Understanding the Benefits of Plunger Pumps in Industrial Applications

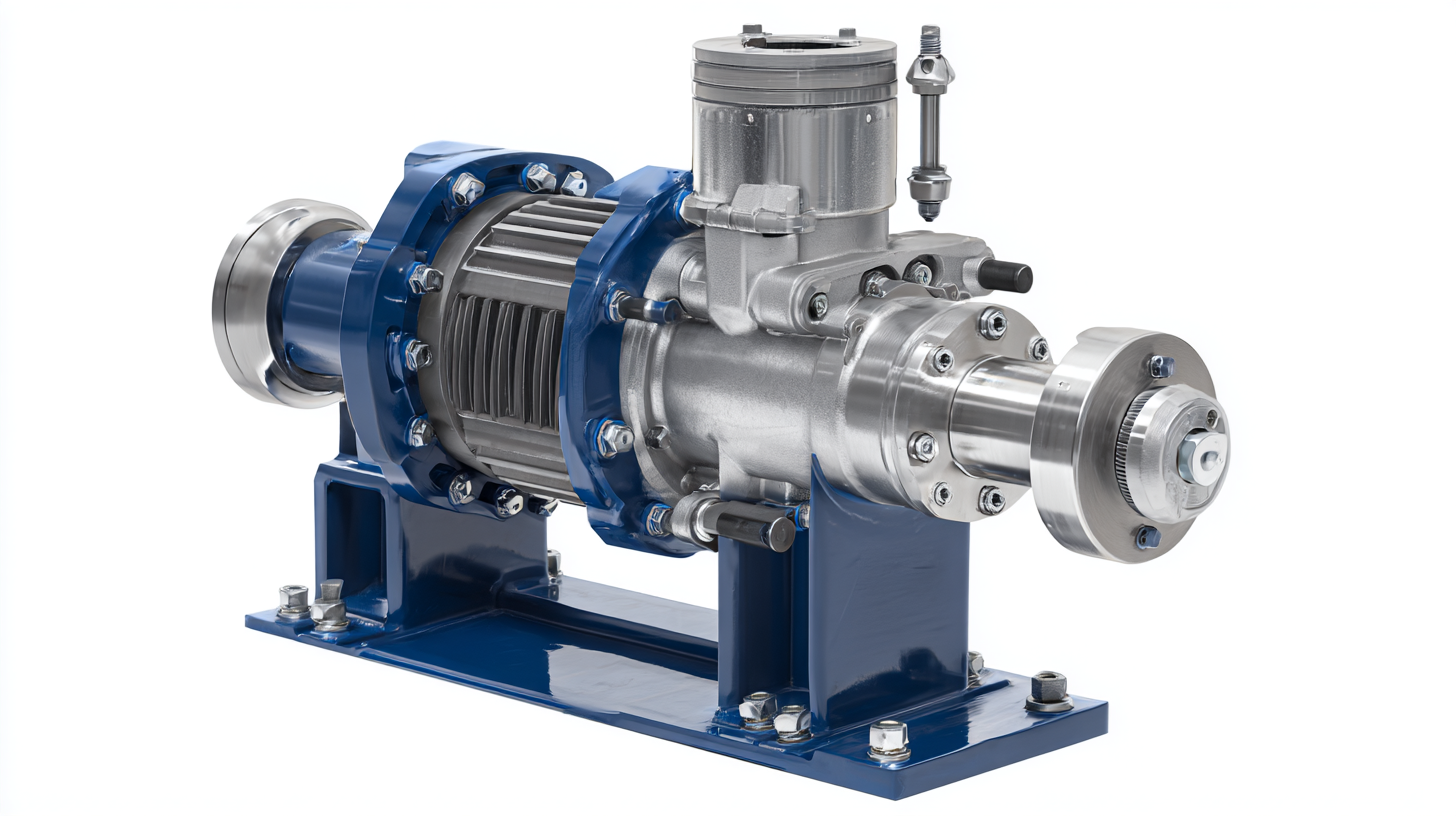

Plunger pumps are increasingly recognized for their efficiency and reliability in various industrial applications, playing a crucial role in fluid transfer processes across multiple sectors. According to a report by MarketsandMarkets, the global industrial pump market is projected to reach USD 80.9 billion by 2025, with plunger pumps facilitating enhanced pressure output and adaptability in demanding applications. These pumps excel in handling viscous liquids and high-pressure requirements, making them ideal for industries such as oil and gas, chemical processing, and agriculture. Furthermore, the ability of plunger pumps to maintain consistent performance under variable conditions has made them a preferred choice for many engineers and operators seeking to optimize their operations. Understanding the benefits of plunger pumps, therefore, is essential for businesses aiming to enhance their efficiency and productivity while ensuring reliable fluid management.

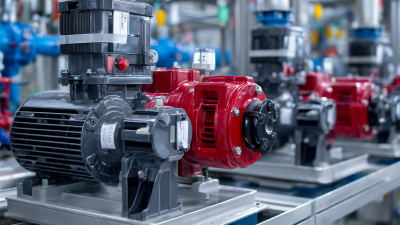

Advantages of Plunger Pumps Over Centrifugal Pumps in Heavy-Duty Applications

Plunger pumps offer significant advantages over centrifugal pumps, especially in heavy-duty industrial applications. Their design allows them to handle high-viscosity fluids and deliver consistent pressure, making them ideal for tasks that require reliability and precision. Unlike centrifugal pumps, which can struggle with variable flow conditions, plunger pumps maintain their performance even when faced with changes in discharge pressure or fluctuating fluid characteristics.

For those considering plunger pumps, here are some tips: First, assess the specific requirements of your application, including the type of fluid being pumped and the desired flow rate. This will help determine the right size and type of plunger pump to use. Additionally, consider the maintenance needs; while plunger pumps are robust, routine inspections can prevent costly downtime by addressing potential issues early.

Moreover, the ability of plunger pumps to handle abrasive materials makes them particularly suitable for sectors like mining and construction, where durability is crucial. By prioritizing pump selection based on the specific demands of your operation, you can ensure efficient performance and extend the lifecycle of your pumping equipment.

Understanding the Benefits of Plunger Pumps in Industrial Applications

| Dimension | Plunger Pumps | Centrifugal Pumps |

|---|---|---|

| Efficiency in High Viscosity Fluids | High efficiency | Lower efficiency |

| Pressure Handling Capability | Can handle high pressures | Limited to lower pressures |

| Pulsation Control | Can be designed for less pulsation | High pulsation |

| Maintenance Requirements | Higher maintenance needed | Generally lower maintenance |

| Cost of Operation | Higher due to components | Lower operational costs |

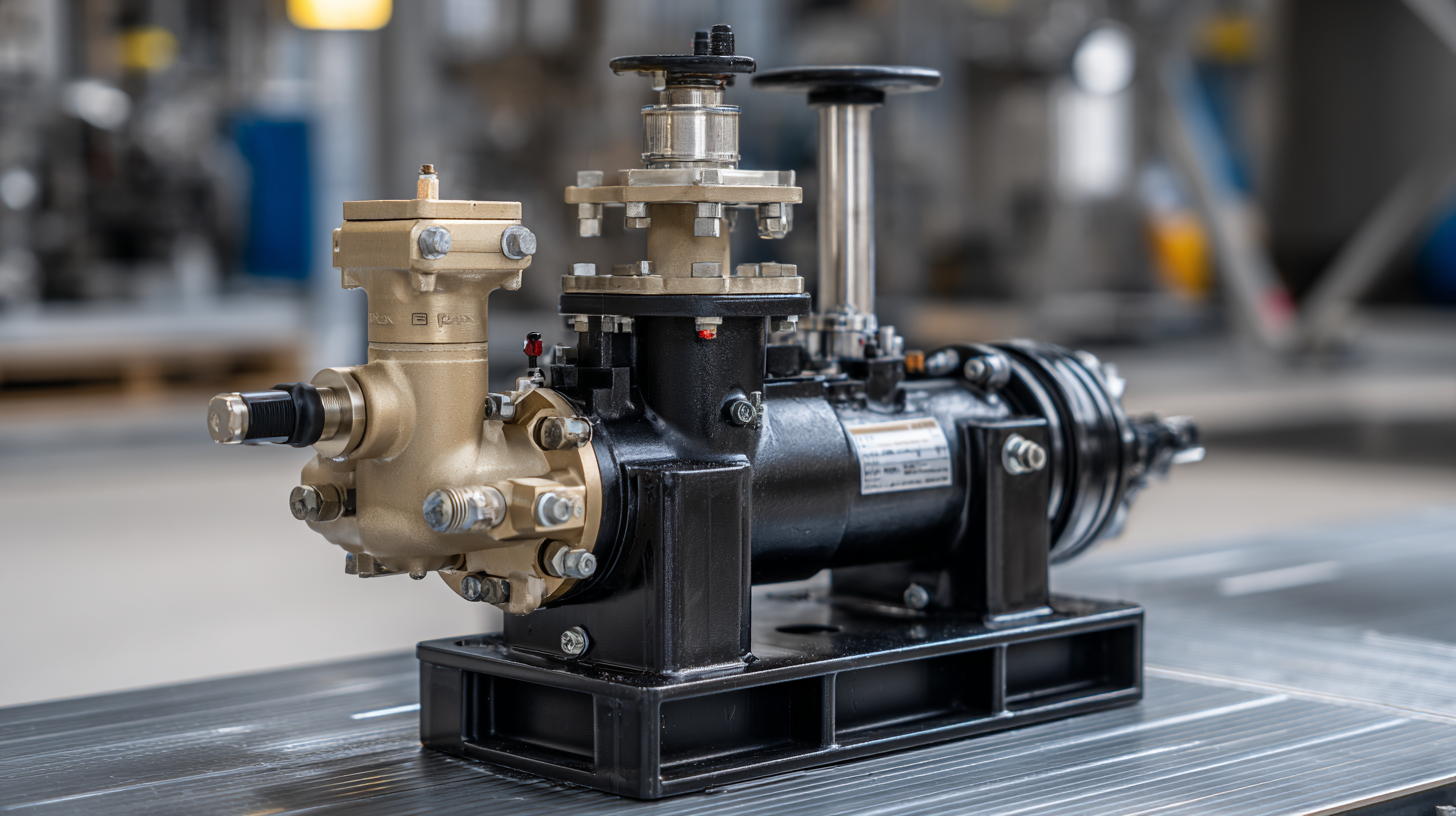

Key Industries Benefiting from Plunger Pump Technology: Oil & Gas and Chemical Processing

Plunger pumps have become essential in various industrial applications, particularly in the oil and gas and chemical processing sectors. The oil and gas industry benefits significantly from plunger pump technology due to its ability to handle high pressures and maintain consistent flow rates. These pumps are adept at transferring viscous fluids and slurries, making them ideal for tasks such as crude oil extraction and transportation. Their robust construction allows them to withstand the demanding conditions often found in drilling and extraction environments, ensuring reliability and efficiency.

In the chemical processing industry, plunger pumps play a crucial role in the precise handling of corrosive and abrasive chemicals. Their design allows for accurate metering and dosing, which is vital for maintaining product quality and consistency in manufacturing processes. Furthermore, the ability to operate at high pressures enables chemical manufacturers to optimize their production processes, leading to increased efficiency and reduced downtime. As industries continue to innovate, the versatility and durability of plunger pumps position them as a cornerstone technology in these critical sectors.

