2026 Top Plunger Pump Innovations and Trends to Watch Out For?

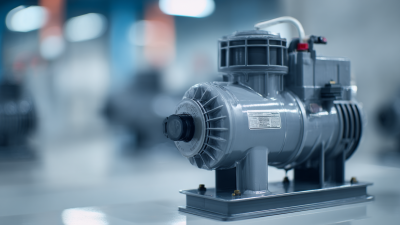

In the world of industrial pumping, innovations in plunger pumps are reshaping efficiency and reliability. Experts believe that understanding these trends is crucial. Dr. Emily Carter, a leading authority in fluid dynamics, states, "The evolution of plunger pumps is vital for enhancing performance in various applications."

As we look toward 2026, several key advancements are on the horizon. These include improved materials that enhance durability and efficiency. Enhanced designs will likely reduce wear and tear, critical factors in many industries. However, not all trends are promising; some innovations may not live up to expectations.

The potential for automation in plunger pump technology is exciting but also raises questions. Will automation truly lead to cost savings? Or will it create complexities that complicate operations? The future of plunger pumps looks vibrant, yet caution is necessary. Understanding both the bright prospects and possible pitfalls is essential for stakeholders.

Emerging Technologies in Plunger Pump Design for 2026

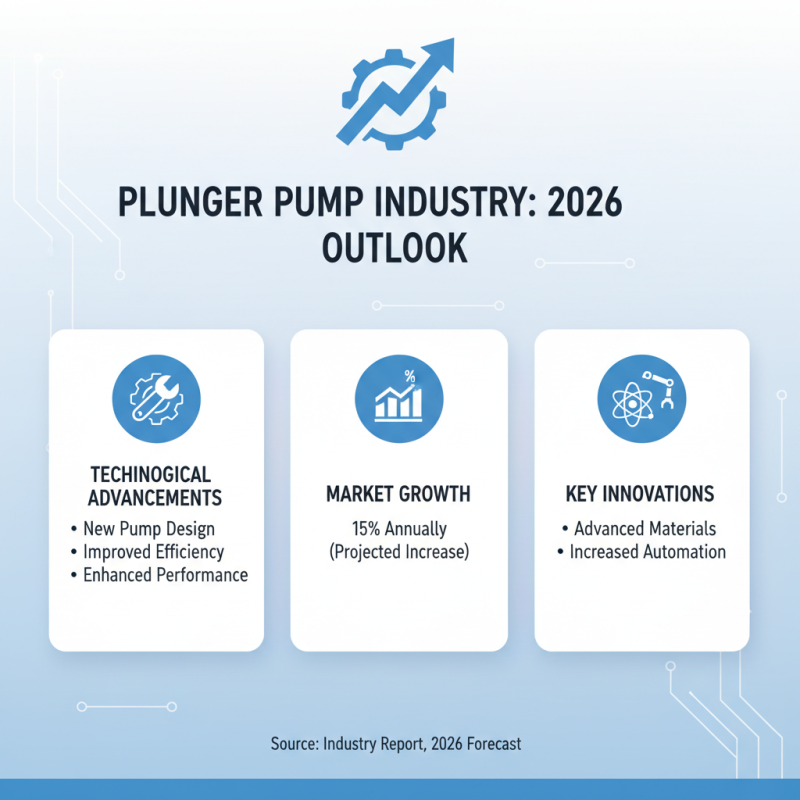

The plunger pump industry is set for significant advancements in 2026. Emerging technologies are changing pump design, efficiency, and performance. According to a recent industry report, the market for plunger pumps is expected to grow by 15% annually. Innovations focus on materials and automation.

One key trend is the use of advanced materials. Lightweight composites are gaining popularity, helping reduce wear and improve lifespan. However, these materials can be expensive. Companies must balance costs with the benefits they provide. Another important development is the integration of IoT. Smart pumps allow for real-time monitoring and maintenance alerts, which can prevent failures. Yet, cybersecurity concerns loom large. Companies will need robust protections against potential breaches.

