2025 How to Choose the Right Liquid Pump for Your Industrial Needs

In the dynamic landscape of industrial operations, selecting the right liquid pump is critical to ensuring efficiency and reliability in fluid management systems. According to a recent market analysis report by Smith & Associates, the global liquid pump market is projected to reach $70 billion by 2025, driven by increasing demand from sectors such as oil and gas, chemicals, and food and beverage. As industries continue to evolve, understanding the different types of liquid pumps and their specific applications becomes imperative for ensuring optimal performance.

Expert insights highlight the complexities of this selection process. Dr. Olivia Jacobs, a renowned authority in pump engineering, emphasizes the importance of alignment with operational needs: “Choosing the right liquid pump involves not only considering the fluid characteristics but also understanding the system dynamics and operational environment.” With various types of pumps available, including centrifugal, positive displacement, and submersible pumps, each type presents unique advantages and challenges. This guide aims to provide valuable insights into the selection criteria for liquid pumps, ensuring that industrial businesses are equipped to make informed decisions for their specific operational requirements.

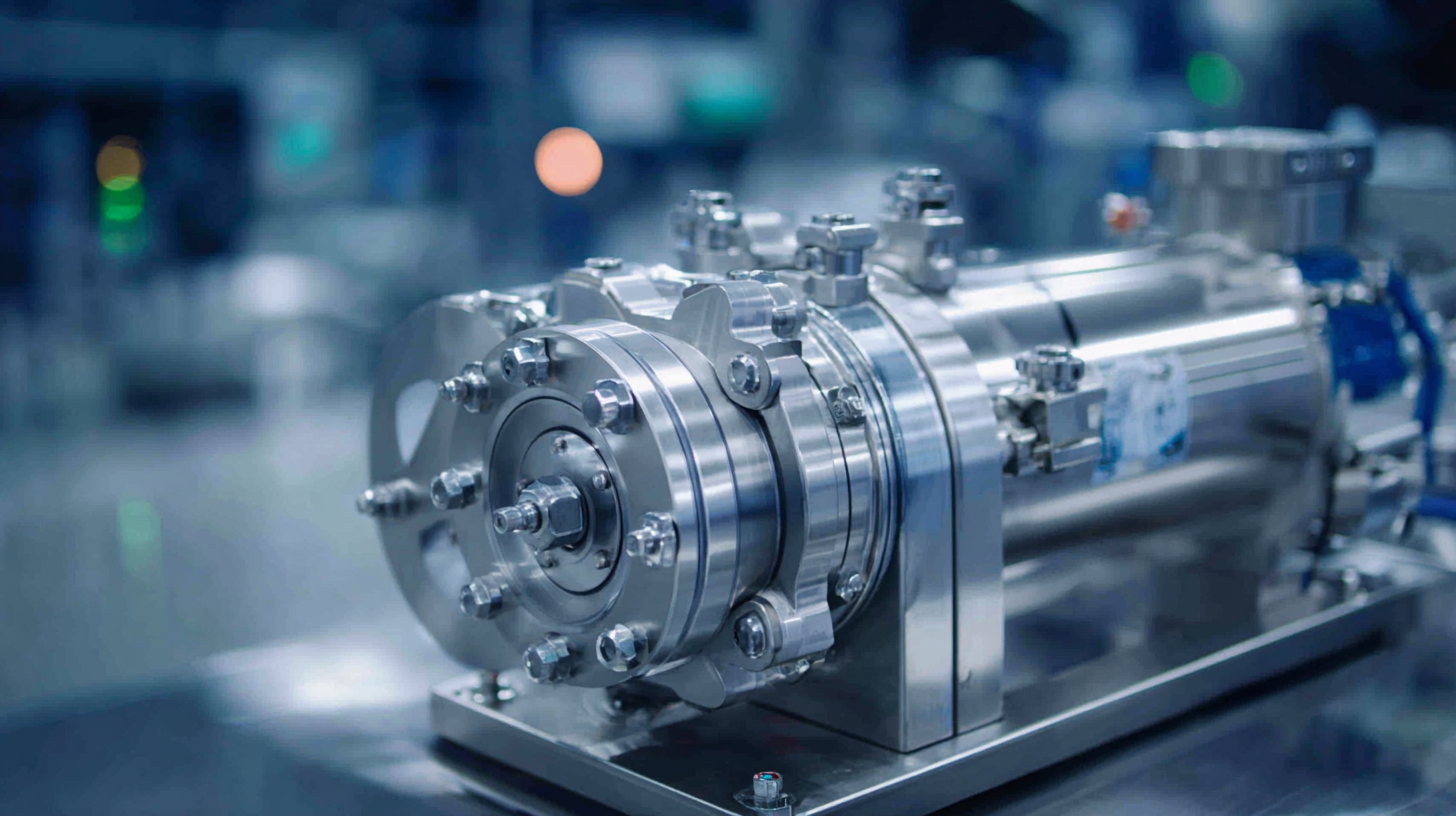

Understanding the Different Types of Liquid Pumps: A Comprehensive Overview

When selecting a liquid pump for industrial applications, it's essential to understand the different types of pumps available. The two primary categories of liquid pumps are positive displacement pumps and centrifugal pumps. Positive displacement pumps move liquid by trapping a fixed amount of it and forcing it into the discharge pipe, making them ideal for applications requiring high pressure and viscosity handling. In contrast, centrifugal pumps utilize rotational energy to move liquids, excelling in high-flow applications with lower viscosity.

**Tips:** When choosing a pump, consider the properties of the liquid, including viscosity, temperature, and corrosiveness. This ensures compatibility and optimal performance. Additionally, evaluate the required flow rate and pressure range to find the most suitable pump type for your needs.

Another crucial factor is the pump's energy efficiency and maintenance requirements. Some pumps, such as magnetic drive pumps, offer reduced energy consumption and minimal maintenance. Conversely, certain positive displacement pumps may require more frequent servicing due to their complex mechanisms. Reviewing these aspects will help you select a pump that not only meets your immediate needs but also contributes to long-term operational efficiency.

2025 How to Choose the Right Liquid Pump for Your Industrial Needs

| Pump Type | Best Use Cases | Flow Rate (GPM) | Pressure Range (psi) | Efficiency | Maintenance Level |

|---|---|---|---|---|---|

| Centrifugal Pump | Water Supply, Chemical Transfer | 20-400 | 10-100 | High | Low |

| Positive Displacement Pump | Viscous Fluids, High Precision | 5-200 | 50-200 | Medium | Medium |

| Diaphragm Pump | Chemical Processing, Food & Beverage | 2-120 | 15-80 | High | Low |

| Gear Pump | Oil, Fuel Transfer | 1-100 | 30-150 | Medium | Medium |

| Submersible Pump | Dewatering, Wastewater Management | 5-500 | 10-50 | High | Low |

Key Factors Influencing Liquid Pump Selection in Industrial Applications

When selecting the right liquid pump for industrial applications, several key factors must be considered to ensure optimal efficiency and effectiveness. Firstly, the type of liquid being pumped plays a crucial role. Different liquids have varying viscosities, temperatures, and chemical compositions that can influence pump performance. For instance, viscous liquids may require a pump with a higher torque capacity, while corrosive fluids may necessitate materials that are resistant to chemical degradation.

Another significant factor is the required flow rate and pressure. It is essential to determine the specific flow rate needed for the particular application, as pumps are typically designed to operate within certain parameters. Additionally, understanding the total dynamic head (TDH) – which combines the vertical lift and friction losses in the system – is vital for selecting a pump that can deliver the necessary pressure. Accessibility for maintenance and energy efficiency are also pivotal considerations that can impact both operational costs and longevity of the pump selected. By thoroughly assessing these factors, industries can choose the most suitable liquid pump tailored to their unique requirements.

