The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

In today's rapidly evolving industrial landscape, the selection of the right fluid pumps is crucial for operational efficiency and productivity. According to a recent market analysis from Grand View Research, the global fluid pumps market is expected to reach USD 73.11 billion by 2025, driven by increasing demand across various sectors including oil and gas, water and wastewater management, and chemicals.

With an array of pumps available - from centrifugal to positive displacement - choosing the appropriate type can significantly impact fluid transfer processes and equipment longevity. This guide aims to empower professionals in making informed decisions by exploring key factors such as pump types, applications, maintenance requirements, and performance metrics, ensuring that your industrial operations run smoothly and efficiently.

Key Considerations for Selecting Suitable Fluid Pumps for Industrial Applications

When selecting the right fluid pumps for industrial applications, understanding your specific needs is crucial. Key factors to consider include the type of fluid being pumped, its viscosity, temperature, and corrosiveness. Different materials and designs of fluid pumps cater to various fluids, so it’s vital to match the pump construction with the characteristics of the fluid. For instance, corrosive fluids may require pumps made from special alloys or plastics to prevent degradation.

Additionally, consider the required flow rate and pressure for your application. Pumps are designed for specific capacities, and selecting one that can handle your operational demands without strain is essential for efficiency and longevity. Energy consumption is another important factor; choosing a pump with optimized energy use can lead to significant cost savings in the long run. Lastly, maintenance and reliability play a pivotal role in your decision-making process. Opt for pumps that are easy to maintain and come with a solid warranty, ensuring that your industrial operation runs smoothly without unexpected downtimes.

Top 5 Types of Fluid Pumps and Their Specific Industrial Uses

Fluid pumps are essential components in various industrial applications, with different types tailored to specific needs. According to the Global Market Insights report, the fluid pump market is projected to surpass $35 billion by 2027, highlighting their critical role in numerous sectors. Here, we discuss the top five types of fluid pumps and their specific industrial uses.