The push for energy efficiency continues to rise. According to the International Energy Agency, up to 30% of a facility's energy costs come from pumping systems. Enhanced designs focus on reducing energy waste, but the transition requires upfront investment. Not all companies may be prepared. Awareness of these trends will be crucial for stakeholders in the plunger pump market. Each innovation presents both opportunities and challenges that require careful consideration.

Sustainability Trends in Plunger Pump Materials and Manufacturing

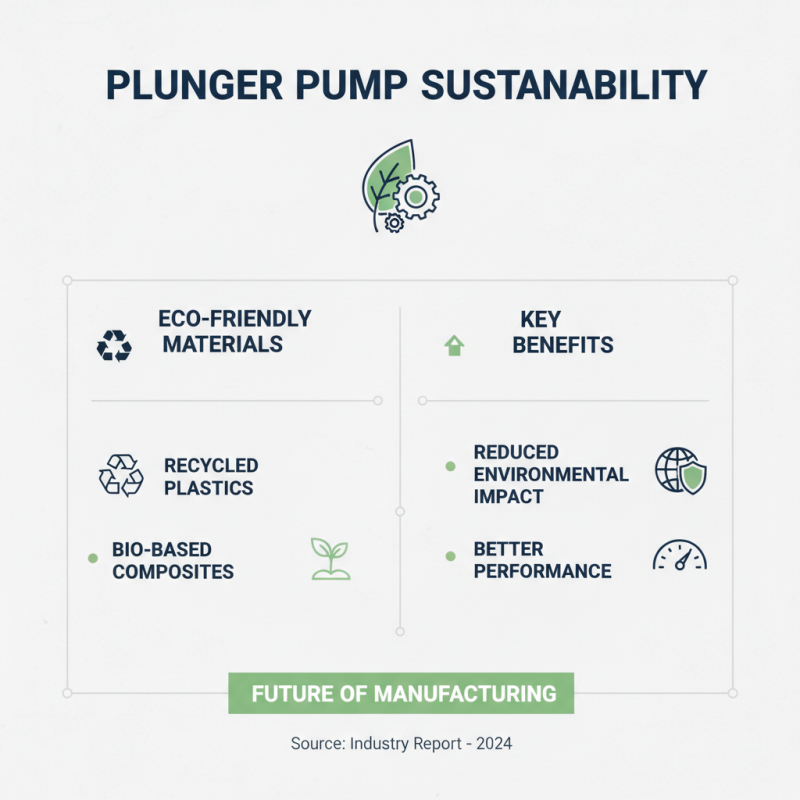

Sustainability is becoming a key focus in plunger pump materials and manufacturing. Many manufacturers are exploring eco-friendly materials. These materials reduce environmental impact and offer better performance. For example, recycled plastics and bio-based composites are gaining traction.

The manufacturing processes also need attention. Energy-efficient methods can cut down waste and emissions. Some companies are investing in renewable energy for their operations. It’s a step in the right direction, yet challenges remain. Not all manufacturers are ready to make these changes.

Furthermore, the industry should not overlook its carbon footprint. The transition to sustainable practices is often slow. Continuous innovation is necessary to drive significant change. Without a commitment to sustainability, the benefits of new materials and methods may not be fully realized.

Smart Integration: IoT and Automation in Plunger Pump Systems

The integration of IoT and automation in plunger pump systems is transforming the industry. Smart technology enables real-time monitoring. This results in improved efficiency and reduced downtime. A recent report indicates that IoT adoption in industrial equipment can increase operational efficiency by up to 30%.

Automation reduces manual intervention. Workers can focus on complex tasks rather than routine checks. This shift not only boosts productivity but also enhances safety. A survey noted that 60% of companies are considering automated systems for improving operational workflows.

Tips for implementation: Ensure proper training for employees on new systems. Regular updates to software are crucial. Think about integrating predictive maintenance features to reduce unplanned outages. Smart technology is powerful but may require adjustments. