Why Choose a Chemical Metering Pump for Precise Liquid Handling in Your Industry

In today's industrial landscape, the demand for precision and efficiency in liquid handling has never been higher. According to a recent report by Transparency Market Research, the global chemical metering pump market is projected to grow at a CAGR of 5.7% from 2023 to 2030, driven by increasing automation and stringent regulations in various sectors including water treatment, chemical processing, and pharmaceuticals. The need for accurate dosing and effective control of liquid flow has positioned chemical metering pumps as essential tools in achieving operational efficiency and maintaining compliance with safety standards.

Chemical metering pumps offer unparalleled advantages in precise liquid handling. Their ability to provide a consistent flow rate ensures that the right amount of chemical is delivered, minimizing waste and enhancing overall process performance. With increasing environmental regulations and the need for sustainability, industries are turning to these pumps not just for compliance but also to optimize their resource usage. Industry reports indicate that businesses employing chemical metering pumps can achieve reductions in chemical consumption of up to 30%, translating to significant cost savings and a smaller ecological footprint.

Chemical metering pumps offer unparalleled advantages in precise liquid handling. Their ability to provide a consistent flow rate ensures that the right amount of chemical is delivered, minimizing waste and enhancing overall process performance. With increasing environmental regulations and the need for sustainability, industries are turning to these pumps not just for compliance but also to optimize their resource usage. Industry reports indicate that businesses employing chemical metering pumps can achieve reductions in chemical consumption of up to 30%, translating to significant cost savings and a smaller ecological footprint.

As innovation continues to shape the future of industrial processes, the integration of advanced technology in chemical metering pumps is set to enhance their functionality even further. Features such as digital controls and real-time monitoring capabilities are poised to revolutionize liquid handling operations, ensuring manufacturers and service providers can meet the demands of their customers while driving efficiency and profitability in the years to come.

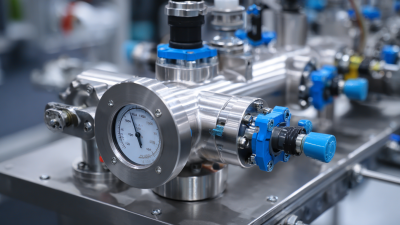

Understanding the Functionality of Chemical Metering Pumps in Liquid Handling

Chemical metering pumps play a crucial role in

precise liquid handling across various industries, including water treatment,

pharmaceuticals, and food processing.

These pumps are designed to deliver a consistent flow of chemicals with a high degree of accuracy,

minimizing the risk of over- or under-dosing. According to a report by MarketsandMarkets, the global chemical

metering pumps market is projected to reach $4.56 billion by 2026,

reflecting an annual growth rate of 5.1%. This growth underscores

the increasing demand for reliable fluid handling solutions that maintain strict dosing requirements.

The functionality of chemical metering

pumps is characterized by their ability to provide precise control over the chemical injection process.

They utilize various technologies, such as diaphragm,

peristaltic, and gear pumps, to

achieve the desired flow rates. Research published in the Journal of Chemical Engineering indicates that

typical error rates in dosing can be as low as 1%, enhancing

operational efficiency and product quality. Moreover, their robust design and adaptability to various

chemical properties make them suitable for industries handling corrosive or viscous liquids.

This versatility is essential, especially in sectors like oil and gas,

where precise chemical dosing is vital for safety and compliance.

Identifying Key Industries That Benefit from Precise Liquid Measurements

In various industries, precise liquid measurements are paramount for ensuring efficiency and safety. Key sectors such as pharmaceuticals, food and beverage, and wastewater treatment are increasingly deploying chemical metering pumps and advanced liquid handling systems. These sectors benefit significantly from the accuracy and reliability provided by contact and non-contact level sensors, which facilitate the ideal transfer and dosage of liquid samples.

The global market for smart flow meters is anticipated to grow substantially, with projections indicating a rise from approximately $283 million in 2025 to around $385 million by 2033. This growth highlights the increasing reliance on automated liquid handling processes and devices across multiple applications. By opting for advanced measuring technologies such as ultrasonic, capacitive, and pressure sensors, industries are not only enhancing productivity but are also ensuring compliance with stringent regulatory standards, ultimately leading to improved operational outcomes.

