How to Choose the Best Diaphragm Pump for Your Needs: A Comprehensive Guide

Choosing the right diaphragm pump for your specific needs can significantly enhance efficiency in various applications, from industrial processes to environmental management. A diaphragm pump is a positive displacement pump that utilizes a flexible diaphragm to move fluids, making it an ideal choice for handling a wide range of liquids, including corrosive substances, slurries, and even food products. With the market offering a myriad of options, understanding the core features and capabilities of diaphragm pumps is crucial in making an informed decision.

As you embark on the journey of selecting a diaphragm pump, it is important to consider several key factors that influence performance, including the type of fluid, the required flow rate, and the operating environment. Additionally, you'll need to assess the pump’s material compatibility, maintenance requirements, and overall operational efficiency. This comprehensive guide will walk you through these considerations, ensuring that you choose the best diaphragm pump tailored to your unique requirements, ultimately leading to enhanced productivity and reliability in your operations.

Understanding Diaphragm Pumps and Their Applications

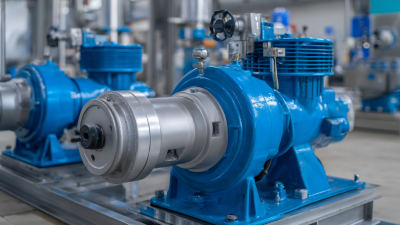

Diaphragm pumps are versatile devices used in a wide range of applications, from chemical processing to food and beverage industries. They work by utilizing a flexible diaphragm that moves back and forth to create a vacuum, drawing fluids into the pump and then expelling them. This simple yet effective mechanism makes diaphragm pumps inherently self-priming and capable of handling various fluid types, including viscous, shear-sensitive, and abrasive materials. According to a report by Research and Markets, the global diaphragm pump market is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2021 to 2026, underlining their increasing adoption across diverse sectors.

In industrial settings, diaphragm pumps are favored for their ability to handle hazardous materials safely, as they operate without any seals that could leak. Applications in the wastewater treatment sector highlight their efficiency in transferring sludge and various fluids with solid content. A study by MarketsandMarkets has indicated that the wastewater management segment accounts for a significant portion of diaphragm pump usage, reflecting the growing need for reliable pumping solutions in environmental management. As industries prioritize safety and compliance with stringent regulations, diaphragm pumps are becoming an integral component in facilitating effective and safe fluid movement, emphasizing their importance in maintaining operational efficiency across different applications.

Key Factors to Consider When Choosing a Diaphragm Pump

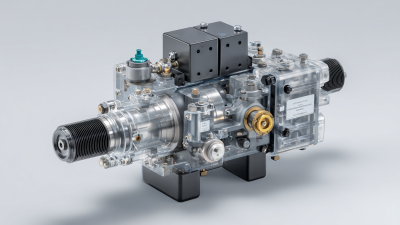

When choosing a diaphragm pump, several key factors should be considered to ensure it meets your specific needs. First and foremost, you must evaluate the materials used in the pump construction. The compatibility of the pump materials with the fluids being pumped is critical. Depending on the nature of the fluid, such as corrosive chemicals or viscous slurries, opting for materials that resist wear and chemical reaction will enhance the longevity and effectiveness of the pump.

Another significant factor is the pump's flow rate and pressure capabilities. Understanding the required flow rate for your application helps in selecting a pump that can efficiently handle the tasks at hand without causing damage or excessive wear. Additionally, consider the pressure rating, as a pump that operates at pressure levels too high or low for your needs may lead to inefficient performance or even failure. Lastly, evaluate the pump's size and connectivity options to ensure it fits well within your existing system and integrates seamlessly with other equipment.

