How to Choose the Right Chemical Metering Pump for Your Needs?

Choosing the right chemical metering pump is crucial for various industries. It impacts efficiency, safety, and cost. According to a report by Allied Market Research, the global chemical metering pump market is projected to reach $8.8 billion by 2027. This illustrates the growing importance of selecting the right equipment.

Expert John Smith, a leading authority in fluid dynamics, states, “The efficiency of chemical metering systems can significantly affect operational success.” His insight emphasizes that making informed choices matters. Not all pumps are created equal. Each application may require different specifications, such as flow rate and pressure.

Understanding the nuances of chemical metering pumps can be challenging. Many users overlook factors like compatibility with fluids. These choices can lead to inefficiencies and potential failures in the system. Real-world applications require careful consideration. Failing to do so may result in costly downtime or unexpected expenses. Always remember that the right decision can enhance both productivity and safety.

Understanding the Basics of Chemical Metering Pumps

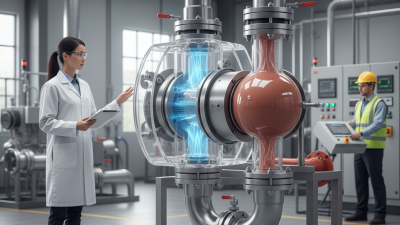

Chemical metering pumps play a critical role in various industries. These devices accurately deliver chemicals in controlled amounts. Understanding how they function is essential for effective usage.

The basics of a chemical metering pump revolve around its mechanism. These pumps use a precise action, often relying on diaphragm or piston technology. They can handle a wide range of fluids, including corrosive substances and viscous liquids. However, choosing the right one requires careful consideration. Not all pumps are compatible with every chemical.

Another important aspect to consider is the flow rate. Each application has specific flow requirements. Selecting a pump with the wrong flow rate can lead to inefficiencies. Additionally, reflect on maintenance needs. Some pumps require regular checks, while others are more self-sufficient. Balancing accuracy, compatibility, and maintenance can be challenging. Each choice comes with its own set of trade-offs.

Identifying Key Factors for Selection

Choosing the right chemical metering pump isn't always straightforward. Start by understanding your application needs. Consider the flow rate required for your processes. It's important to gauge the pressure conditions. Pumps handle different tasks, so identifying the specifics helps narrow choices.

Next, materials of construction matter. Your fluid's chemical properties influence pump durability. Some substances may corrode certain materials. Always review compatibility. It can save you from costly failures. A pump failing too early results in downtime and repairs, which can be frustrating.

Another aspect to reflect on is control options. Do you need automatic adjustments or manual settings? Each approach has benefits and drawbacks. If you prefer automation, ensure the pump has reliable control features. For simple tasks, manual might suffice. Keep these factors in mind as you make your choice. Selecting a pump often involves trial and error. Think about what works best for your needs, and don't rush the decision.

Evaluating Pump Types and Technologies

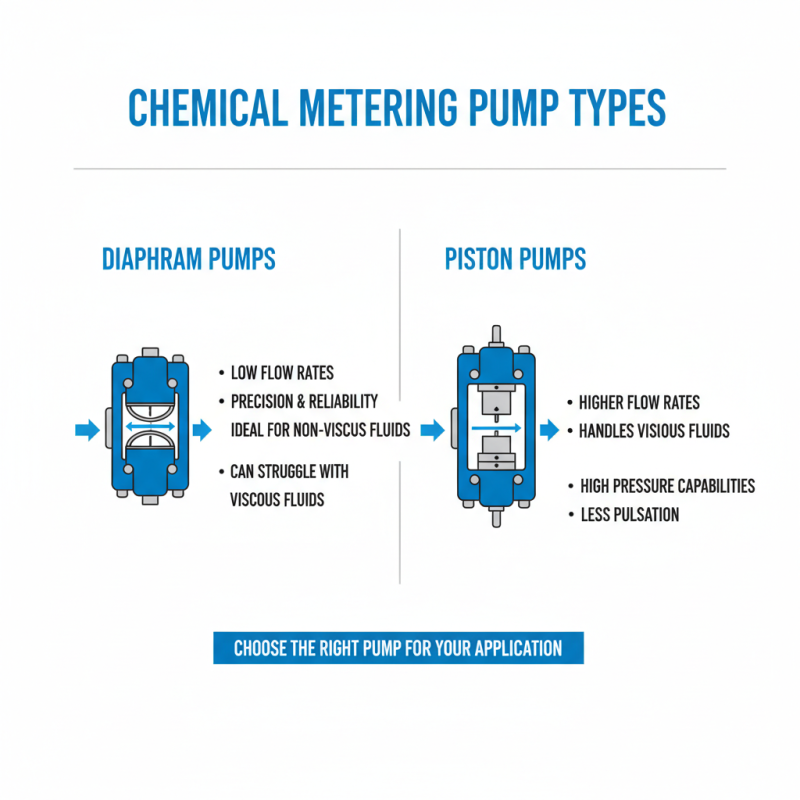

When evaluating pump types and technologies, clarity is crucial. Chemical metering pumps come in various designs. Each serves a specific purpose. For low flow rates, diaphragm pumps might be ideal. They offer precision and reliability. However, they can struggle with viscous fluids.

