Top 10 Benefits of Using Pump Systems for Efficient Fluid Management

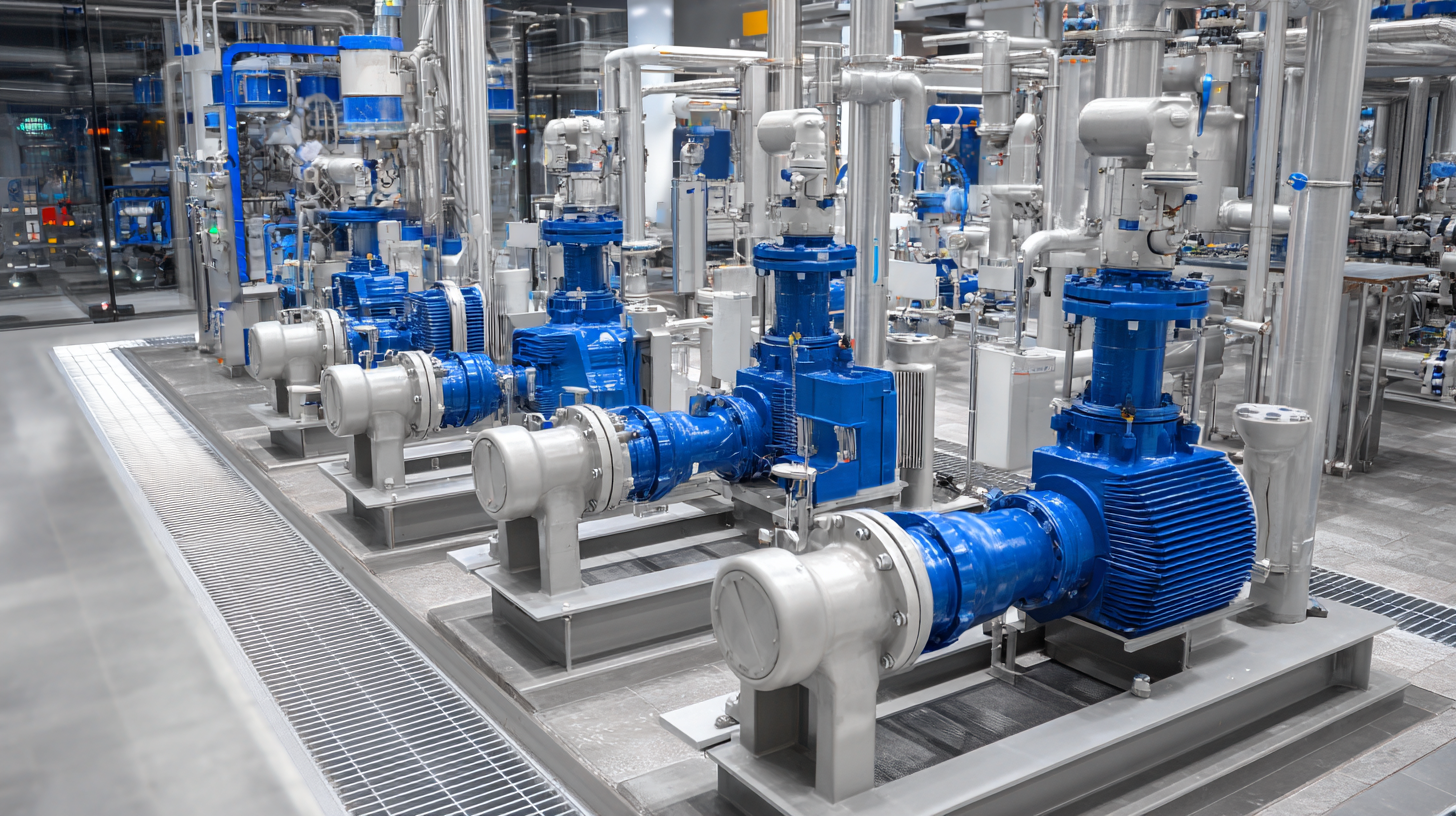

In the ever-evolving landscape of industrial fluid management, the implementation of pump systems has emerged as a critical factor for enhancing operational efficiency. According to John Smith, a renowned expert in fluid dynamics and pump technology, “Efficient pump systems are not just components; they are the lifeblood of any fluid management process.” This insight underscores the essential role that pump systems play in optimizing the flow and control of fluids across various sectors, from manufacturing to energy production.

