Top 10 Benefits of Using Hydraulic Oil in Machinery?

Hydraulic oil plays a crucial role in machinery operation. According to John Smith, a renowned mechanical engineer in the hydraulic industry, “Choosing the right hydraulic oil can significantly improve machine performance.” This statement highlights the importance of selecting quality hydraulic oil for machinery efficiency.

Additionally, hydraulic oil enhances performance by reducing wear and tear. It lubricates the components and prevents overheating. However, some machines still face issues due to improper oil selection. Understanding the different types of hydraulic oil is vital for optimal usage. The right oil can ensure smoother operations and longer equipment life.

Yet, not all hydraulic oils are created equal. Some may seem cost-effective but can lead to bigger problems down the line. Decision-makers must assess their machinery needs carefully. The benefits of hydraulic oil are numerous, but neglecting to choose wisely could result in costly downtime. Investing in quality hydraulic oil is essential for machinery longevity and performance.

Benefits of Hydraulic Oil for Machinery Performance Enhancement

Hydraulic oil is crucial for improving machinery performance. Its unique properties enable efficient power transfer and smoother operation. According to a study by the International Fluid Power Society, using quality hydraulic oil can enhance system efficiency by up to 25%.

The lubrication qualities of hydraulic oil reduce friction in moving parts. This lowers wear and tear, extending the lifespan of machinery. A report from the American Society of Mechanical Engineers highlights that proper lubrication can reduce maintenance costs by 15% to 20%. For instance, using the right viscosity grade ensures optimal flow.

Improved Lubrication and Reduced Wear on Moving Parts

Hydraulic oil plays a crucial role in improving lubrication for machinery. It penetrates hard-to-reach areas effectively, ensuring that parts receive adequate lubrication. This can significantly reduce the friction between moving parts. Less friction means lower temperature levels during operation. High temperatures can lead to premature wear and tear, causing machinery to fail sooner than expected.

Additionally, hydraulic oil helps in minimizing contaminants. It keeps the internal parts cleaner, reducing harmful build-up. This cleanliness extends the lifespan of components. However, not all hydraulic oils are the same. Some may not offer the desired viscosity or lubricating properties. It’s essential to choose the right type for your machinery's needs. Over time, neglecting this may lead to serious issues, like seizures or malfunctions. Regular checks and maintenance remind users that even small lapses can have significant consequences.

Enhanced Energy Efficiency and Reduced Operating Costs

Hydraulic oil plays a crucial role in modern machinery, significantly enhancing energy efficiency. When machinery uses high-quality hydraulic oil, it operates more smoothly. The fluid dynamics allow for better power transfer. This efficiency can lead to notable savings on energy consumption. Even small improvements can add up over time, impacting bottom lines positively.

Reduced operating costs are another clear benefit. Better lubrication decreases wear and tear on components. Consequently, machines require less frequent maintenance. Downtime can be costly, especially in a competitive environment. With fewer repairs, budget allocations shift toward more productive areas. Yet, it’s essential to monitor oil quality diligently. Poor maintenance can negate these benefits.

Sustainability also gets a boost with hydraulic oil. Efficient machines consume less power, which indirectly contributes to reducing emissions. In an era where efficiency is not just ideal but necessary, these gains are invaluable. However, complacency can pose risks. Regular checks and mindful practices ensure that machinery remains in peak condition, maximizing both performance and cost-effectiveness.

Top 10 Benefits of Using Hydraulic Oil in Machinery

Superior Heat Management for Better Machinery Longevity

Hydraulic oil plays a crucial role in machinery by ensuring superior heat management. Heat generation is an inevitable part of machinery operation. When machinery runs, friction and pressure build up. If not managed, excess heat can lead to premature wear and tear. Studies show that effective heat control can extend machinery lifespan by up to 30%.

The right hydraulic oil can maintain optimal operating temperatures. It has high thermal stability, which prevents overheating. For instance, a report by the Machinery Lubrication Institute highlights that maintaining oil temperature below 50°C can enhance equipment durability. However, many operators overlook the oil's role in heat transfer. Instead, they focus solely on performance and efficiency. This oversight can be costly in the long run.

Proper maintenance of hydraulic oil is essential. Periodic analysis of oil can identify potential breakdowns or contamination. Recent data indicates that 75% of hydraulic system failures are related to poor fluid management. Regular monitoring and replacing of hydraulic oil can help avoid such issues. Striving for consistency in heat management is vital for machinery health. Yet, many still ignore this critical aspect.