Consider your application needs. Gear pumps handle thicker substances well. They provide smooth flow and can manage high pressures. But, they may not offer the same accuracy in dosing as diaphragm pumps. Decide what matters most—precision, flow rate, or chemical compatibility. Think about maintenance too. Some systems require regular checks, impacting overall efficiency.

**Tip**: Always consult with your team. They can offer insights on past experiences. Review your operating conditions. Different environments can affect performance. What works in one scenario might fail in another. Keeping an open mind is essential. Consider trialing pumps before making a final decision. Sometimes, the right choice isn't obvious until you see it in action.

Determining Performance Specifications and Requirements

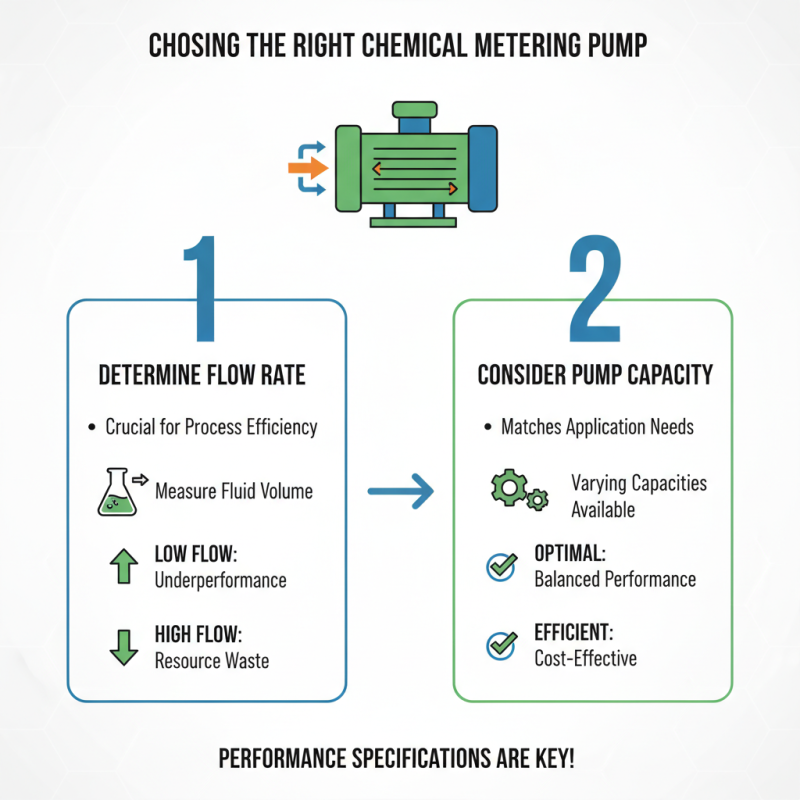

Choosing the right chemical metering pump requires careful consideration of performance specifications. Start by determining the flow rate needed for your application. Different pumps offer varying capacities, which can significantly affect your process efficiency. Measure the amount of fluid you will need to transport. A flow rate too low can lead to underperformance, while a rate that’s too high can waste resources.

Next, consider the pressure requirements. What is the maximum pressure needed for your operations? A pump must withstand the pressure levels in your system without failure. Check the materials used in pump construction as well. Corrosion resistance is crucial for longevity. Remember, a pump that may seem suitable might not be durable enough for aggressive chemicals.

Take a step back and assess the maintenance needs. Some pumps require more frequent servicing than others. This can impact long-term costs. Look for user feedback on reliability and maintenance ease. Perfection is hard to find; even the best pumps can face issues. Be open to adjustments and learning as you gauge their performance in practical settings.

Assessing Maintenance and Support Options

When selecting a chemical metering pump, maintenance and support options play a crucial role. These pumps often handle corrosive fluids. An understanding of maintenance needs is vital. According to industry reports, about 40% of pump failures are linked to inadequate maintenance. Regular checks can prevent costly downtime.

Support options are equally important. Many manufacturers offer different levels of technical support. This can range from basic documentation to 24/7 assistance. A report by a leading pump industry analyst states that businesses with access to robust support experience 30% less downtime. Ensure your supplier provides reliable support resources.

Certain designs are easier to maintain. Pumps with modular components simplify repairs. This can save both time and cost. However, some models might lack essential support documentation. It's essential to consider how much time your team can devote to maintenance. If your team is stretched thin, prioritize user-friendly options. A good balance of ease and support is key to long-term success.

How to Choose the Right Chemical Metering Pump for Your Needs? - Assessing Maintenance and Support Options

| Feature | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Flow Rate (GPH) | 0-50 | 50-100 | 100-200 |

| Max Pressure (PSI) | 150 | 300 | 500 |

| Control Type | Manual | Automatic | Smart |

| Material Compatibility | Acids | Alkalis | Solvents |

| Maintenance Frequency | Monthly | Quarterly | Annually |

| Support Options | Email Support | Phone Support | On-site Support |

Related Posts

-

Understanding the Importance of Chemical Metering Pumps in Industrial Applications

-

Maximizing Efficiency in Industrial Processes with Advanced Electric Chemical Injection Pumps

-

Why Choose a Chemical Metering Pump for Precise Liquid Handling in Your Industry

-

What is a Pneumatic Pump? How It Works and Its Applications Explained

-

Understanding the Role of Chemical Pumps in Modern Industrial Applications

-

Top 10 Benefits of Solar Pumps for Sustainable Water Solutions

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.