The advantages of integrating advanced pump systems are manifold, offering not only increased efficiency but also substantial cost savings and improved sustainability. By exploring the top ten benefits of using pump systems, businesses can gain valuable insights into how these systems can streamline their operations, reduce waste, and enhance overall productivity. As industries continue to prioritize sustainability, the strategic application of pump systems serves as a pivotal approach to achieving both operational goals and environmental responsibility.

In this guide, we will delve into the crucial benefits that come with effective fluid management through pump systems, highlighting how they can transform operational practices and drive greater success in a competitive marketplace.

Advantages of Enhanced Fluid Control with Pump Systems

The use of pump systems in fluid management has revolutionized various industries by enhancing fluid control, which is critical for operational efficiency. According to a report by the Hydraulic Institute, optimized pump systems can reduce energy consumption by up to 30%, translating to significant cost savings for businesses. The precision offered by modern pumping solutions enables industries such as manufacturing and waste management to maintain consistent fluid flow rates, minimizing downtime and ensuring processes run smoothly.

Furthermore, enhanced fluid control through pump systems allows for better monitoring and management of liquid behaviors. The Global Water Intelligence report highlights that advanced pumping technologies can decrease the risk of leaks and spills, ultimately resulting in improved environmental sustainability. With proper fluid management, companies can adhere to stricter regulatory requirements while protecting natural resources. This dual benefit of cost efficiency and environmental responsibility is increasingly vital in today’s market, where sustainability is a top priority for both businesses and consumers.

Cost Efficiency: Reducing Operational Expenses through Pump Solutions

Efficient fluid management is crucial for minimizing operational expenses, and pump systems play a pivotal role in achieving this goal. By automating the movement and control of fluids, these systems reduce the need for manual labor and the potential for human error, which can lead to costly accidents or inefficient operations. The use of pumps allows for precise fluid transfer, ensuring that resources are utilized effectively, which directly contributes to lower operational costs.

Moreover, advanced pump technologies, such as variable speed drives and smart controls, enhance energy efficiency. By optimizing flow rates and energy consumption based on real-time demand, businesses can significantly cut down on electricity costs. Additionally, integrating pump systems with other process technologies can streamline operations, reduce waste, and prolong equipment lifespan, further supporting the bottom line. The overall savings from reduced maintenance, fewer spills, and efficient fluid transfer make investing in pump solutions a strategic decision for any organization aiming to enhance profitability while managing fluid resources responsibly.

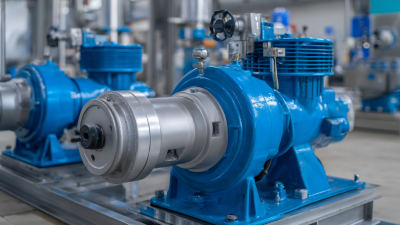

Improved Reliability: Ensuring Consistent Fluid Delivery with Pumps

Efficient fluid management is crucial across various industries, and one of the most significant benefits of using pump systems is improved reliability. According to the Hydraulic Institute’s latest report, pump systems account for approximately 20-25% of industrial energy consumption. By utilizing modern pump technologies, facilities can minimize downtime and ensure consistent fluid delivery, which is essential for maintaining operational efficiency. The reliability of pump systems reduces the risk of unexpected failures, leading to lower maintenance costs and minimized production disruptions.