Understanding the Benefits of Plunger Pumps in Industrial Applications

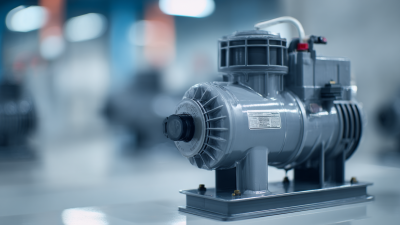

Efficiency Metrics: How Plunger Pumps Improve Operational Costs by up to 30%

Plunger pumps have emerged as a cornerstone of efficiency in industrial applications, particularly when it comes to optimizing operational costs. Recent studies have demonstrated that these pumps can enhance efficiency metrics by as much as 30%. This significant improvement is primarily due to their ability to maintain consistent flow rates while handling viscous and abrasive fluids, which are common in various industrial processes. By minimizing energy losses associated with fluid dynamics, plunger pumps not only extend equipment lifespan but also contribute to a decrease in overall energy consumption.

In addition to their direct benefits, plunger pumps also align well with emerging technologies like micro-combined heat and power (CHP) systems. Such systems aim to deliver heat and electricity simultaneously, making them highly effective for residential and light commercial buildings. The integration of reliable pumping solutions with these advanced CHP units can further enhance operational efficiencies, reinforcing the capabilities of modern industrial applications. According to industry reports, companies that adopt advanced pumping technologies in conjunction with energy-efficient systems are likely to see a substantial reduction in their operational costs, showcasing the tangible benefits that plunger pumps can provide in today’s competitive landscape.

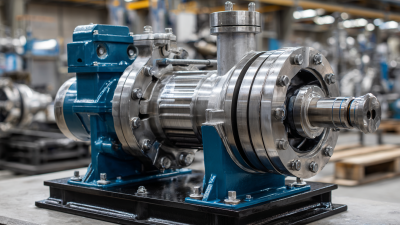

Reliability and Maintenance: Reducing Downtime with Plunger Pumps in Industrial Settings

Plunger pumps have emerged as a cornerstone in industrial applications due to their reliability and low maintenance requirements. According to a report by Grand View Research, the global positive displacement pump market is expected to reach $20 billion by 2025, highlighting the increasing adoption of technologies like plunger pumps that offer durability and efficiency. One major advantage of plunger pumps is their ability to operate under high pressures and varying flow rates, making them suitable for demanding applications in industries such as oil and gas, chemical processing, and wastewater treatment. This flexibility reduces the risk of operational downtime that can incur substantial costs.

To further enhance the reliability of plunger pumps, implementing a regular maintenance schedule is crucial. Studies indicate that proactive maintenance can improve equipment uptime by up to 30%, according to the Maintenance Management Institute. Simple tips such as routinely checking for leaks, monitoring pressure levels, and ensuring proper lubrication can significantly prolong the lifespan of the pump, leading to fewer unexpected breakdowns.

In addition, investing in condition monitoring technologies can provide real-time data on pump performance. This proactive approach not only helps identify potential issues before they escalate into costly repairs but also optimizes operational efficiency. By harnessing these strategies, industries can significantly reduce downtime, thereby enhancing productivity and profitability.

