2026 Best Chemical Pumps for Industrial Applications?

In industrial settings, efficiency and safety are paramount. One crucial component that can greatly affect operations is chemical pumps. These pumps handle various substances, from corrosive liquids to viscous fluids. Selecting the right model is vital.

The year 2026 promises advancements in chemical pumps that can enhance performance. New technologies can improve durability and operational efficiency. However, many industries still struggle with outdated equipment. It's essential to recognize that investing in modern solutions may lead to significant long-term benefits.

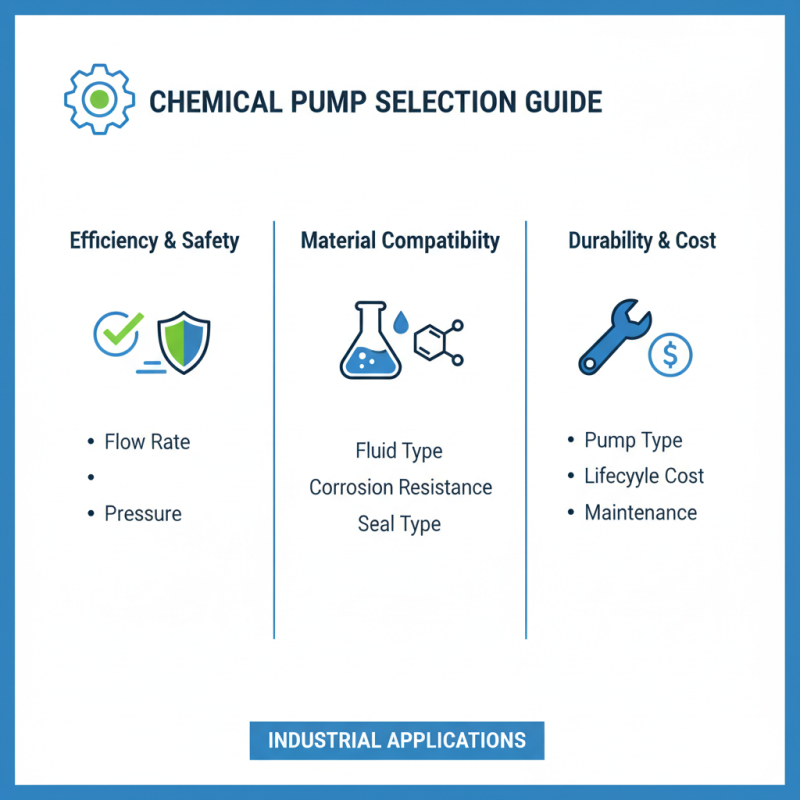

Choosing the best chemical pumps requires careful consideration. Factors like material compatibility, flow rate, and energy efficiency play critical roles. The market offers a range of options, making it easy yet overwhelming. Reflecting on the specific needs of your application can guide a more informed decision.

Overview of Industrial Chemical Pumps and Their Applications

Industrial chemical pumps serve a critical role in a variety of processes. They transfer fluids and handle corrosive materials efficiently. These pumps are essential in industries like pharmaceuticals, chemicals, and water treatment. According to recent market research, the global chemical pump market is projected to reach $40 billion by 2026. This growth highlights the increasing dependency on these pumps.

Different types of chemical pumps exist. Diaphragm pumps are useful for gentle handling. Centrifugal pumps, meanwhile, excel in high flow rates. However, many facilities still face challenges in selecting the right type. Cost considerations often overshadow technical specifications. Moreover, reliability is a key concern. A breakdown can result in significant downtime and financial loss. Therefore, ongoing training for operators is paramount.

In terms of safety, chemical handling requires strict regulations. Mishandling can lead to catastrophic failures. Yet, not all facilities prioritize safety protocols. Investing in advanced monitoring technologies could mitigate risks. Reports indicate that up to 30% of chemical spills are due to pump failures. These statistics urge industries to revisit maintenance practices and invest smarter. Neglecting these details could jeopardize both safety and productivity.

Key Factors in Selecting Chemical Pumps for Industries

When selecting chemical pumps for industrial applications, several key factors come into play. Understanding the

specific type of chemicals being handled is crucial. Some chemicals may be corrosive

or abrasive, necessitating specialized materials for the pump. Always consider

the chemical compatibility to avoid potential failures.

Tip: Assess the viscosity of fluids. High-viscosity fluids

require pumps with different specifications.

The flow rate is another vital factor. Proper flow rate ensures efficient operations and prevents potential spills.