Efficient fluid management is crucial across various industries, and one of the most significant benefits of using pump systems is improved reliability. According to the Hydraulic Institute’s latest report, pump systems account for approximately 20-25% of industrial energy consumption. By utilizing modern pump technologies, facilities can minimize downtime and ensure consistent fluid delivery, which is essential for maintaining operational efficiency. The reliability of pump systems reduces the risk of unexpected failures, leading to lower maintenance costs and minimized production disruptions.

Furthermore, a study published by the American Society of Mechanical Engineers (ASME) highlights that incorporating advanced monitoring and control systems to pump operations can improve reliability by up to 30%. These systems allow for real-time performance tracking, enabling operators to anticipate potential issues before they lead to failures. As industries shift toward automation, the capability to leverage data analytics further enhances the reliability of fluid delivery, ensuring that processes remain uninterrupted and products meet stringent quality standards. Adopting efficient pump systems can thus significantly impact operational performance by enhancing reliability in fluid management processes.

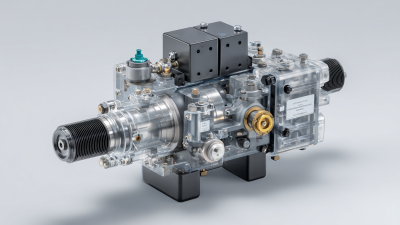

Versatility: Adapting Pump Systems for Various Fluid Types and Applications

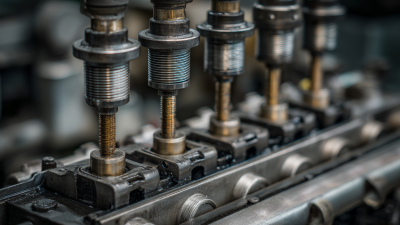

Pump systems are essential in fluid management across diverse industries, showcasing remarkable versatility in adapting to various fluid types and applications. From clean water pumping to handling viscous liquids and corrosive substances, these systems are engineered to cater to specific operational needs. For instance, centrifugal pumps are widely used for low-viscosity fluids, while positive displacement pumps excel in moving thick substances with precision. This adaptability allows industries to optimize processes and maintain efficiency regardless of the fluid characteristics.

Moreover, the ability to customize pump systems for specific applications enhances their effectiveness in fluid management. Industries such as food processing, chemical manufacturing, and wastewater treatment require pumps that can handle unique challenges. Specialized materials and designs, such as sanitary pumps for food and beverage applications or chemical-resistant pumps for aggressive fluids, ensure that these systems perform reliably and safely. By utilizing the appropriate pump technology, businesses can achieve superior fluid transfer and management, ultimately leading to improved productivity and reduced operational downtime.

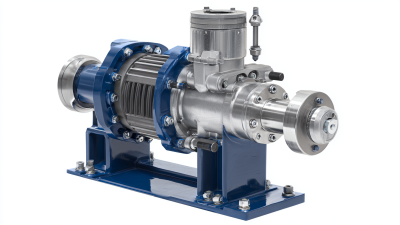

Maximized Energy Efficiency: How Pumps Optimize Resource Consumption

Pumps play a crucial role in efficient fluid management, significantly enhancing energy efficiency across various industries. According to the U.S. Department of Energy, pump systems account for about 20% of the global electrical energy consumption. By optimizing the operation of these systems, companies can achieve substantial energy savings. For instance, implementing variable speed drives can reduce energy consumption by up to 50% while providing precise control over fluid flow.

Moreover, modern pump technologies, including centrifugal and positive displacement pumps, are designed to operate at higher efficiencies, effectively minimizing operational costs. The Hydraulic Institute reports that implementing best practices in pump system design and operation can lead to energy savings of 20% to 50%. This not only contributes to lower energy bills but also reduces greenhouse gas emissions, aligning with sustainability goals viewed as crucial by industries worldwide.

As a result, investing in optimized pump systems not only supports cost efficiency but also positions organizations as environmentally responsible stakeholders.

Related Posts

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

Understanding the Benefits of Plunger Pumps in Industrial Applications

-

How to Optimize Your Injection Pumps for Maximum Efficiency and Performance

-

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.