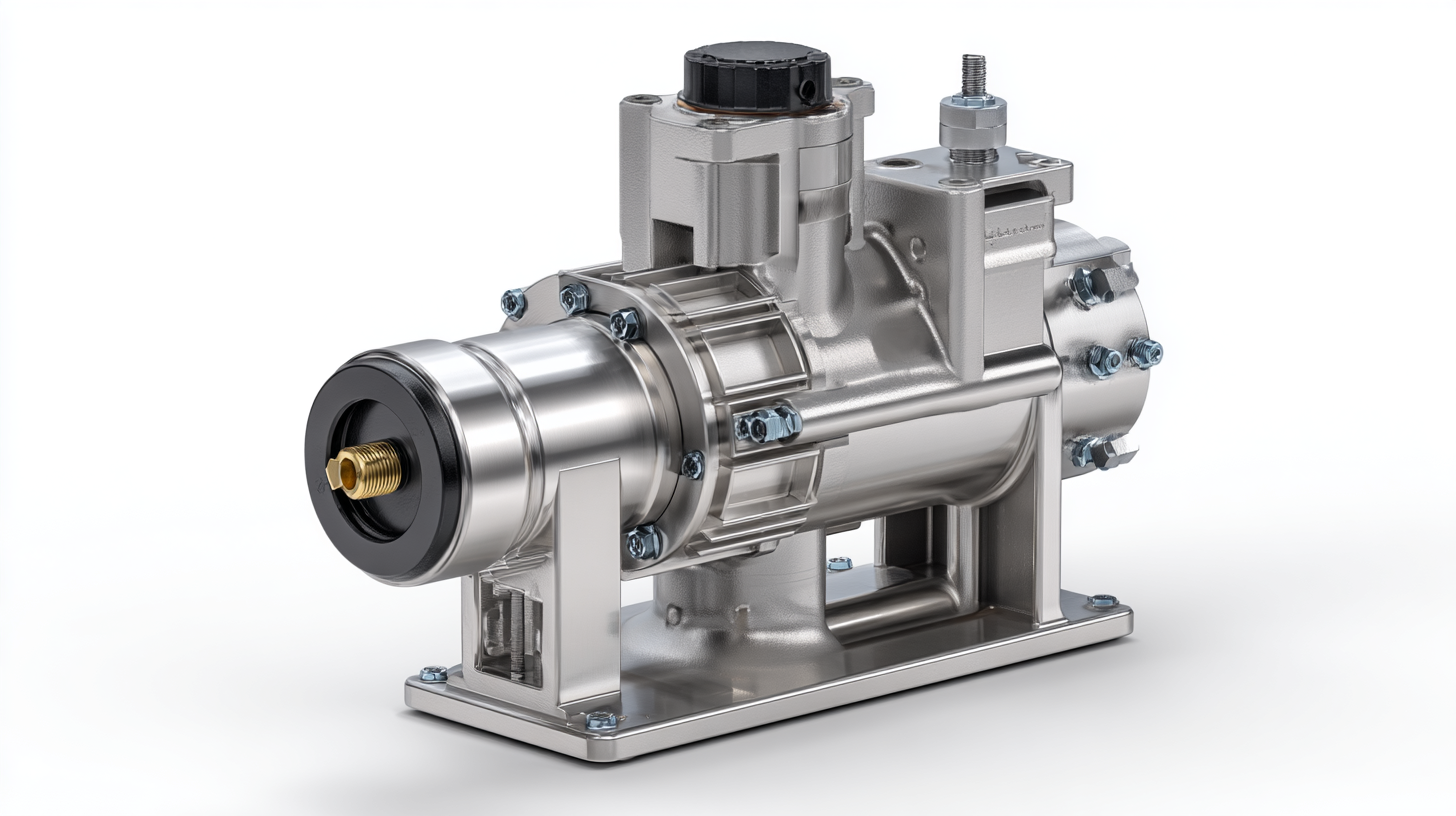

Comparative Analysis of Flow Rate and Pressure Performance in Plunger Pumps vs. Other Pump Types

Plunger pumps are renowned for their ability to deliver high pressure and precise flow rates, making them a favorite in various industrial applications. When comparing plunger pumps with other types, such as centrifugal or diaphragm pumps, the differences in performance become evident. Plunger pumps excel in situations requiring consistent high pressure, like in hydraulic systems or in the oil and gas industry, where pressurized fluids must be moved efficiently. Their flow rate remains steady across a wide range of operating conditions, an advantage that can significantly enhance system reliability.

Tips: When selecting a pump for your project, consider not just the required flow rate but also the specific pressure demands of your application. Understanding the nature of the fluid being pumped is vital, as viscous fluids may require a different approach. Regular maintenance can also maximize a plunger pump's lifespan and efficiency, ensuring optimal performance under varying operational stresses.

Additionally, while plunger pumps shine in high-pressure scenarios, they may not be as efficient with low-viscosity fluids compared to other pump types. It's crucial to evaluate the complete range of operational conditions to select the ideal pump type. Always factor in variables such as power consumption and wear rates, which could affect long-term operational costs.

Related Posts

-

What Makes a Plunger Pump Different from Other Pump Types

-

Understanding the Different Types of Motor Pumps and Their Applications in Various Industries

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

How to Choose the Right Electric Pumps for Your Business Needs

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.