Inadequate flow can lead to equipment damage. It’s essential to match the pump's

capacity with the needs of your process.

Tip: Monitor the operating conditions of the pump closely.

Changes in temperature and pressure can impact performance.

Installation and maintenance are often overlooked. A poorly installed pump can lead to leaks

or reduced lifespan. Regular maintenance checks can help identify issues before they escalate into costly repairs. Always

document maintenance activities for future reference.

Top Chemical Pump Technology Trends for 2026

As industries evolve, chemical pump technology is advancing rapidly. A recent report predicts that the global chemical pump market will reach $6 billion by 2026, fueled by increased demand from the water treatment and oil & gas sectors. Innovations in material science are playing a vital role in enhancing pump durability and efficiency. For example, advanced composite materials can resist corrosion, which is critical in aggressive chemical environments.

Additionally, automation is becoming a major trend. The integration of IoT in pumping systems is set to improve operational efficiency. Sensors can provide real-time data on pump performance, enabling predictive maintenance. This reduces downtime and enhances productivity. According to a study, companies adopting smart pumping solutions reported a 20% reduction in maintenance costs.

Despite these advancements, challenges remain. Some users have struggled with the initial integration of these technologies into older systems. Training staff on new technology can be time-consuming and expensive. Moreover, the variability in chemical compositions makes standardization difficult. As we look to 2026, finding ways to address these issues is essential for manufacturers and end-users alike.

2026 Best Chemical Pumps for Industrial Applications

| Pump Type | Max Flow Rate (L/min) | Max Pressure (Bar) | Material Compatibility | Power Type | Efficiency (%) |

|---|---|---|---|---|---|

| Centrifugal Pump | 300 | 10 | Acids, Bases | Electric | 85 |

| Diaphragm Pump | 150 | 6 | Solvents, Oils | Pneumatic | 90 |

| Gear Pump | 120 | 15 | Chemicals, Fluids | Electric | 88 |

| Peristaltic Pump | 200 | 5 | Corrosive Liquids | Electric | 95 |

| Magnetic Drive Pump | 250 | 12 | Hazardous Materials | Electric | 87 |

Comparative Analysis of Leading Brands in Chemical Pumps

When selecting chemical pumps for industrial applications, there are numerous factors to consider. The choice can dramatically impact efficiency and safety. Not all pumps are created equal. Evaluating specifications is crucial for finding the right fit. Look for factors like flow rate and material compatibility. Different materials handle chemicals uniquely, affecting durability.

Some leading brands offer diverse models tailored for various needs. Yet, not every pump meets high expectations. Users often report operational issues, such as leaks or inadequate performance. Reflecting on these experiences can reveal trends. It’s vital to read reviews and conduct thorough comparisons to avoid pitfalls.

The design of a chemical pump should facilitate maintenance and troubleshooting. Complex systems may seem appealing, but they can complicate repairs. Simplicity can often lead to better long-term outcomes. Understanding your operational environment is key. Each application brings its own challenges, and no one-size-fits-all solution exists. Stay open to feedback and adjust your choices accordingly.

Maintenance and Safety Considerations for Chemical Pump Operations

When operating chemical pumps, safety is paramount. Regular maintenance prevents unexpected breakdowns that could lead to spills or leaks. Inspect seals, gaskets, and pipes routinely. A minor issue can escalate quickly if not addressed. Establish a routine inspection schedule to catch problems early.

Tips: Always wear protective gear. This includes gloves, goggles, and face shields to protect from splashes. Proper training for operators is essential. Ensure everyone understands the equipment and responds correctly in emergencies. Lack of knowledge can lead to accidents.

Safety measures also include proper storage of chemicals. Store them in units designated for hazardous materials. Ensure ventilation is adequate in work areas to prevent buildup of harmful fumes. It’s crucial to have spill kits readily available.

Tips: Conduct regular safety drills. This ensures the team knows how to act in an emergency. Do not overlook the need for a clean workspace. Clutter can create hazards and hinder quick responses. Regularly assess and reflect on safety protocols. Improving them can significantly enhance safety practices.

2026 Best Chemical Pumps for Industrial Applications

This chart displays the flow rates of various chemical pumps in industrial applications for the year 2026. Understanding these metrics can help in selecting the appropriate pump for specific operational needs while considering maintenance and safety aspects.

Related Posts

-

The Ultimate Guide to Choosing the Right Chemical Pumps for Your Needs

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

-

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

-

Understanding the Role of Chemical Pumps in Modern Industrial Applications

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.