2026 Best Fluid Pumps for Your Industrial Needs?

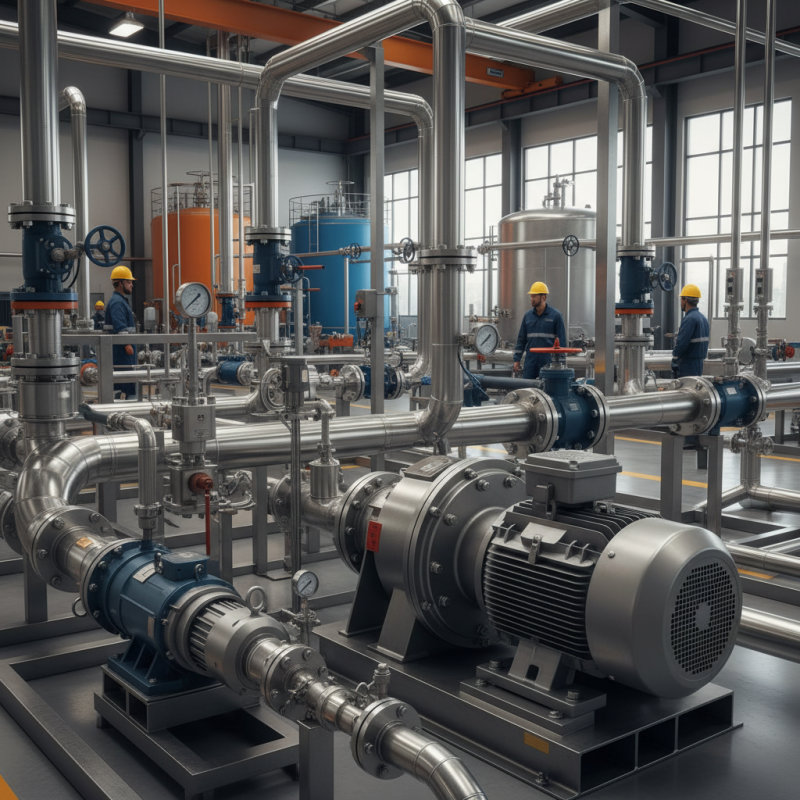

In the industrial world, choosing the right fluid pumps is crucial. These devices move liquids efficiently, playing a key role in various operations. Whether for manufacturing, chemical processing, or HVAC systems, fluid pumps ensure smooth workflows.

Different types of fluid pumps exist. For example, positive displacement pumps excel in precision, while centrifugal pumps are favored for their speed. Each pump type has its own strengths and weaknesses. Understanding these details can lead to better decisions. It is essential to consider factors like viscosity, temperature, and flow rate when selecting a pump.

Though many options are available, not all pumps meet every need. Users often overlook specific requirements, leading to inefficiencies. Common pitfalls include choosing an oversized pump or one that lacks durability. Careful evaluation of these aspects can help avoid costly mistakes in fluid handling applications.

Types of Fluid Pumps Used in Industrial Applications

Fluid pumps are essential in various industrial applications. They transfer liquids efficiently across different systems. Choosing the right type of pump is crucial. Here are some common types used in industries.

Centrifugal pumps are widely used for their ability to move large volumes of fluid. They are effective for clear liquids. These pumps create a flow through rotational energy. However, they may struggle with viscous fluids. Always assess the liquid's properties before selecting.

Positive displacement pumps are another category. They ensure a constant flow, regardless of pressure changes. These pumps work well with thicker fluids. One downside is their maintenance. They often require more upkeep compared to centrifugal options.

Tip: Regular maintenance prolongs pump life. Check seals and bearings frequently. Neglect can lead to failures.

Diaphragm pumps are used for sensitive applications. They handle corrosive fluids without contamination. These pumps use a flexible diaphragm to move the liquid. They can be complex and may need training for proper operation.

Tip: Proper training boosts efficiency. Always understand the equipment before use. Familiarize yourself with the manual.

Selecting the right pump is not always straightforward. Each type has its benefits and drawbacks. Take time to evaluate your specific needs.

2026 Best Fluid Pumps for Your Industrial Needs

Key Features to Consider When Choosing Fluid Pumps

When selecting fluid pumps for industrial applications, several key features demand attention. The pump's flow rate is crucial. Applications may require pumps with a flow rate ranging from 1 to 8,000 gallons per minute. Understanding your specific needs in this area can optimize performance and efficiency.