Evaluating Pump Efficiency: Energy Consumption and Cost Analysis

When selecting the appropriate liquid pump for industrial applications, evaluating pump efficiency becomes crucial, particularly in terms of energy consumption and cost analysis. According to the AGA Energy Analysis, high-efficiency equipment can significantly reduce annual energy costs, an essential consideration for industries aiming to optimize operational expenses. Leveraging tools like the Pumping System Assessment Tool (PSAT) can aid industrial users in assessing the efficiency of their pumping systems, providing valuable insights that contribute to minimizing energy waste.

In addition, recent studies highlight the importance of understanding the Total Cost of Ownership of pumping systems. An integrated techno-economic analysis has shown that efficient water and energy management, especially in arid climates, is vital for reducing energy demands that often accompany water management challenges. By closely analyzing the energy efficiency of pumps alongside their operational data, industries can adopt strategies that not only enhance performance but also align with sustainability goals, especially given the increasing pressures for energy efficiency highlighted in government initiatives.

The Role of Fluid Properties in Choosing the Right Pump Type

When selecting the appropriate liquid pump for industrial applications, understanding the properties of the fluid being handled is crucial. Key fluid properties such as viscosity, density, temperature, and chemical compatibility directly influence the performance and longevity of the pump. For instance, high-viscosity fluids might require positive displacement pumps, while low-viscosity fluids are often effectively managed by centrifugal pumps. Additionally, the presence of particulates or abrasive substances can dictate the choice of material for the pump components to ensure durability.

Temperature variations also play a significant role in the operational capacity of pumps. Pumps designed for high-temperature fluids need specific materials and seals that can withstand thermal expansion and corrosion. Moreover, the chemical nature of the liquid—whether it is corrosive, neutral, or hazardous—will heavily impact the selection process, guiding users toward pumps made from compatible materials that can handle such conditions without failure. By thoroughly analyzing these fluid properties, industries can make informed decisions, ensuring efficiency and reliability in their liquid transfer operations.

Choosing the Right Liquid Pump for Industrial Needs

This bar chart displays the efficiency of different pump types based on the fluid properties. Understanding how each fluid type influences pump performance is crucial for selecting the appropriate pump for industrial applications.

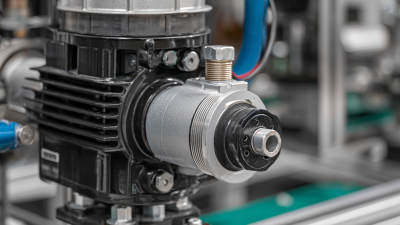

Identifying Maintenance Requirements for Long-Term Pump Performance

When selecting a liquid pump for industrial applications, understanding maintenance requirements is crucial for ensuring long-term performance. Regular upkeep not only extends the pump's lifespan but also improves operational efficiency. Start by reviewing the manufacturer's guidelines, which typically outline essential maintenance tasks, including lubrication schedules, seal inspections, and motor checks.

Tips: Implement a routine maintenance schedule that aligns with your operational demands. Keeping a comprehensive log of maintenance activities can help you identify patterns and anticipate potential failures.

Additionally, training your team to recognize early signs of wear can make a significant difference. Employees should be aware of unusual noises, vibrations, or changes in fluid output. These indicators often serve as early warning signs that require immediate attention, preventing costly downtime and repairs.

Tips: Consider using predictive maintenance tools that leverage IoT technology to monitor pump performance in real-time. This proactive approach allows for timely interventions and optimizes asset management.

Related Posts

-

Innovative Liquid Pumps: Transforming Industrial Efficiency and Performance

-

Unlocking the Secrets of Liquid Pumps and Their Impact on Modern Technology

-

Harnessing Industry Growth Through Motor Pumps at the 138th Canton Fair 2025

-

How to Maximize Efficiency in Your Solar Pump System with Latest Technology Innovations

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

What is the Functionality Behind Liquid Pumps in Modern Industries

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.