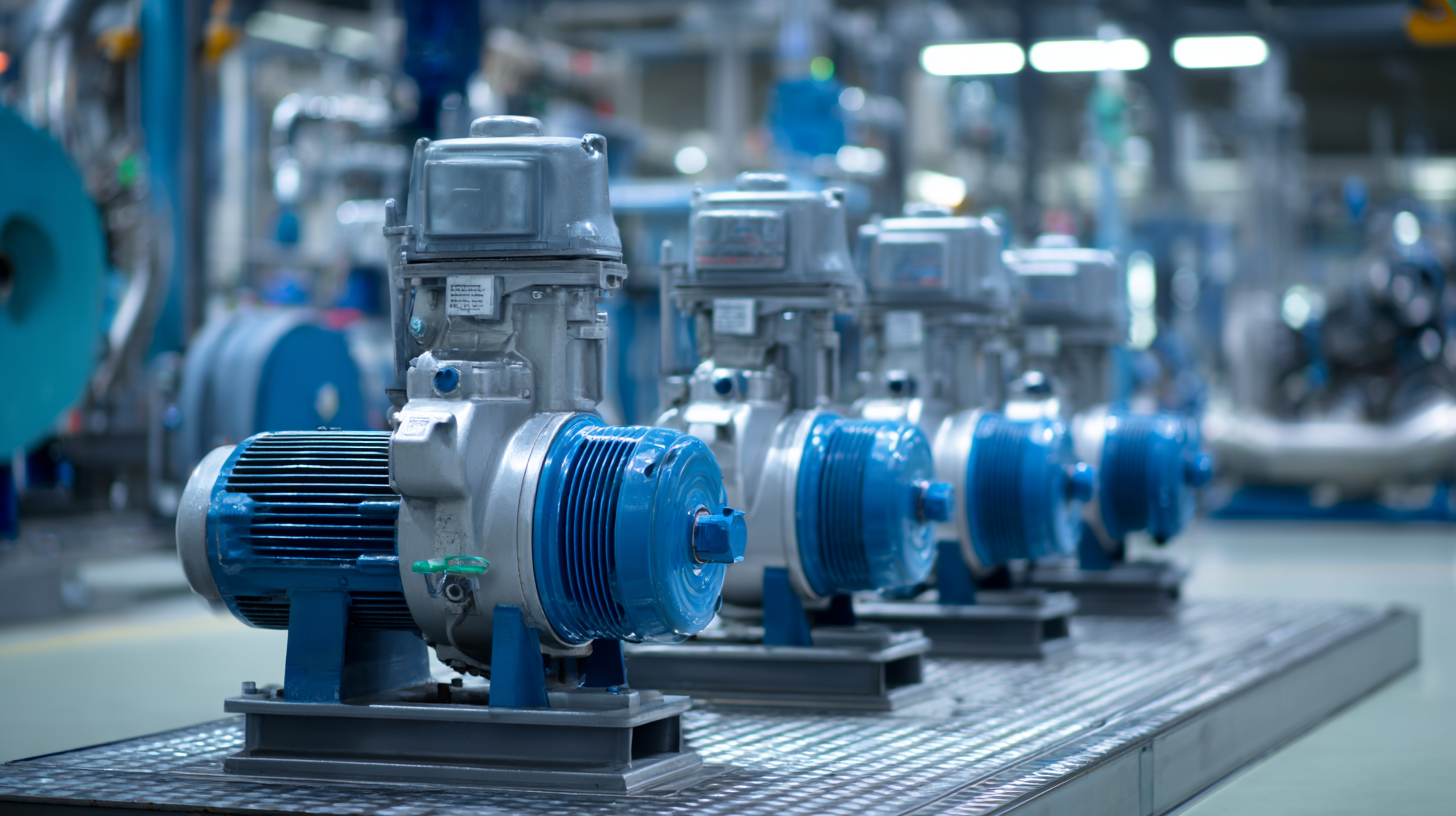

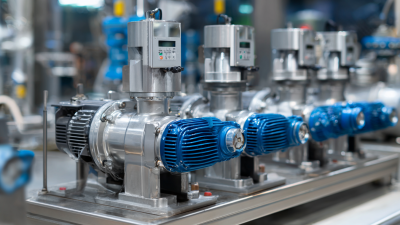

Firstly, centrifugal pumps are widely used in chemical processing and water treatment due to their efficiency in moving large volumes of fluids. They can handle both clean and slightly dirty liquids, making them suitable for industries like pharmaceuticals, where maintaining fluid purity is paramount. Secondly, positive displacement pumps are noted for their ability to carefully control flow rates, making them ideal for applications involving viscous fluids, such as oil and grease in manufacturing processes.

Another key type is diaphragm pumps, recognized for their versatility and ability to handle corrosive and abrasive liquids, commonly used in mining and wastewater treatment. Peristaltic pumps, on the other hand, excel in transferring shear-sensitive fluids, crucial for industries such as food and beverage where product integrity is vital. Lastly, screw pumps are gaining traction in oil and gas extraction due to their ability to move high-viscosity fluids effectively. Understanding these pump types and their operational capacities can significantly enhance efficiency and productivity in industrial settings.

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

Essential Performance Metrics to Evaluate When Choosing Fluid Pumps

When selecting fluid pumps for industrial applications, understanding essential performance metrics is crucial to making an informed decision. Among the primary factors to evaluate are flow rate, pressure, and efficiency. The flow rate indicates how much fluid can be transported within a given time, affecting operational productivity. Pressure, on the other hand, determines how effectively the pump can move fluid, especially in systems requiring a high elevation or long distances.

When selecting fluid pumps for industrial applications, understanding essential performance metrics is crucial to making an informed decision. Among the primary factors to evaluate are flow rate, pressure, and efficiency. The flow rate indicates how much fluid can be transported within a given time, affecting operational productivity. Pressure, on the other hand, determines how effectively the pump can move fluid, especially in systems requiring a high elevation or long distances.

