How to Choose the Right Chemical Diaphragm Pump for Your Needs

When selecting the ideal chemical diaphragm pump for a specific application, the choices can be overwhelming. According to Dr. Emily Carter, a leading expert in fluid dynamics and pump technology, "Choosing the right chemical diaphragm pump is crucial; it can mean the difference between efficient operation and frequent maintenance issues." With a myriad of designs, materials, and operational capabilities, understanding the unique requirements of your application is paramount to making an informed decision.

Chemical diaphragm pumps are known for their versatility and reliability in handling a variety of fluids, ranging from corrosive chemicals to viscous substances. Their ability to provide precise flow control while minimizing leakage makes them a preferred choice in many industries, including pharmaceuticals, water treatment, and chemical processing. By considering factors such as pump material compatibility, flow rate, and pressure requirements, users can ensure that they select a pump that not only meets their immediate needs but also accommodates future demands.

Ultimately, the process of choosing the right chemical diaphragm pump involves a thorough evaluation of both the operational environment and the specific requirements of the application. With advancements in technology and an expanding range of options available, making a well-informed selection has become more crucial than ever for optimizing performance and ensuring long-term reliability.

Understanding the Basics of Chemical Diaphragm Pumps and Their Applications

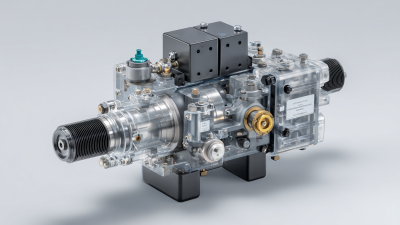

Chemical diaphragm pumps are specialized devices designed to transfer a variety of corrosive and viscous fluids in industrial and laboratory settings. Their fundamental operation relies on a diaphragm that flexes to create a pressure differential, allowing fluid to be drawn into the chamber and then expelled through discharge valves. This design not only minimizes leaks but also prevents the fluid from coming into contact with moving parts, making them ideal for handling hazardous chemicals and ensuring safety in operations.

Understanding the applications of diaphragm pumps is crucial when selecting the right model for specific needs. These pumps are commonly used in industries such as pharmaceuticals, water treatment, and food processing, where the integrity of the fluid is paramount. Their ability to handle aggressive chemicals and provide precise flow rates makes them suitable for tasks like dosing, transferring, and process control. Factors such as the chemical composition of the fluids, the required flow rate, and the operating environment must be considered to ensure optimal performance and longevity of the pump in various applications.

Key Factors Influencing the Selection of Chemical Diaphragm Pumps

When selecting the right chemical diaphragm pump, several key factors come into play that can significantly influence performance and suitability for specific applications. One of the most crucial aspects is the fluid compatibility with the diaphragm material. A study conducted by the Chemical Process Industry Commission highlighted that over 50% of diaphragm pump failures are attributed to chemical incompatibility. Therefore, understanding the properties of the chemicals being transferred, such as pH, temperature, and viscosity, is essential for ensuring a long service life and efficient operation.

Another important consideration is the pump's flow rate and pressure rating requirements. According to a report by the International Pump Users Group, accurately matching the pump capacity to the system's needs can improve efficiency by up to 30%. This necessitates a thorough assessment of the system's operational parameters and the specific tasks the pump will perform. Additionally, features such as self-priming ability and ease of maintenance should be examined, as these can directly impact uptime and operational costs. By evaluating these factors carefully, users can make informed decisions that align with their operational needs and help optimize overall performance.

Comparative Analysis of Material Choices for Diaphragm Pumps

When selecting a chemical diaphragm pump, the choice of materials is critical to ensure compatibility with the fluids being handled and to maintain pump durability. Diaphragm pumps are typically constructed from a variety of materials, each with unique properties. Common diaphragm materials include Santoprene, PTFE, and rubber, while the pump body can be made from polypropylene, stainless steel, or aluminum. Understanding the properties and potential applications of these materials can help you make an informed decision.

For example, PTFE is a popular choice for applications involving aggressive chemicals due to its high resistance to corrosion and chemical attack, making it ideal for atmospheric and vacuum service environments. In contrast, polypropylene is lighter, has good corrosion resistance, and is often used for less aggressive fluids. When considering the environment in which the pump will operate, the physical and chemical properties of the material should be weighed carefully.

Tips: Always consult technical data sheets to ensure the selected materials align with the temperature and pressure conditions of your application. Additionally, be attentive to any potential wear and tear on the diaphragm material based on the nature of the fluids being pumped. Choosing the right material not only extends the life of your pump but can also improve overall efficiency and reduce maintenance costs.

Evaluating Flow Rate and Pressure Specifications for Optimal Performance

When selecting a chemical diaphragm pump, evaluating the flow rate and pressure specifications is crucial to ensure optimal performance tailored to your specific applications. Flow rate, typically measured in gallons per minute (GPM) or liters per minute (LPM), indicates how much fluid the pump can move in a given period. It's essential to match the pump's flow rate capabilities with your system's needs, as underperformance can lead to inefficiencies, while excessive flow can waste resources and cause unwanted turbulence in the system.

Pressure specifications are equally important and reflect the pump's ability to overcome system resistance. This includes the height to which the liquid needs to be pumped and the friction loss in the piping system. Understanding the required discharge pressure for your application will help in selecting a pump that can handle these demands without overexertion. It’s advisable to consider both the maximum and average pressure requirements, as an ideal pump can maintain performance across varying conditions. Balancing these two specifications ensures not only efficiency but also longevity of the pump in demanding environments, ultimately leading to reduced maintenance costs and improved operational reliability.

How to Choose the Right Chemical Diaphragm Pump for Your Needs

| Pump Model | Flow Rate (L/min) | Max Pressure (bar) | Material Compatibility | Power Source |

|---|---|---|---|---|

| Model A | 10 | 6 | Chemicals, Water | Electric |

| Model B | 20 | 8 | Acids, Bases | Pneumatic |

| Model C | 15 | 5 | Solvents, Oil | Electric |

| Model D | 25 | 10 | Wastewater, Slurry | Pneumatic |

| Model E | 30 | 12 | Biofuels, Alcohols | Electric |

Maintenance Considerations to Ensure Longevity of Diaphragm Pumps

Maintaining diaphragm pumps is crucial for ensuring their longevity and optimal performance in various applications, including chemical processing and wastewater treatment. According to a report by the Global Diaphragm Pump Market Analysis, regular maintenance can extend the life of a diaphragm pump by up to 50%. This is primarily achieved through routine inspections and timely replacements of wear components such as diaphragms and check valves, which are critical for maintaining pump efficiency.

One essential maintenance practice is to monitor the pump's operating conditions regularly. This includes checking for unusual vibrations, leaks, and temperature variations. A study by the Pump Industry Analysts found that improper operating conditions can lead to premature failure. Implementing a preventive maintenance schedule that includes these checks not only maximizes the pump's operational lifespan but also minimizes downtime, thereby optimizing overall productivity. Professionals recommend inspecting the lubrication system and ensuring it is clean and full, as inadequate lubrication can significantly reduce the lifespan of the pump components.

Lastly, it is vital to ensure that the diaphragm pump is operated within its designated parameters. Exceeding flow rates or pressures can create undue stress, leading to failures. According to the Hydraulic Institute, adhering to manufacturer-specified limits allows for not only enhanced durability but also safer operations in chemical handling environments. Prioritizing these maintenance considerations can significantly contribute to the effective lifespan of diaphragm pumps, ensuring they continue to function efficiently over time.

Related Posts

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

Top 5 Electric Diaphragm Pumps: Key Features and Benefits Explained

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.