10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

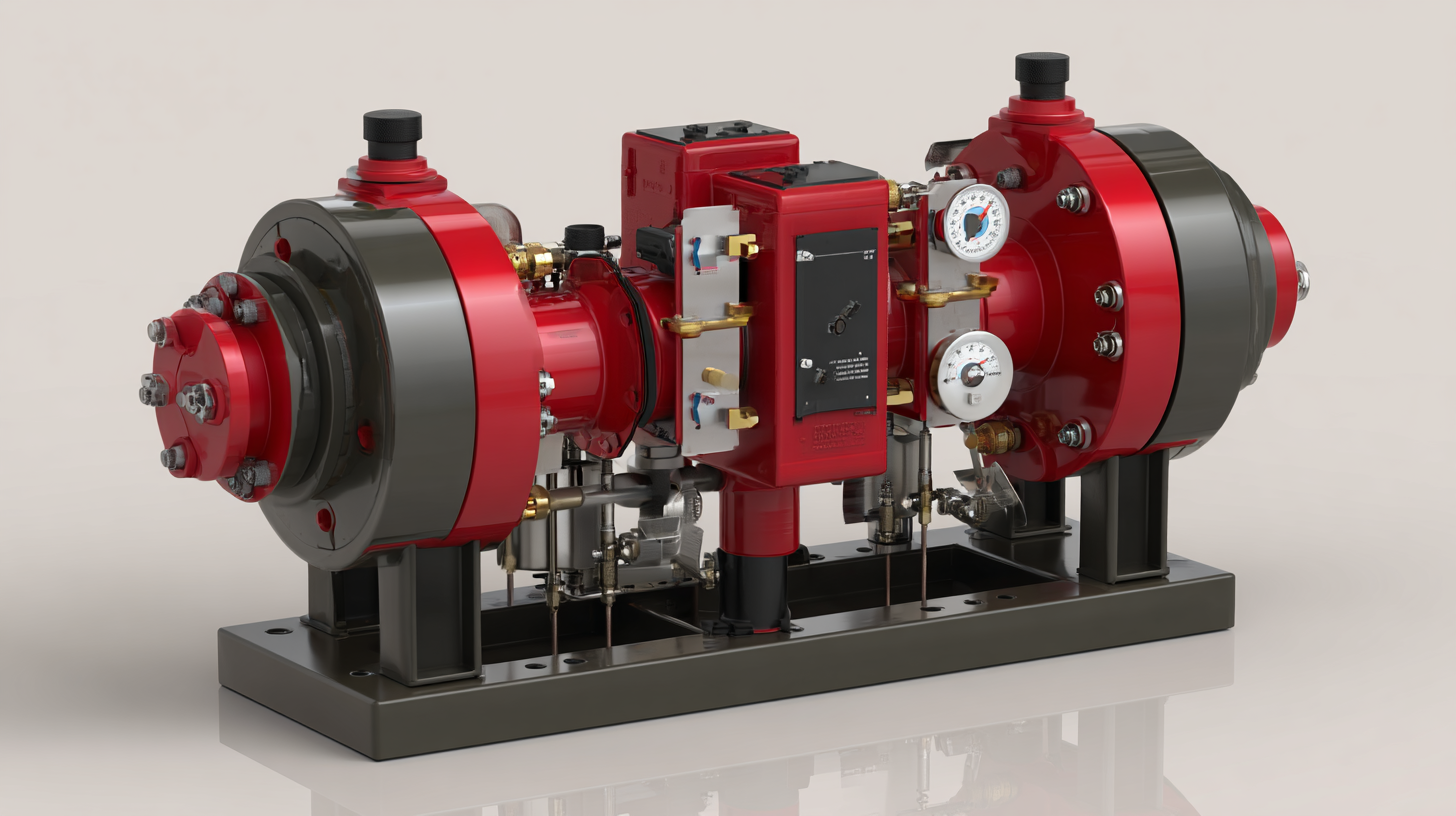

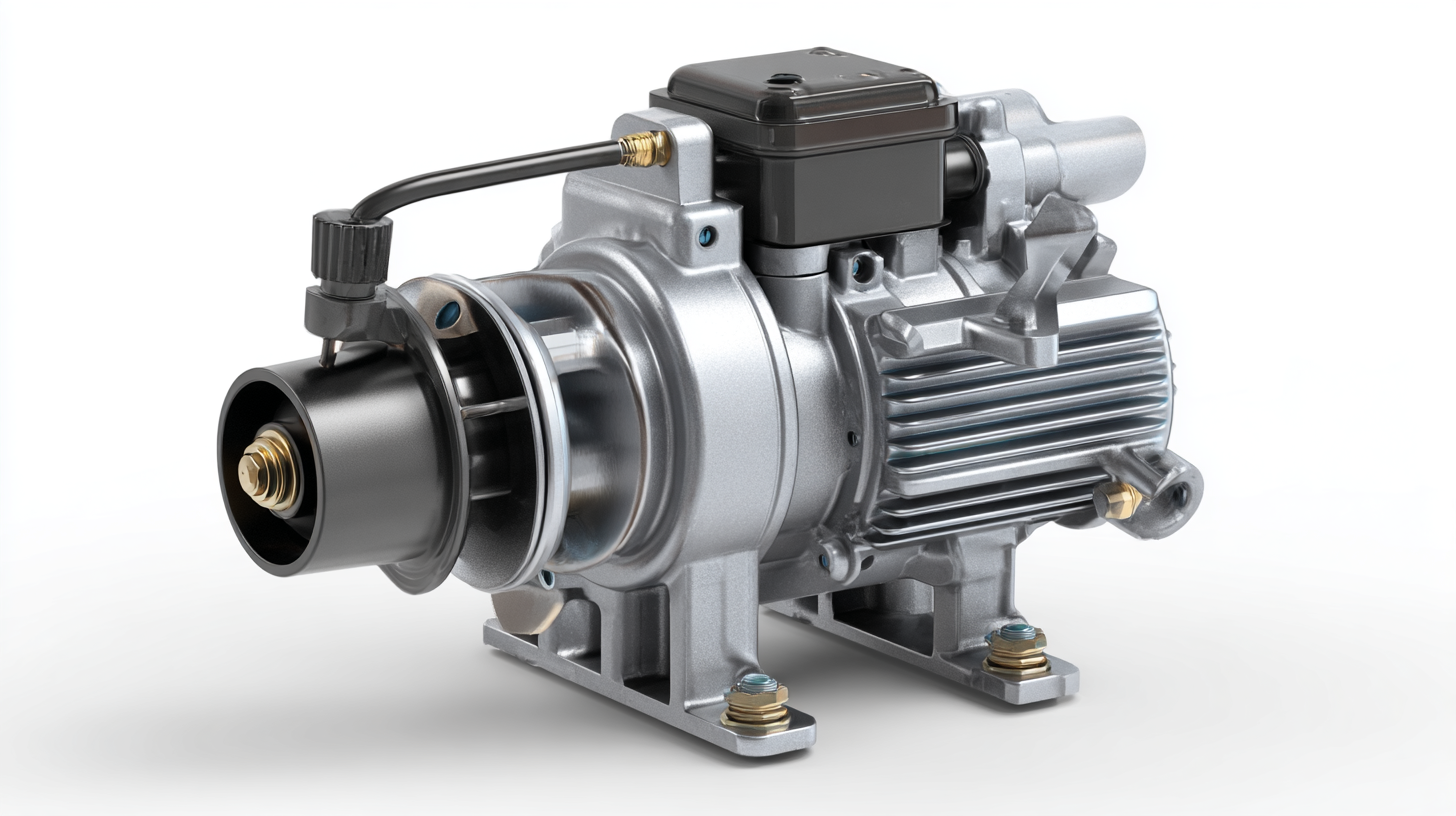

In today's dynamic industrial landscape, the demand for efficient fluid handling solutions is surging, with the global diaphragm pump market projected to reach approximately $5.9 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.8% (MarketsandMarkets). As businesses strive for enhanced operational performance, selecting the right equipment becomes crucial, and electric diaphragm pumps stand out as a versatile choice for various applications. These pumps are recognized for their ability to handle corrosive fluids, solids, and abrasive materials, making them indispensable in industries ranging from chemical processing to food production. However, with numerous options available, understanding the key factors that contribute to the optimal pump selection is essential. In this blog, we will explore 10 essential tips for choosing the right electric diaphragm pump for your business, ensuring you make an informed decision that boosts efficiency and meets your operational needs.

Key Factors to Consider When Selecting Electric Diaphragm Pumps for Industrial Applications

When selecting electric diaphragm pumps for industrial applications, several key factors come into play to ensure optimal performance and longevity. First and foremost, understanding the fluid characteristics—such as viscosity, temperature, and chemical compatibility—is crucial. Different diaphragm materials are suited for different applications, so choosing the right one can prevent operational issues and enhance pump durability. For example, certain diaphragms are designed to handle corrosive fluids, while others are better suited for thick slurries.

When selecting electric diaphragm pumps for industrial applications, several key factors come into play to ensure optimal performance and longevity. First and foremost, understanding the fluid characteristics—such as viscosity, temperature, and chemical compatibility—is crucial. Different diaphragm materials are suited for different applications, so choosing the right one can prevent operational issues and enhance pump durability. For example, certain diaphragms are designed to handle corrosive fluids, while others are better suited for thick slurries.

