in securing the appropriate import and export certifications. This focus not only validates their commitment to excellence but also expands their reach in an increasingly competitive global arena.

Key Certifications That Enhance Global Competitiveness for Chinese Pump Parts

In the competitive landscape of global manufacturing, key certifications play a pivotal role in enhancing the competitiveness of Chinese centrifugal pump parts. According to a report by the International Organization for Standardization (ISO), certified products typically see a 20% increase in customer trust and market share. For manufacturers in China, obtaining certifications such as ISO 9001 for quality management and ISO 14001 for environmental management is not just beneficial but essential for gaining international recognition.

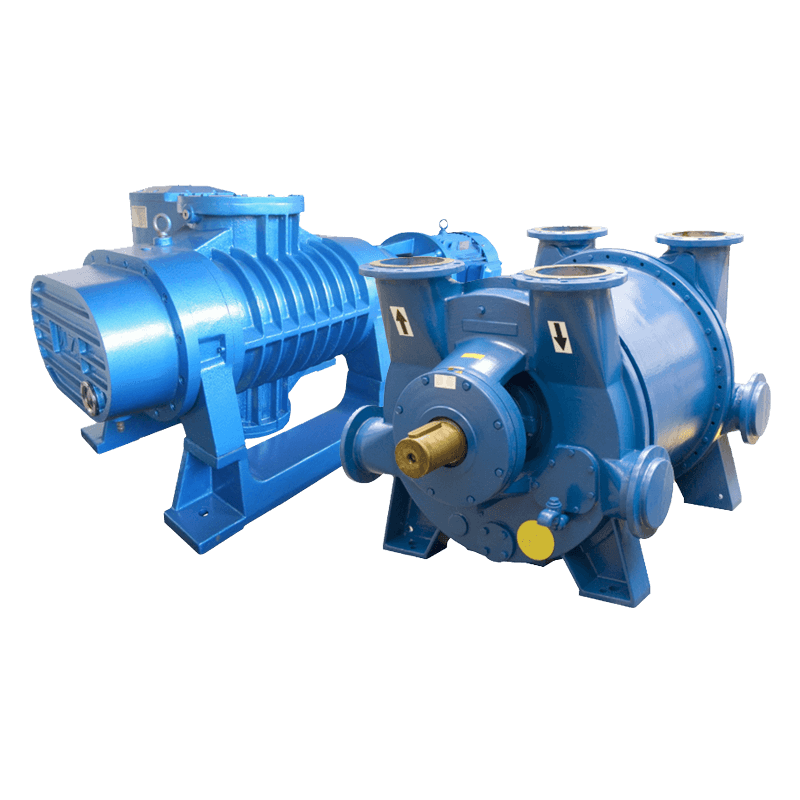

Additionally, Chinese manufacturers are increasingly pursuing the American Petroleum Institute (API) certification, which is particularly crucial in the oil and gas sector. Data from the API indicates that over 80% of global industrial pump purchases consider API compliance a minimum requirement. This certification signifies that the pump parts can meet stringent performance and safety standards, making them more appealing in global markets. By focusing on these certifications, Chinese manufacturers can not only bolster their reputation but also expand their reach within the increasingly demanding global supply chain.

Navigating Regulatory Requirements for International Centrifugal Pump Supply

Navigating the regulatory landscape for international centrifugal pump supply is crucial for manufacturers looking to expand their reach.

According to a report by Research and Markets, the global centrifugal pump market is projected to grow from USD 18.7 billion in 2022 to USD 24.1 billion by 2027, with a compound annual growth rate (CAGR) of 5.3%. This growth underscores the necessity for manufacturers to ensure compliance with varying international standards and regulations, such as ISO 9001 for quality management systems and the relevant API standards for industrial pumps.

Understanding these regulatory requirements is not only vital for market access but also for safeguarding the integrity of products. Non-compliance can lead to significant financial penalties and reputational damage. For instance, the United States Environmental Protection Agency (EPA) has stringent guidelines on emissions and waste management that must be adhered to for pumps used in industrial applications.

By staying informed and proactive about these regulations, companies can position themselves favorably in a competitive global market, ensuring their centrifugal pump parts meet both quality and regulatory standards.

Benefits of Quality Certifications for Manufacturers and End-Users

In 2025, excellence in manufacturing, particularly in producing global centrifugal pump parts from China, will remain crucial for industry players aiming to enhance their market presence. One of the significant advantages of quality certifications is the assurance they offer to both manufacturers and end-users. According to a joint study by McKinsey and NielsenIQ, sustainability-focused products have seen sales growth, indicating that consumers are increasingly willing to spend more on certified products. This trend highlights the importance of Total Quality Management (TQM) in facilitating certification processes and enhancing operational efficiency for manufacturers.

**Tip:** Implement regular audits and training to ensure your team understands quality standards associated with certifications. This not only boosts internal capabilities but also prepares your organization for the evolving customer expectations regarding sustainability.

Investing in single-use technologies in bioprocessing can yield considerable cost and time efficiencies, aligning with industry-wide moves toward more responsible manufacturing practices. Moreover, as demand for high-quality probiotics rises, certification remains vital for assuring the integrity of such products, with experts emphasizing the need for stringent quality measures throughout the production chain.

**Tip:** For manufacturers, establishing robust quality control measures at every production stage can enhance product quality and customer trust. Consider partnering with leading experts to develop a rigorous quality assurance strategy that meets both market demands and regulatory standards.

Excellence in Manufacturing from China for Global Centrifugal Pump Parts Supply

| Certification |

Description |

Benefits for Manufacturers |

Benefits for End-Users |

| ISO 9001 |

Quality Management Systems |

Improved process efficiency, enhanced customer satisfaction |

Assurance of product reliability and quality |

| CE Marking |

Conformity to European Standards |

Access to European markets, increased competitiveness |

Safety assurance and compliance with EU regulations |

| API 610 |

Centrifugal Pump Standard |

Recognition for high-performance and reliability |

Trust in product durability and operational efficiency |

| ASME |

American Society of Mechanical Engineers Certification |

Enhanced engineering practices and product safety |

Assurance of compliance with stringent engineering standards |

| ISO 14001 |

Environmental Management Systems |

Improved resource efficiency and reduced waste |

Commitment to sustainability and reduced environmental impact |

Impact of Compliance on Customer Trust and Market Expansion in Pump Industries

In the competitive landscape of the pump industry, compliance is more than just a regulatory obligation; it serves as a critical pillar for establishing customer trust and facilitating market expansion. Adhering to strict compliance standards not only assures clients of product quality and reliability but also fosters long-lasting relationships built on transparency. For manufacturers, especially those in China supplying centrifugal pump parts to global markets, demonstrating compliance can significantly enhance their brand reputation, making them more appealing to international buyers.

Furthermore, as the market evolves, companies that adopt a Zero Trust Security framework are set to amplify their business growth. This approach secures sensitive data and systems, reassuring customers that their interests are prioritized. By integrating compliance measures with innovative security practices, manufacturers of centrifugal pumps can position themselves as leaders in both trust and technology, driving further expansion into new markets. As customer expectations rise, the alignment of compliance and security may not only define success in the pump industry but also unlock significant growth opportunities worldwide.

Impact of Compliance on Customer Trust and Market Expansion in Pump Industries