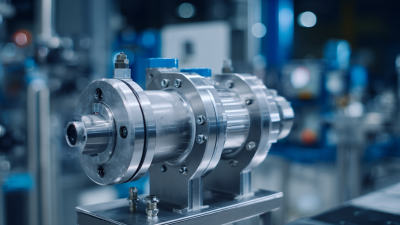

Types of Diaphragm Pumps and Their Specific Uses

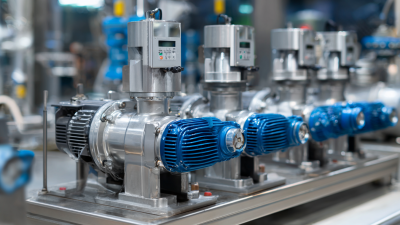

Diaphragm pumps are versatile devices used across various industries due to their ability to handle different types of fluids, including slurries, viscous materials, and corrosive liquids. The primary types of diaphragm pumps include air-operated double diaphragm (AODD) pumps, electric diaphragm pumps, and hydraulic diaphragm pumps, each tailored for specific applications. According to a market research report by Grand View Research, the global diaphragm pump market is projected to reach $4.25 billion by 2026, indicating a significant reliance on these pumps in sectors such as chemical processing, water and wastewater management, and food and beverage industries.

AODD pumps are particularly favored for their portability and efficiency in transferring aggressive liquids, making them ideal for the chemical manufacturing sector, where precise handling of hazardous materials is crucial. Electric diaphragm pumps, on the other hand, offer superior control and automation capabilities, which are essential for industries requiring reliable fluid delivery at controlled rates, such as pharmaceuticals and cosmetics. Lastly, hydraulic diaphragm pumps are known for their high flow rates and pressure capabilities, making them suitable for heavy-duty applications like mining and construction. As each type is designed with distinct operational parameters and material compatibilities, understanding their specific uses is vital for selecting the right pump to meet operational demands efficiently.

Diaphragm Pump Types and Their Specific Uses

Maintenance Tips for Prolonging the Life of Your Diaphragm Pump

To ensure the longevity and optimal performance of your diaphragm pump, regular maintenance is key. First and foremost, routine inspections should be conducted to check for any signs of wear or damage. Look for leaks, cracks, or any irregularities in the diaphragm and other components. Regularly replacing worn parts can prevent more significant issues down the line, ensuring that the pump operates efficiently.

Another essential maintenance tip is to keep the diaphragm pump clean. After each use, it’s advisable to flush the system with a suitable cleaning solution to remove any residual materials that could cause blockages or corrosion. Additionally, ensure that all fittings and connections are tightened to prevent leaks. Finally, maintaining the appropriate operating conditions, including monitoring pressure and flow rates, can significantly extend the life of your pump. By adhering to these practices, you can maximize the performance and reliability of your diaphragm pump.

Cost and Budget Considerations for Diaphragm Pumps

When considering the purchase of a diaphragm pump, understanding the cost and budget implications is crucial for making an informed decision. Diaphragm pumps come in a wide range of prices, influenced by factors such as size, materials, and intended applications. It is essential to assess your specific needs and choose a pump that balances performance with cost-effectiveness. High-quality materials may initially seem more expensive, but investing in durability can lead to lower maintenance and replacement costs over time.

Additionally, it's important to factor in any ancillary costs associated with the pump. This includes installation expenses, potential modifications to existing systems, and ongoing operational costs such as energy consumption. Reviewing the total cost of ownership can provide a clearer financial picture, helping to ensure that your investment aligns with your budget constraints. Analyzing both the initial purchase price and ongoing expenses will aid in identifying the diaphragm pump that not only meets your operational requirements but also remains financially viable in the long run.

How to Choose the Best Diaphragm Pump for Your Needs: A Comprehensive Guide - Cost and Budget Considerations for Diaphragm Pumps

| Pump Type | Material | Flow Rate (GPM) | Max Pressure (PSI) | Cost ($) | Best Applications |

|---|---|---|---|---|---|

| Air-Operated | Aluminum | 5-60 | 80 | 200-700 | Water treatment, chemical transfer |

| Electric | PP (Polypropylene) | 3-28 | 60 | 150-400 | Food processing, wastewater management |

| Hydraulic | Stainless Steel | 2-50 | 150 | 300-800 | Chemical handling, industrial applications |

| Diaphragm | PVC | 1-20 | 40 | 100-250 | Aquarium, laboratory use |

| Vacuum | Nylon | 0.5-10 | 30 | 50-150 | Food packaging, lightweight material transfer |

Related Posts

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

Top 10 Benefits of Using Pump Systems for Efficient Fluid Management

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.