Another important consideration is the flow rate and pressure requirements of your specific application. Evaluating the pump’s specifications against your system's demands will help determine if a particular model is suitable. Additionally, consider the pump's ability to handle dry running scenarios, which can be important in many industrial settings. The energy efficiency of the pump should not be overlooked either; opting for a model with high efficiency can lead to significant cost savings in energy consumption over time. Ultimately, a thorough assessment of these factors will lead to a more informed choice, ensuring that the selected electric diaphragm pump meets the operational needs of your business effectively.

Understanding Flow Rate Requirements: How to Match Pump Capacity to Your Business Needs

When selecting an electric diaphragm pump for your business, understanding flow rate requirements is crucial. Different applications demand varying flow capacities, so it’s essential to assess the specific needs of your operations. Begin by calculating the total volume of fluid you need to transfer per hour. This will guide you in choosing a pump that meets your production demands efficiently.

One essential tip is to consider the viscosity of the fluid being pumped. Thicker fluids require more power and might necessitate a pump with a higher flow rate capability. Additionally, it's important to think about the operating conditions, such as temperature and pressure, as they can influence the pump's performance. Regular maintenance and monitoring of pump efficiency can help you ensure that the selected pump meets your flow requirements over time.

Lastly, don’t overlook the importance of flexibility in pump design. If your business needs may change, choosing a diaphragm pump with adjustable flow settings can be beneficial. This adaptability ensures that your investment remains valuable as your operational needs evolve, helping you avoid potential disruptions in your workflow.

Comparative Analysis of Materials: Selecting the Right Diaphragm for Chemical Compatibility

When selecting an electric diaphragm pump for your chemical operations, the choice of diaphragm material is crucial for ensuring compatibility with the fluids being handled. According to a report by the Chemical Engineering Journal, over 70% of diaphragm failures in industrial applications arise from chemical incompatibility. This highlights the need for a well-informed selection process. Common materials such as PTFE (Teflon), EPDM, and Nitrile each possess unique properties that make them suitable for different chemical environments. For instance, PTFE is renowned for its exceptional chemical resistance, suitable for aggressive acids and bases, whereas EPDM can handle aqueous solutions but is less effective against hydrocarbons.

Further emphasizing material selection, a study published in the Journal of Applied Polymer Science found that using incompatible diaphragm materials can lead to reduced operational efficiency and increased maintenance costs, averaging up to 15% of total operational expenses over time. Therefore, understanding the chemical composition of the fluids in your application is essential. By leveraging industry insights and reports, businesses can optimize their diaphragm selection process to ensure longevity and reliability in their pumping systems, ultimately enhancing productivity and reducing downtime.

Evaluating Pump Efficiency: Industry Standards and Their Impact on Operational Costs

When selecting an electric diaphragm pump for your business, evaluating its efficiency is paramount. Industry standards serve as a benchmark to gauge the performance of different models, providing crucial insights into their operational viability. These standards typically focus on flow rate, pressure capabilities, and energy consumption, giving potential buyers a clearer understanding of how a pump will perform in real-world situations. By adhering to these metrics, businesses can avoid costly mistakes that arise from subpar equipment.

Operational costs are significantly influenced by pump efficiency. A more efficient pump not only consumes less energy but also requires less maintenance, which translates into reduced overhead. Furthermore, understanding the correlation between pump efficiency and chemical compatibility is vital; it ensures that the chosen pump maintains its efficiency across various fluids, thus prolonging its lifespan and reliability. In environments with fluctuating demands, selecting a pump that meets or exceeds industry standards can ultimately embody a strategic investment, impacting both profitability and operational effectiveness.

Maintenance and Support: Ensuring Longevity and Reliability in Your Pumping System

When selecting an electric diaphragm pump for your business, maintenance and support play critical roles in ensuring both longevity and reliability. According to a report by the Hydraulic Institute, proper maintenance can enhance pump life expectancy by up to 30%. Regular inspections and timely interventions can prevent minor issues from escalating into costly repairs or operational downtime. Businesses must prioritize a maintenance schedule that includes routine checks of diaphragms, seals, and valves, which are vital components that can wear down over time.

Furthermore, choosing a supplier that offers comprehensive support services is essential. Research from the Pump Industry Analyst indicates that 60% of businesses experience pumping failures due to lack of technical support or inadequate service agreements. Reliable supplier support not only aids in troubleshooting but also provides access to updated materials and replacement parts, ensuring uninterrupted operations. By focusing on these aspects, businesses can significantly improve their pumping system's reliability and overall efficiency while minimizing operational risks.

Related Posts

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

-

Evaluating Cost-Effectiveness: A Comparative Analysis of Pump Rentals vs. Purchasing Equipment

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

What is the Functionality Behind Liquid Pumps in Modern Industries

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.