Tips: Always cross-reference the required flow rate with the pump specifications to ensure compatibility with your system demands. Additionally, consider the maximum operating pressure of the pump to ensure it matches your operational requirements.

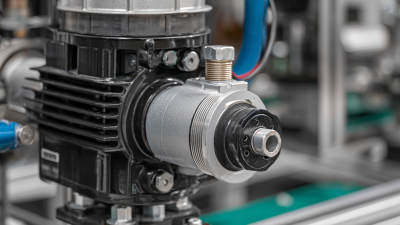

Another metric to consider is the pump’s compatibility with various fluid types. Different fluids possess unique characteristics, such as viscosity and corrosiveness, which can impact pump performance. Evaluating the materials used in pump construction can help avoid premature wear and malfunctions.

Tips: Conduct a thorough analysis of the fluids intended for use, taking into account temperature variations and chemical interactions, to select a pump that can endure harsh conditions. Always consult with manufacturers regarding specific applications to ensure optimum performance and longevity.

7 Common Mistakes to Avoid When Purchasing Fluid Pumps for Your Facility

When purchasing fluid pumps for industrial applications, avoiding common mistakes can significantly enhance the reliability and efficiency of your systems. One prevalent error is neglecting to evaluate the specific requirements of your application, including flow rate, pressure, and the type of fluid being handled. According to industry reports, improper pump selection can lead to a staggering 20% reduction in energy efficiency. Understanding the operational parameters ensures choosing a pump that can comfortably meet your demands.

Another critical mistake is overlooking regular maintenance protocols. Research indicates that about 25% of pump failures are attributed to inadequate upkeep. Establishing a proactive maintenance schedule not only extends the lifespan of your pumps but also minimizes unscheduled downtimes, ultimately preserving your facility's production capabilities. Additionally, be cautious of not consulting with experts or relying solely on vendor specifications. Engaging with professionals can yield valuable insights and help you avoid pitfalls that can lead to costly errors in pump procurement and operation.

How to Match Fluid Pump Specifications with Your System Requirements

When selecting fluid pumps for industrial applications, aligning the pump specifications with system requirements is crucial for optimal performance and efficiency. Industries can lose up to 30% of their energy costs due to improper pump selection, according to a report from the Hydraulic Institute. Understanding factors such as flow rate, pressure, viscosity, and chemical compatibility helps to avoid such inefficiencies. Taking the time to analyze these parameters ensures that the chosen pump can handle the specific medium and application demands.

**Tips:** Always refer to the manufacturer’s performance curves to verify pump capabilities under varying operating conditions. This data not only provides insight into the pump's efficiency but also highlights its limitations. Additionally, consider the total cost of ownership, which includes maintenance, energy consumption, and initial investment, as outlined in a study by the National Fluid Power Association.

When investigating pump options, pay attention to the material construction as certain fluids can cause corrosion or degradation. For example, a recent study revealed that using the wrong material can lead to equipment failure in over 40% of cases. Selecting pumps made from compatible materials can greatly enhance longevity and reliability in fluid transfer operations.

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

| Pump Type | Flow Rate (GPM) | Maximum Pressure (PSI) | Material Compatibility | Power Source |

|---|---|---|---|---|

| Centrifugal Pump | 10 - 500 | 50 - 300 | Water, Chemicals | Electric, Diesel |

| Positive Displacement Pump | 5 - 250 | 100 - 2000 | Viscous Fluids, Oil | Electric, Hydraulic |

| Diaphragm Pump | 1 - 100 | 30 - 150 | Chemicals, Sludges | Pneumatic, Electric |

| Gear Pump | 2 - 200 | 50 - 2000 | Oil, Fuel | Electric, Diesel |

| Progressing Cavity Pump | 5 - 250 | 50 - 500 | Slurries, Viscous Fluids | Electric, Hydraulic |

Related Posts

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

-

Liquid Pump Innovations and Industry Trends Highlighted at 2025 China Import and Export Fair

-

How to Maximize Efficiency in Your Solar Pump System with Latest Technology Innovations

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.