How to Choose the Right Injection Pumps for Your Needs

Choosing the right injection pumps is crucial for various industries. The global market for injection pumps reached $8.5 billion in 2022 and is projected to grow significantly. This highlights their importance in sectors such as pharmaceuticals, agriculture, and petrochemicals.

Selecting an injection pump involves analyzing specific needs. Different applications require distinct pump types. For instance, a metering pump may be ideal for agricultural use, while a diaphragm pump suits chemical applications. Moreover, considering factors like flow rate, pressure, and fluid compatibility is essential.

Mistakes in selection can lead to inefficiencies. It's vital to reflect on past decisions. Reviewing performance data from industry reports can help refine choices. Attention to detail is necessary to avoid costly errors in procurement.

Understanding the Different Types of Injection Pumps Available

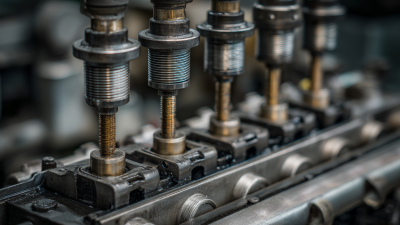

When selecting the right injection pumps, it’s crucial to understand the types available. The most common types are gear pumps, diaphragm pumps, and screw pumps. Each type serves different purposes. Gear pumps are great for high viscosity fluids, while diaphragm pumps work well with corrosive substances. Screw pumps provide a smooth flow, suitable for various liquids.

Tips: Identify your fluid type before making a choice. This ensures compatibility and efficiency. Also, consider the flow rate you need. Different applications require different rates, so matching these values is key.

Another important factor is the pressure rating. Some pumps can handle high pressures, while others cannot. Make sure to check this to avoid malfunctions. Sometimes, you may need to reevaluate your choice based on usage. A pump that's perfect for one situation may fail in another. Always assess your specific needs first.

Key Factors to Consider When Selecting an Injection Pump

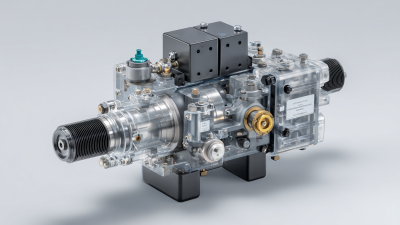

Choosing the right injection pump requires thoughtful consideration. Key factors, such as flow rate, viscosity, and application type can significantly impact your decision. According to industry reports, the global injection pump market is projected to reach USD 4.63 billion by 2026, growing at a CAGR of 6.7%. This reflects the rising importance of selecting appropriate pump systems in various sectors.

The flow rate is vital. Each application has specific demands. For example, low flow rates work well for precise dosing in pharmaceuticals. However, high-capacity rates are crucial in agriculture. Consider your needs carefully. Also, a pump that handles a specific viscosity may falter with different substances. Understanding these parameters will lead to better outcomes.

**Tips:**

Always evaluate the total cost of ownership. Lower-priced pumps may not offer durability. Maintenance costs can add up. Consider your requirements. Ensure compatibility with your fluid types. Testing a pump’s performance through trial can help identify potential issues early on.

Reflect on power requirements too. A pump with insufficient energy can lead to operational inefficiencies. Balancing performance and efficiency is essential for long-term success.

Injection Pumps Performance Comparison

Assessing Your Specific Application Requirements for Injection Pumps

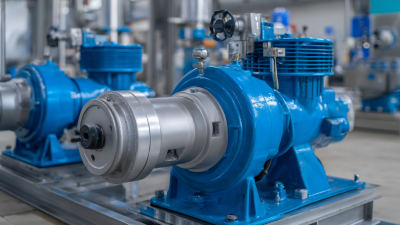

When choosing injection pumps, evaluating specific application requirements is crucial. Each application has unique demands, whether in agriculture, chemical processing, or water treatment. The American Society of Mechanical Engineers reported that selecting appropriate pump types can affect efficiency by up to 30%. This metric highlights the importance of careful consideration.

For example, the required flow rate and pressure significantly impact your choice. High-viscosity fluids often need specialized pumps, like gear or diaphragm types. A study by the Hydraulic Institute found that ignoring viscosity can lead to significant performance loss. Cost also plays a role. Sometimes, a lower-priced option may result in higher operating costs due to inefficiencies.

Clarity about the fluid's characteristics is vital. Understanding the corrosiveness, temperature, and particulate matter helps eliminate unsuitable options. According to the Pump Industry Analyst, about 25% of pump failures stem from inadequate material selection. Many users overlook the importance of these details, leading to unforeseen issues. Each application tells a unique story, and your pump choice affects that narrative.

Evaluating the Performance and Efficiency of Injection Pumps

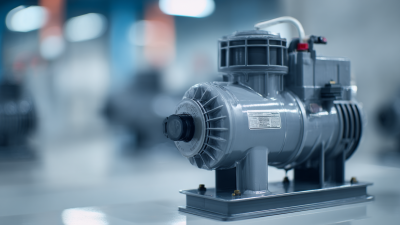

When selecting injection pumps, performance and efficiency are key. These factors can greatly affect the overall application. Efficiency refers to how effectively a pump converts energy. Higher efficiency usually means lower operational costs. However, selecting a pump that is only focused on efficiency can lead to complications. Sometimes, pump size and capacity are overlooked.

Assessing performance involves multiple aspects. Flow rate, pressure capacity, and durability come into play. A pump might perform well at a specific flow rate but fail under varying conditions. This inconsistency is often a source of frustration. Users must consider varying operational scenarios when evaluating performance metrics.

Users should reflect on real-world applications as well. The right pump for one setting might not be ideal for another. Sometimes, the most efficient pump can struggle in unique environments. Balancing performance and efficiency requires careful thought. It is essential to prioritize the specific needs of your system. Consider not just the current situation but future demands as well. This helps in avoiding potential pitfalls.

Budgeting and Cost Considerations for Injection Pump Purchases

When budgeting for an injection pump, start by determining your specific needs. Consider the application and the required capacity. Costs can vary widely based on features and specifications. Smaller, simpler pumps may be less expensive, but they might lack the performance required for certain tasks.

Think about additional costs as well. Installation and maintenance can add to the overall budget. Skilled labor may be necessary for setup. Regular maintenance must not be overlooked, as this prevents costly repairs down the road.

You might find it helpful to evaluate different suppliers. Comparison shopping can help identify the best value for your needs. However, low prices can sometimes mean low quality. It's essential to weigh the cost against reliability and lifespan. Making a hasty decision may lead to regrets later on. Proper planning can save you money and headaches in the future.

Related Posts

-

How to Optimize Your Injection Pumps for Maximum Efficiency and Performance

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

2025 Top Chemical Injection Pumps: The Ultimate Guide to Choosing the Best Options

-

Best Electric Pumps for Your Home Needs in 2023

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

How to Choose the Right Electric Pumps for Your Business Needs

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.