10 Essential Tips for Choosing the Best Fluid Pumps for Your Project

When embarking on a project that requires the use of fluid pumps, the selection process can seem daunting due to the wide variety of options available. Fluid pumps are essential components in numerous industries, from agriculture to manufacturing, where they are employed to transfer, compress, or control the flow of liquids. Choosing the right fluid pump not only impacts the efficiency of your operation but also ensures optimal performance, reliability, and safety throughout the project's duration.

In this guide, we will highlight ten essential tips to assist you in making an informed decision when selecting fluid pumps for your specific applications. From understanding the various types and their functionalities to considering factors such as flow rate, pressure requirements, and material compatibility, it's crucial to approach your choice with a clear strategy. By following these guidelines, you can navigate the complexities of fluid pump selection and find the perfect match for your project needs, enhancing both productivity and cost-effectiveness.

Understanding the Different Types of Fluid Pumps Available

When embarking on a project that requires fluid transfer, understanding the various types of fluid pumps is crucial for making an informed choice. Fluid pumps can generally be classified into two primary categories: positive displacement pumps and dynamic pumps. Positive displacement pumps, such as gear and diaphragm pumps, operate by trapping a fixed amount of fluid and forcing it into the discharge pipe, making them ideal for handling viscous liquids and delivering a steady flow rate. These pumps are particularly effective in applications requiring precise dosing and pressure control.

Dynamic pumps, on the other hand, utilize kinetic energy to move fluid through the system. Centrifugal pumps, a common type of dynamic pump, rely on rotational energy to increase fluid velocity. They are best suited for low-viscosity liquids and applications where high flow rates are essential. However, dynamic pumps can struggle with variations in fluid properties, so careful consideration of the fluid’s characteristics is necessary.

Choosing the right type of pump involves assessing factors such as the fluid's viscosity, temperature, and the desired flow rate. Each type of pump has its unique advantages and limitations, making it vital to match the pump to the specific requirements of your project.

Evaluating Pump Materials for Compatibility with Fluids

When selecting fluid pumps for your project, evaluating pump materials for compatibility with the fluids being handled is critical. Different fluids exhibit varying chemical properties, such as acidity, alkalinity, and corrosiveness, which can significantly affect the performance and longevity of pump materials. According to a recent report by the Fluid Handling Industry Association, material degradation accounts for nearly 30% of pump failures in industrial applications. Thus, it’s essential to opt for materials that resist corrosion and chemical attack while maintaining structural integrity over time.

Common pump materials include stainless steel, plastic, and special alloys, each offering unique advantages based on the fluid’s characteristics. For example, stainless steel is often favored for its strength and resistance to oxidation, making it suitable for both corrosive chemicals and high-temperature fluids. On the other hand, thermoplastics are lightweight and provide excellent resistance to a wide range of chemicals but may not withstand high pressures or temperatures. The compatibility of the pump materials with the specific fluid should be backed by data from manufacturers or chemical compatibility charts, which clearly outline how different materials interact with various substances. Such due diligence can greatly enhance operational efficiency and reduce maintenance costs in the long run.

10 Essential Tips for Choosing the Best Fluid Pumps for Your Project - Evaluating Pump Materials for Compatibility with Fluids

| Fluid Type | Pump Material | Compatibility | Temperature Range (°C) | Pressure Rating (psi) |

|---|---|---|---|---|

| Water | Stainless Steel | Compatible | -10 to 80 | 150 |

| Acid | Polypropylene | Compatible | 5 to 60 | 100 |

| Oil | Aluminum | Compatible | -20 to 70 | 250 |

| Saltwater | Titanium | Compatible | 0 to 50 | 200 |

| Biodiesel | Cast Iron | Compatible | 10 to 60 | 150 |

| Chemicals | PVC | Compatible | 5 to 40 | 100 |

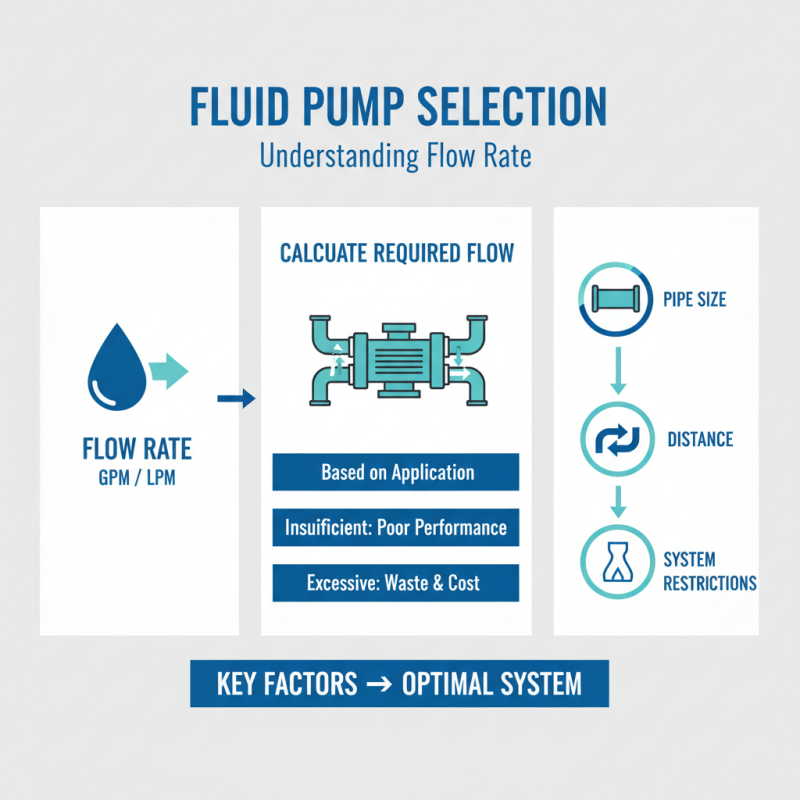

Assessing Flow Rate and Pressure Requirements for Your Application

When selecting the best fluid pumps for your project, understanding the flow rate and pressure requirements is crucial. The flow rate, typically measured in gallons per minute (GPM) or liters per minute (LPM), indicates how much fluid the pump can move within a specified time frame. It’s essential to calculate the required flow rate based on the intended application, as an insufficient flow rate can lead to inadequate system performance, while an excessive flow rate may result in waste and increased operational costs. To determine the right flow rate, consider factors such as the size of the pipes, the distance the fluid must travel, and any potential restrictions within the system that could impact movement.