Another important aspect is the pump material. It impacts durability and resistance to corrosion. Common materials include stainless steel, plastic, and cast iron. Studies show that materials can account for as much as 50% of failure rates in harsh environments. Therefore, choosing the right material is vital for long-term operation.

Energy consumption is another consideration. Efficient pumps can reduce operating costs significantly. Research indicates that energy costs can exceed initial equipment costs over time. It’s prudent to look for designs that enhance efficiency while adhering to operational demands. Although many pumps claim high efficiency, real-world performance may vary. Continuous assessment post-installation can reveal discrepancies between expected and actual results.

Top Brands and Manufacturers of Fluid Pumps in 2026

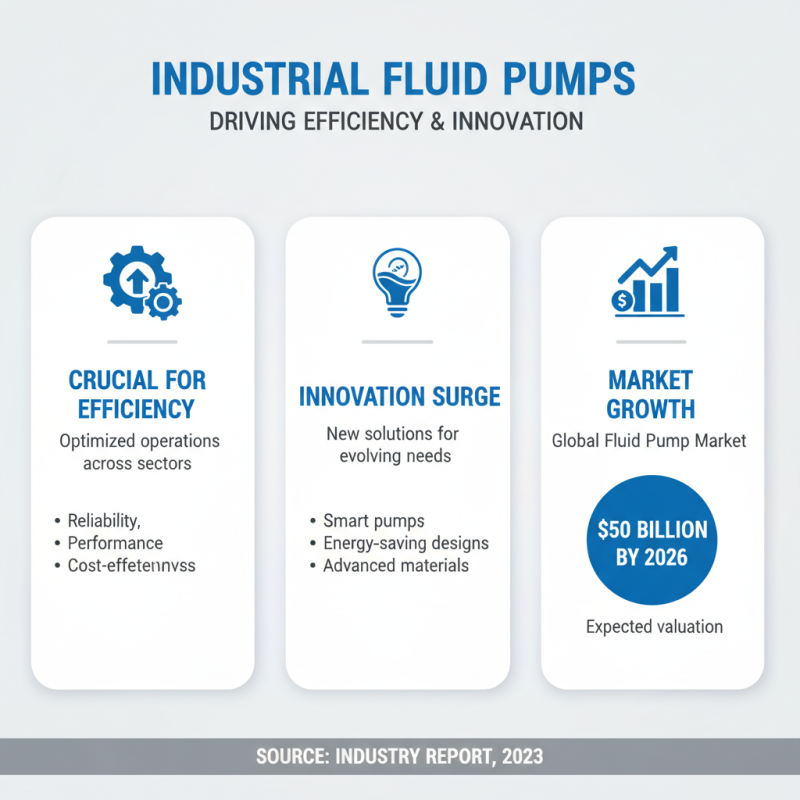

Choosing the right fluid pump is crucial for industrial efficiency. The market has seen a surge in demand for innovative solutions. According to a recent industry report, the global fluid pump market is expected to reach $50 billion by 2026. This growth reflects the rising need for reliable and efficient pumping systems across various sectors.

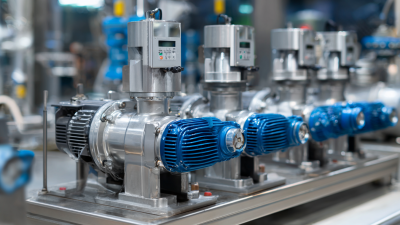

In 2026, key manufacturers are focusing on advanced technology. They aim to enhance energy efficiency and reduce operational costs. The demand for smart pumps, which integrate IoT capabilities, is increasing. These pumps can provide real-time data and remote monitoring. However, some companies struggle with integrating these technologies effectively. Balancing cost and innovation remains a significant challenge.

Additionally, sustainability is becoming a priority. Many manufacturers are investing in eco-friendly materials and processes. Reports indicate that fluid pumps contribute significantly to industrial energy consumption. Thus, choosing efficient models can greatly impact overall carbon footprints. Despite these advancements, some industries still rely on outdated systems. This gap highlights the need for ongoing education and updates in technology to meet modern standards.

Maintenance Tips for Maximizing Pump Performance

Regular maintenance of fluid pumps is essential for optimal performance. Neglect can lead to decreased efficiency and unexpected breakdowns. Implementing a routine maintenance schedule can help avoid costly downtimes.

One key tip is to regularly check for leaks. A small leak can lead to significant loss over time. Keep an eye on seals and joints. Also, ensure that the pump's filters are cleaned or replaced as needed. Clogged filters can restrict flow and decrease performance.

Another important aspect is monitoring operating temperatures. If a pump runs too hot, it can damage internal components. Use temperature gauges to track performance. Make adjustments if you notice any anomalies. A good practice is to maintain a log of operational data for future reference. This can help identify patterns and issues early on.

2026 Best Fluid Pumps for Your Industrial Needs

| Pump Type | Max Flow Rate (GPM) | Max Pressure (PSI) | Power Source | Applications | Maintenance Tips |

|---|---|---|---|---|---|

| Centrifugal Pump | 100 | 150 | Electric | Water, Chemicals | Regularly check impeller and casing for wear. |

| Positive Displacement Pump | 75 | 200 | Hydraulic | Food, Pharmaceuticals | Inspect seals and gaskets regularly for leaks. |

| Diaphragm Pump | 50 | 100 | Pneumatic | Slurries, Corrosives | Lubricate moving parts and check air supply pressure. |

| Peristaltic Pump | 30 | 50 | Electric | Gentle Fluid Transfer | Change tubing regularly to prevent contamination. |

| Gear Pump | 40 | 150 | Electric | Oil, Viscous Liquids | Check fluid viscosity to avoid overheating. |

Future Trends in Fluid Pump Technology for Industry

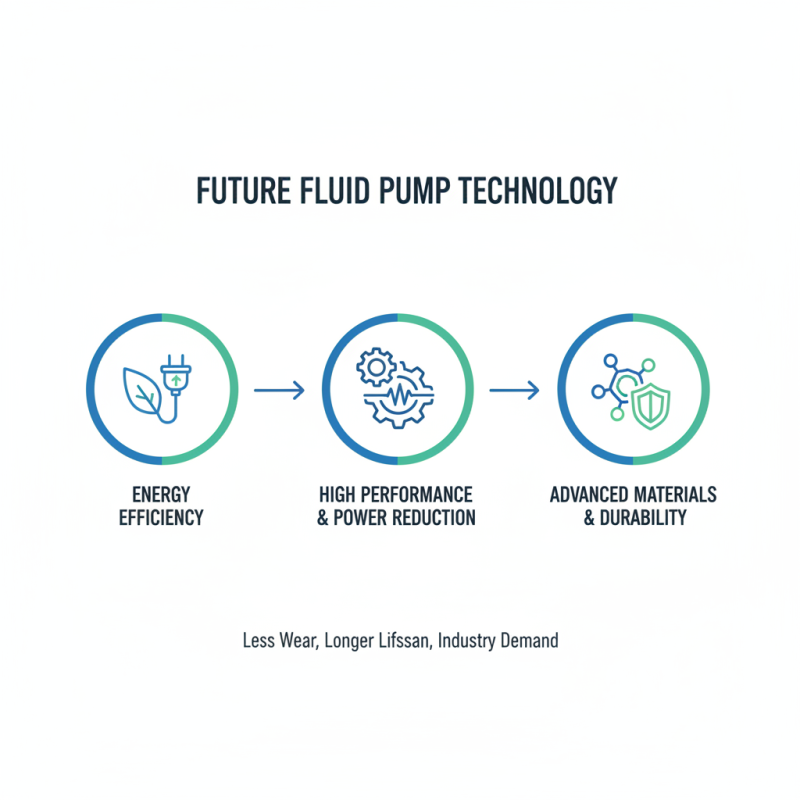

The future of fluid pump technology is evolving rapidly. Innovative designs are focusing on energy efficiency. Many industries demand pumps that consume less power while maintaining high performance. These pumps often utilize advanced materials for better durability and reduced wear.

Automation is another key trend. Smart pumps can monitor performance in real-time. They provide crucial data analytics to optimize operations. This can lead to significant cost savings. Yet, reliance on technology can raise concerns. What happens if the system fails? Human oversight is still essential.

Sustainability is a growing priority. Manufacturers are developing eco-friendly options. These pumps aim to minimize waste. It’s important to strike a balance between innovation and practicality. Will all new technologies meet industry standards? Adaptation requires careful consideration and testing.

Related Posts

-

10 Essential Tips for Choosing the Best Fluid Pumps for Your Project

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.