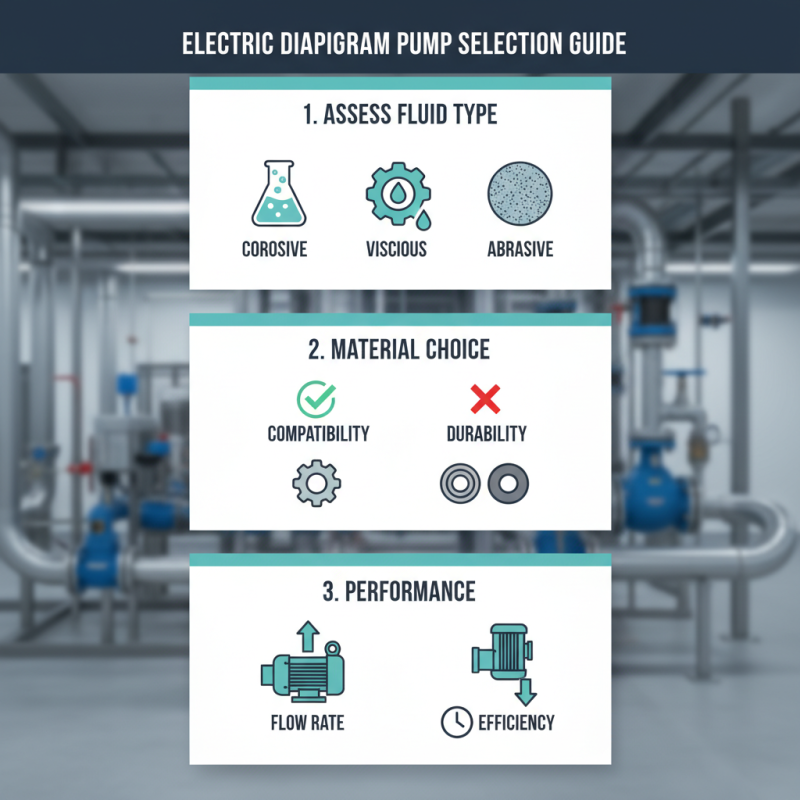

How to Choose the Right Electric Diaphragm Pump for Your Needs?

The choice of an electric diaphragm pump can significantly impact operational efficiency. According to a report by Global Market Insights, the electric diaphragm pump market is expected to grow at a CAGR of 6.5% by 2026. This growth is driven by surging demand in various industries, from chemical processing to food and beverage. An expert in the field, Dr. Lisa Carter, emphasizes, "Selecting the right pump is crucial for ensuring optimal performance and reliability."

With many options available, identifying the right electric diaphragm pump can be overwhelming. Factors such as flow rate, pressure, and material compatibility require careful consideration. Each application demands careful examination; a mismatch can lead to inefficiencies or premature equipment failure. Admittedly, navigating through technical specifications can sometimes feel daunting, leading to hasty decisions and regret later.

Moreover, understanding the nuances of different pump designs is essential. Not all electric diaphragm pumps perform equally under varied conditions. Some may excel in handling abrasive materials, while others may struggle. As Dr. Carter points out, "A well-informed choice can prevent costly downtime." Therefore, investing time in research and consultation is essential for success in this critical decision-making process.

Understanding the Basic Functionality of Electric Diaphragm Pumps

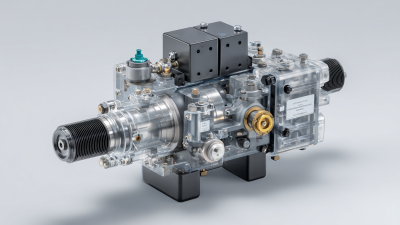

Electric diaphragm pumps are versatile tools widely used in various industries. They use a flexible diaphragm that creates a pumping action. This mechanism allows them to handle different fluids, from water to chemicals. The diaphragm's design minimizes leaks, making these pumps reliable. They can move a consistent flow of liquid while maintaining pressure.

Choosing the right pump requires understanding its functionality. Consider the fluid type and viscosity. Some fluids might cause wear or damage to certain materials. Operating conditions like temperature and pressure also matter. A pump that works well in one setting may fail in another. It's crucial to evaluate all factors before making a decision.

Electric diaphragm pumps can be energy-efficient. They often use less electricity than traditional pumps. However, not all pumps are created equal. Some may consume more power or have higher maintenance needs. Regular assessments of efficiency can lead to better choices. Reflecting on past experiences with pump performance is essential for future purchases.

Identifying Your Specific Pumping Requirements and Applications

When choosing an electric diaphragm pump, understanding your specific pumping needs is crucial. Different applications require different pump features. Identify the fluid type you will be handling. Is it corrosive, viscous, or abrasive? This information guides the selection of materials for your pump. It impacts durability and performance.

Tips: Consider the environmental conditions. Is high humidity or extreme temperatures a factor? Delve into the required flow rate and pressure. Insufficient flow can lead to inefficiencies.

Pumping requirements may vary widely between industries. A laboratory setup may need precise control, while an agricultural application might focus on high capacity. Each setting challenges the diaphragm pump differently. A thorough assessment can reveal unexpected needs. Review the maintenance requirements, as well. Regular upkeep is essential for longevity. Think about the energy efficiency of the pump, too. A more efficient pump saves on electricity costs in the long run.

Evaluating Key Features and Specifications of Diaphragm Pumps

Choosing the right electric diaphragm pump involves understanding key features and specifications. Not all pumps are created equal. Each application has unique requirements. Knowing these can help narrow your choices significantly.

One critical feature is flow rate. It determines how quickly the pump can move liquid. Make sure to match the pump’s flow rate with your project needs. Too low a rate can impede operations. Too high can waste energy.

Tips: Always consider the materials used in the pump. Compatibility with the liquid being pumped is crucial. For instance, corrosive liquids need resistant materials. Lastly, don’t overlook maintenance. Regular checks can prolong a pump’s life and efficiency.

Reflect on what you need. A pump may look perfect but may not fit your exact situation. Research and test different options. Each detail counts towards making an informed decision.

Comparing Different Brands and Models for Performance and Reliability

When choosing an electric diaphragm pump, it’s critical to compare various brands and models. Some pumps excel in specific applications, while others offer better versatility. Performance can fluctuate based on the pump's design and materials. Look for pumps made with durable materials for reliable long-term use. Assessing the maximum flow rate and pressure is vital. It directly impacts how well the pump meets your operational needs.

Reliability is another factor to consider. Some pumps may have excellent specifications but lack in real-world performance. User reviews can provide valuable insights. However, opinions may vary widely among users. Be cautious about taking every review at face value. Sometimes, a seemingly perfect pump can have hidden flaws that only become apparent after extended use.

Ultimately, testing different models could reveal unexpected strengths or weaknesses. Each pump's maintenance requirements can differ. Some may need frequent part replacements, while others might be more robust. Take the time to gather information. This process is crucial for making an informed decision. Balancing performance, reliability, and maintenance will serve you well in the long run.

Performance Comparison of Electric Diaphragm Pumps

Considering Cost, Maintenance, and Support Options for Your Pump Choice

When selecting the right electric diaphragm pump, considering cost, maintenance, and support is crucial. The global diaphragm pump market was valued at approximately $4 billion in 2020 and is expected to grow steadily. This growth highlights the importance of making an informed choice. Maintenance costs can significantly impact your budget. Regular service and potential repairs should be factored into the initial investment. Aim for pumps with robust warranties and accessible support options to reduce long-term expenses.

**Tip**: Analyze your operational demands closely. Understanding the specifics of your applications will help you avoid overspending on unnecessary features. Some pumps might offer excessive functionality that you may not need.

Support is another vital element. Reliable customer service can minimize downtime, which can be costly. Research companies that provide comprehensive technical support and maintenance plans. This could save you from handling unexpected issues alone.

**Tip**: Keep spare parts handy. Having essential components on-site can prevent extended interruptions in operation. It may seem like an added cost upfront, but this preparation can lead to significant savings over time. Reflect on your previous experiences with equipment failures; lessons learned can steer you away from making the same mistakes again.

Related Posts

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

Top 10 Electric Pumps for Your Home: Reviews and Buying Guide 2023

-

Top 10 Electric Pumps for Efficient Water Transfer and Usage

-

How to Choose the Best Diaphragm Pump for Your Needs: A Comprehensive Guide

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.