Pressure requirements are equally important and involve understanding the pump's ability to overcome resistance in the system. Measured in psi (pounds per square inch) or bar, pressure dictates how effectively the pump can deliver fluid against gravitational forces and friction losses. When assessing pressure needs, evaluate the vertical lift required, the type of fluid being pumped, and any changes in elevation within the system. Collaborating these calculations with the desired flow rate will help to ensure optimal pump selection, enabling efficient and reliable operation for your specific application. Balancing these two critical parameters—flow rate and pressure—will ultimately enhance performance and longevity of the fluid handling system.

Considering Energy Efficiency and Operating Costs of Fluid Pumps

When selecting fluid pumps for your project, energy efficiency and operating costs should be at the forefront of your decisions. Energy-efficient pumps not only reduce the environmental impact but also translate into substantial financial savings over time. By leveraging technologies that minimize energy consumption, you can enhance the overall sustainability of your operations. Look for pumps that incorporate features such as variable speed drives, which allow for better control over flow rates while optimizing energy use.

In addition to energy efficiency, it's vital to consider the total operating costs associated with the pumps. This includes not just the initial purchase price but also maintenance, repair, and utility costs throughout the pump's lifespan. Pumps designed for lower wear and tear typically have reduced maintenance requirements, which can lead to lower long-term expenses. Furthermore, evaluating the pump's efficiency curve and understanding its performance under various load conditions can also help predict operational costs more accurately, ensuring that you choose a pump that not only fits your project's needs but also aligns with your budget constraints.

Energy Efficiency and Operating Costs of Fluid Pumps

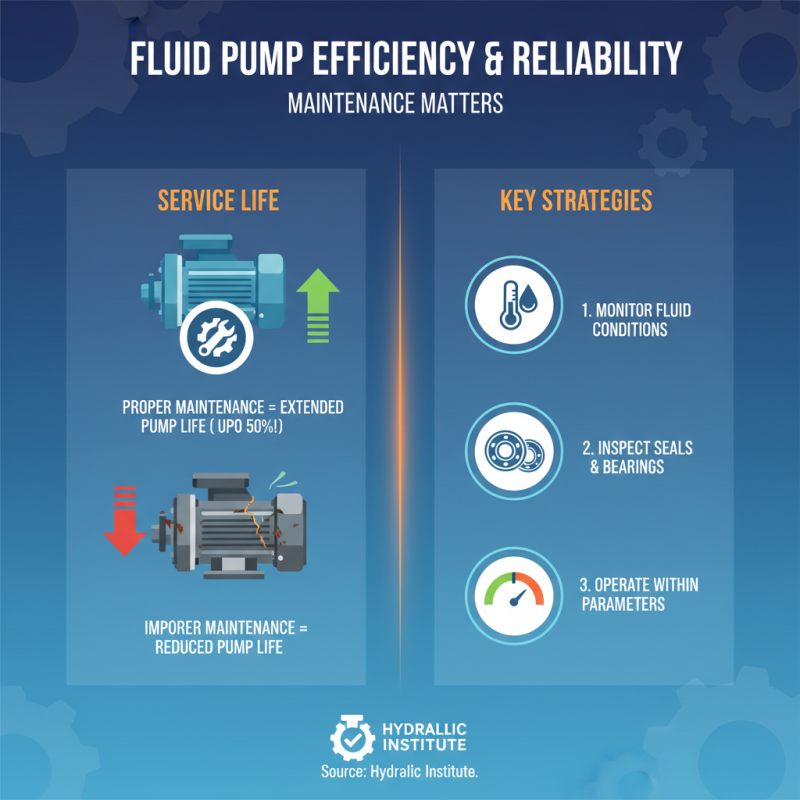

Examining Maintenance Needs and Service Life of Pump Options

When selecting fluid pumps for your project, understanding maintenance needs and service life is crucial for ensuring long-term efficiency and reliability. According to the Hydraulic Institute, improper maintenance can reduce pump life by up to 50%. Regular inspections and servicing not only extend the lifespan of the pump but also optimize its operational efficiency. A proactive maintenance strategy includes monitoring fluid conditions, inspecting seals and bearings, and ensuring that the pump operates within its designed parameters.

One essential tip when choosing fluid pumps is to consider the expected service life and the associated maintenance requirements. For instance, a pump designed for heavy-duty applications may require less frequent maintenance compared to those used in lighter applications. Additionally, employing predictive maintenance techniques, such as vibration analysis and thermal imaging, can help you anticipate potential failures before they happen, thus ensuring smoother operations.

Furthermore, it's important to evaluate the total cost of ownership (TCO) of the pump, which includes maintenance over its service life. A study by the American Society of Mechanical Engineers emphasizes that while initial costs are vital, the TCO can ultimately determine the pump's value. By choosing pumps with readily available spare parts and service support, project owners can minimize downtime and maintain efficient operations while ensuring that they get the most out of their investment.

Related Posts

-

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

Harnessing Industry Growth Through Motor Pumps at the 138th Canton Fair 2025

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.