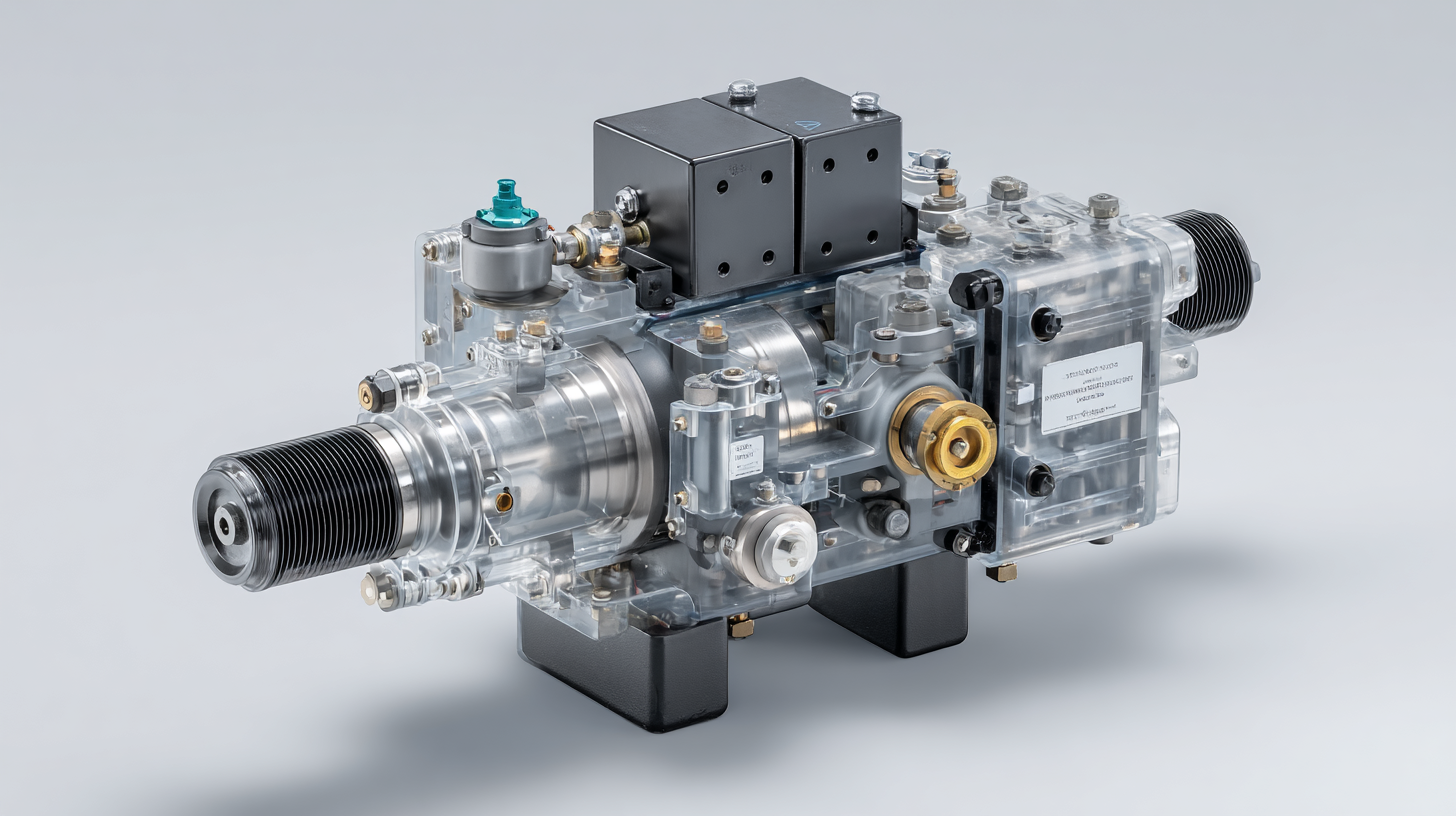

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

In recent years, the industrial sector has increasingly recognized the advantages of electric diaphragm pumps, which have become essential components in various applications ranging from chemical processing to wastewater management. According to a report by MarketsandMarkets, the global diaphragm pump market is projected to reach USD 5.28 billion by 2026, indicating a compound annual growth rate (CAGR) of 6.2% from 2021. This growth is driven by the pumps' efficiency, reliability, and versatility, particularly in handling aggressive fluids and providing precise flow control.

Electric diaphragm pumps offer significant benefits over their mechanical counterparts, including reduced maintenance costs, lower energy consumption, and minimal risk of leaks, which are critical factors for industries aiming to enhance sustainability and operational efficiency. As such, understanding the benefits of electric diaphragm pumps in modern industrial applications is more important than ever for decision-makers looking to optimize their processes and ensure compliance with environmental regulations.

How to Identify the Ideal Applications for Electric Diaphragm Pumps in Industry

Electric diaphragm pumps have transformed modern industrial applications with their versatility and efficiency. To identify the ideal applications for these pumps, one must consider various factors, including the nature of the fluid being pumped, pressure requirements, and environmental conditions. According to a recent report by Grand View Research, the global market for diaphragm pumps was valued at approximately $1.2 billion in 2022 and is expected to grow at a CAGR of 5.3% through 2030, highlighting the increasing reliance on these systems across various sectors.

Electric diaphragm pumps have transformed modern industrial applications with their versatility and efficiency. To identify the ideal applications for these pumps, one must consider various factors, including the nature of the fluid being pumped, pressure requirements, and environmental conditions. According to a recent report by Grand View Research, the global market for diaphragm pumps was valued at approximately $1.2 billion in 2022 and is expected to grow at a CAGR of 5.3% through 2030, highlighting the increasing reliance on these systems across various sectors.

For industries dealing with corrosive or viscous fluids, electric diaphragm pumps are particularly advantageous. Their ability to handle abrasive materials without compromising performance makes them suitable for chemical manufacturing, mining, and wastewater treatment. Tips for selecting the right pump include assessing the chemical compatibility of the materials, determining the required flow rate, and evaluating the need for portability.

When considering the ideal applications, it’s also essential to factor in energy efficiency. Studies show that electric diaphragm pumps can achieve energy savings of up to 40% compared to traditional pumps. Implementing these pumps not only optimizes operational efficiency but also reduces overall energy consumption, aligning with modern sustainability goals.

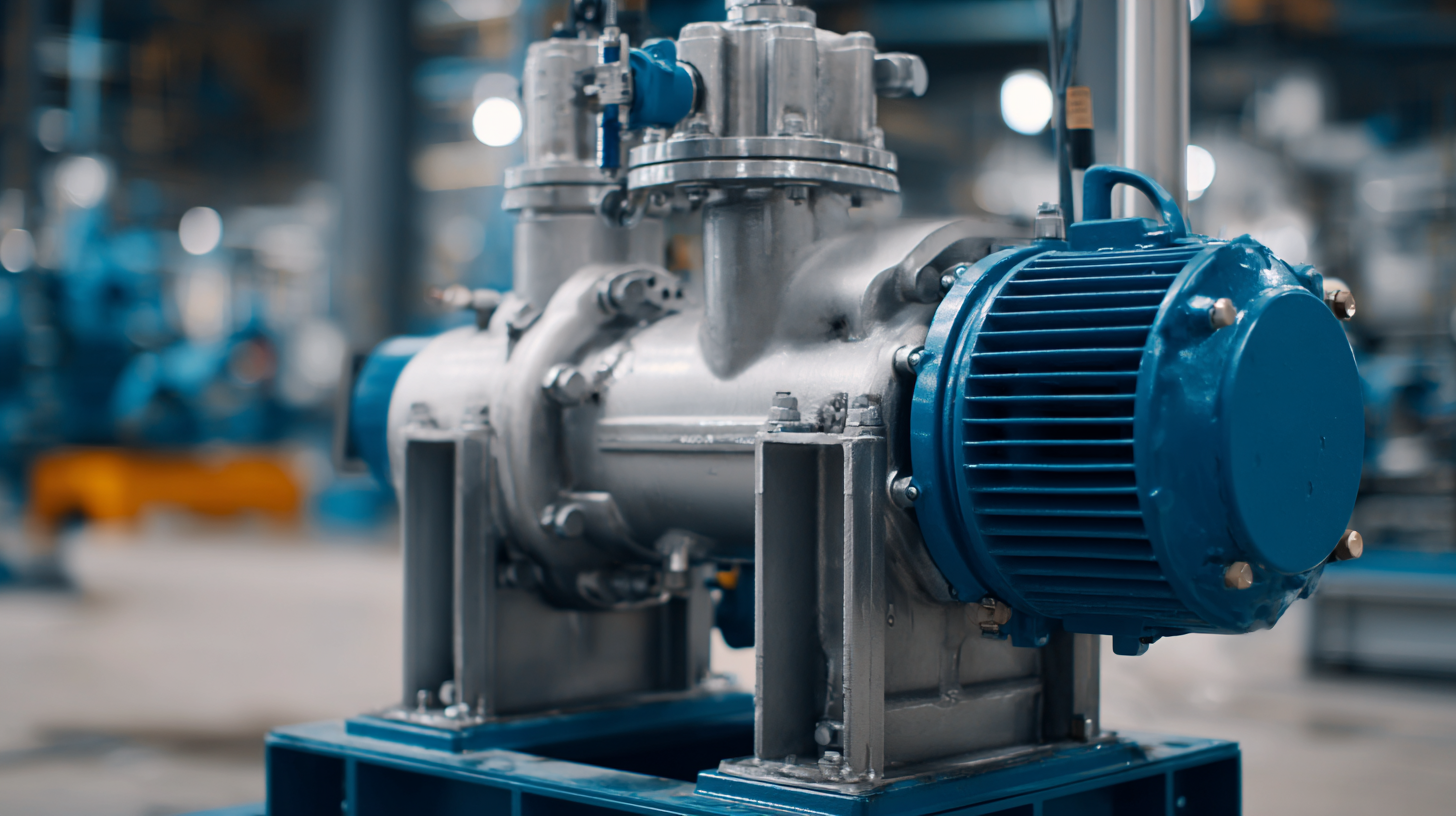

How to Compare Electric Diaphragm Pumps to Traditional Pumping Solutions

Electric diaphragm pumps have gained significant traction in modern industrial applications due to their distinctive advantages over traditional pumping solutions. When comparing these pumps to conventional options, one key aspect to consider is efficiency. Electric diaphragm pumps offer superior volumetric efficiency and can handle a variety of liquids, including corrosive or viscous substances, without compromising performance. This versatility aligns well with industries requiring reliable fluid transfer solutions.

**Tips**: When selecting an electric diaphragm pump, assess the application's specific requirements such as flow rate, pressure range, and chemical compatibility. It's also important to evaluate the maintenance needs of the pump; many electric diaphragm models are designed for low maintenance, enhancing their value in long-term operational scenarios.

Another significant factor is energy consumption. Electric diaphragm pumps generally consume less energy than traditional pumps, leading to reduced operational costs and a smaller environmental footprint. Moreover, the ability to control flow rates electronically allows for greater precision and adaptability in various industrial contexts.

**Tips**: Always consider the total cost of ownership when comparing pump options. Although electric diaphragm pumps may have a higher initial cost, their energy efficiency and lower maintenance can lead to substantial savings over time.

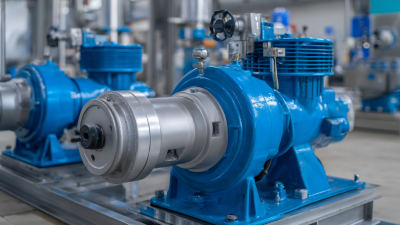

How to Maximize Efficiency and Performance with Electric Diaphragm Pumps

Electric diaphragm pumps have emerged as a crucial solution for modern industrial applications, especially in sectors that require precise fluid handling and efficiency. The global diaphragm pump market was valued at approximately $6.27 billion in 2023, with projections indicating it could reach $9.97 billion by 2032. This growth reflects an increasing demand for more efficient pumping solutions that reduce operational costs and improve reliability.

To maximize the efficiency and performance of electric diaphragm pumps, industrial users are encouraged to focus on recent innovations in pump technology. For instance, the latest electric diaphragm pumps are designed specifically for energy efficiency, which not only lowers the carbon footprint but also results in significant cost reductions. These advancements enable better handling of demanding applications, such as chemical transfers and slurry processing, thereby enhancing overall productivity in various manufacturing processes. Additionally, features like improved priming capabilities for chemical applications further underscore their versatility and effectiveness in modern industrial settings.

How to Maintain and Troubleshoot Electric Diaphragm Pumps for Longevity

Electric diaphragm pumps are becoming increasingly prevalent in modern industrial applications due to their versatility and efficiency. To fully realize the benefits of these pumps, proper maintenance and troubleshooting practices are essential. Regular inspections should focus on checking for leaks, ensuring proper electrical connections, and monitoring the diaphragm's integrity. Keeping a consistent maintenance schedule can significantly extend the pump's lifespan and help avoid costly downtimes.

When issues arise, troubleshooting can often be simplified by following a systematic approach. Start by verifying the power supply and connections; electrical problems are a common failure point. If the pump is not functioning as expected, examine the diaphragm for signs of wear or damage; this component is crucial for maintaining functionality. Additionally, consider the fluid compatibility and pressure settings, as improper specifications can lead to failures. By adhering to these maintenance guidelines and proactively addressing potential issues, users can ensure their electric diaphragm pumps operate effectively and efficiently, contributing to overall industrial productivity and performance.

How to Evaluate the Cost-Effectiveness of Electric Diaphragm Pumps in Operations

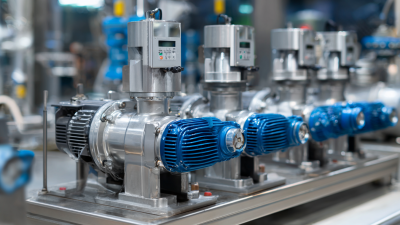

Electric diaphragm pumps have emerged as a vital component in modern industrial applications due to their unique advantages, particularly in terms of cost-effectiveness. When evaluating these pumps, it is crucial to consider both initial investment and long-term operational costs. The recent introduction of a new electric diaphragm pump model highlights how advancements can lead to significant improvements in efficiency and uptime. These factors not only enhance productivity but can also lead to considerable savings over time.

Tips for evaluating cost-effectiveness include analyzing the total cost of ownership, which encompasses maintenance, energy consumption, and potential downtime. Additionally, consider the pump's compatibility with existing systems and its impact on workflow. Investments in high-efficiency pumps may have a higher upfront cost, but the return on investment is realized through reduced operational costs and energy savings.

When assessing the specific needs of your operations, it is essential to compare different models and their features. Look for energy efficiency ratings, durability, and the availability of technical support. By taking these factors into account, businesses can choose electric diaphragm pumps that will provide optimal performance and value over their operational lifecycle.

Related Posts

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

What is the Functionality Behind Liquid Pumps in Modern Industries

-

Liquid Pump Innovations and Industry Trends Highlighted at 2025 China Import and Export Fair

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.