Benefits of Chemical Metering Pumps Across Key Industries

Evaluating the Advantages of Using Chemical Metering Pumps Over Other Solutions

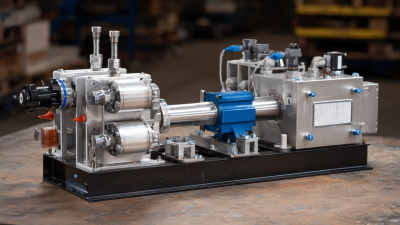

Chemical metering pumps offer significant advantages over traditional pumping solutions when it comes to precise liquid handling in various industrial applications. One of the most compelling benefits is their ability to deliver consistent and accurate flow rates, regardless of changes in pressure or viscosity. This precision is crucial in processes where exact chemical concentrations are vital for safety, compliance, and product quality. With features such as adjustable outputs and scalable designs, these pumps can be tailored to specific operational requirements, enhancing efficiency and reducing waste.

In contrast to standard pumps that may struggle with the complexities of chemical dosing, metering pumps are specifically engineered for reliability and accuracy. They typically incorporate advanced control systems and monitoring capabilities, allowing for real-time adjustments and troubleshooting. This adaptability not only minimizes the risk of over- or under-dosing but also contributes to safer work environments. As industries increasingly prioritize sustainability and efficiency, the use of chemical metering pumps emerges as a smart investment, providing the reliability and performance needed for modern manufacturing and processing demands.

Tips for Selecting the Right Chemical Metering Pump for Your Specific Needs

When selecting a chemical metering pump for your specific needs, understanding the unique requirements of your application is crucial. According to a report by MarketsandMarkets, the global chemical pump market is projected to reach $45.23 billion by 2025, emphasizing the growing importance of efficiency and precision in liquid handling across industries. Start by evaluating the flow rate required for your processes—common ranges for metering pumps are typically from 0.1 to 500 GPH, which can significantly vary based on the nature of your operations.

Another key factor to consider is the pump's compatibility with the chemicals being handled. A survey by Grand View Research highlighted that 36% of industries prioritize material compatibility when choosing metering pumps. Always verify whether the pump materials can withstand the corrosive nature of the substances, as improper choices can lead to premature failure and costly downtimes. Additionally, assess the pump's control capabilities, such as manual vs. automated dosing, to ensure it aligns with your operational demands. Selecting a pump with the right specifications will not only boost efficiency but also enhance safety in your chemical handling processes.

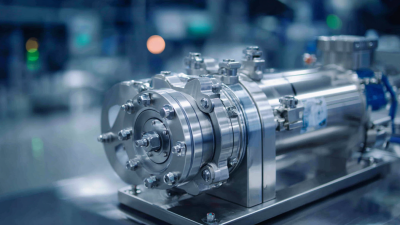

Best Practices for Maintenance and Operation of Chemical Metering Pumps

Proper maintenance and operation of chemical metering pumps are essential for achieving optimal performance and ensuring safety in various industrial applications. Regular inspection is a cornerstone of best practices, encompassing checks for leaks, wear on seals, and the overall condition of the pump. Implementing a routine maintenance schedule can help identify potential issues before they escalate, thus minimizing downtime and extending the lifespan of the equipment. Additionally, keeping a comprehensive record of maintenance activities helps in tracking performance trends and detecting irregularities over time.

Operational best practices also play a critical role in the effective use of chemical metering pumps. It is crucial to calibrate the pump accurately to ensure precise liquid handling, as this directly impacts dosing accuracy. Operators should be well-trained in the specific requirements of the chemicals being metered, including their viscosity and reactivity. Understanding the pump's delivery capabilities and setting appropriate flow rates can prevent operational failures and enhance process efficiency. Regularly reviewing operational parameters, such as pressure and temperature, will further ensure that the pumps function within their intended specifications.

Why Choose a Chemical Metering Pump for Precise Liquid Handling in Your Industry - Best Practices for Maintenance and Operation of Chemical Metering Pumps

| Dimension | Value |

|---|---|

| Flow Rate (L/hour) | 10 - 200 |

| Pressure Range (bar) | 1 - 10 |

| Viscosity (cP) | 1 - 1000 |

| Common Applications | Water Treatment, Chemical Processing, Food & Beverage |

| Power Supply (V) | 110 - 240 |

| Maintenance Frequency (months) | 6 - 12 |

| Expected Lifespan (years) | 5 - 10 |

Related Posts

-

Understanding the Importance of Chemical Metering Pumps in Industrial Applications

-

Maximizing Efficiency in Industrial Processes with Advanced Electric Chemical Injection Pumps

-

Revolutionizing Efficiency in Oil Fields: The Role of Chemical Injection Systems

-

Understanding the Role of Chemical Pumps in Enhancing Water Treatment Efficiency

-

2025 How to Choose the Right Liquid Pump for Your Industrial Needs

-

2025 Top 5 Solar Pump Systems: Revolutionizing Water Solutions for Sustainable Living

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.