Top 10 Benefits of Using Hydraulic Oil in Machinery

| Benefit | Description | Impact on Machinery |

|---|---|---|

| Superior Lubrication | Reduces friction and wear on moving parts. | Extends machinery life and enhances efficiency. |

| Improved Heat Transfer | Efficiently transfers heat away from critical components. | Prevents overheating and failure of machinery. |

| Corrosion Protection | Forms a protective barrier against rust and corrosion. | Increases the durability of metal components. |

| Stability Under Pressure | Maintains viscosity and performance under high pressure. | Ensures consistent operation of hydraulic systems. |

| Reduced Maintenance Costs | Minimizes wear and tear, leading to lower repair costs. | Improves overall operational efficiency. |

| Enhanced Efficiency | Optimizes power transmission and performance. | Boosts productivity and reduces energy consumption. |

| Noise Reduction | Dampens sound produced by moving parts. | Creates a quieter working environment. |

| Compatibility with Various Materials | Safe for use with elastomers and metals. | Prevents damage to seals and components. |

| Environmentally Friendly Options | Bio-based and less harmful to the environment. | Supports sustainability initiatives. |

| Longer Oil Life | Resists breakdown and maintains performance longer. | Reduces frequency of oil changes, saving time and money. |

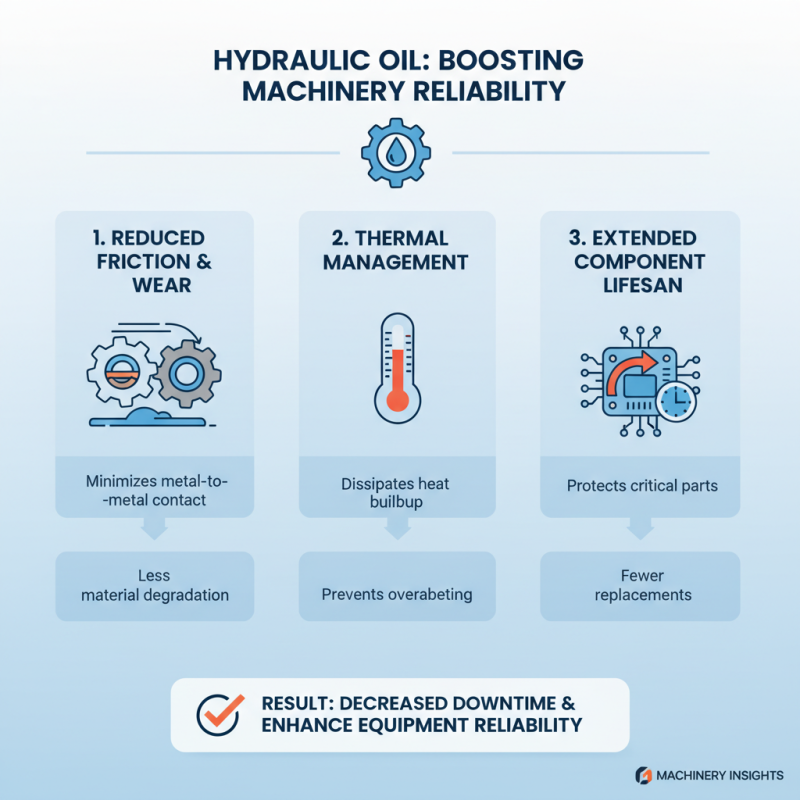

Increased Equipment Reliability and Reduced Maintenance Intervals

Hydraulic oil plays a crucial role in machinery. It enhances equipment reliability significantly. This reliability stems from the oil's ability to minimize friction and wear. With reduced friction, machines experience less heat buildup. This leads to longer life for critical components. Operators often see a marked decrease in downtime as a result.

Reduced maintenance intervals are another major benefit. Using high-quality hydraulic oil means fewer oil changes. Less frequent maintenance saves time and costs. Workers can focus more on productive tasks instead of repairs. However, some may still neglect regular checks. This oversight can lead to unexpected failures. It's essential to balance convenience with diligent upkeep.

Additionally, choosing the right viscosity is not always straightforward. Many factors influence performance. Environmental conditions, temperature fluctuations, and machine design all matter. A wrong choice could negate the benefits of hydraulic oil. It's a reminder to assess not just the machinery, but also the oil used. This attention to detail can enhance reliability and reduce maintenance gaps.

Related Posts

-

Top 10 Best Pressure Pumps for Every Application in 2026?

-

Top 10 Pressure Pumps for Ultimate Efficiency in 2023

-

Why Are Industrial Pumps Essential for Manufacturing Efficiency?

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

-

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.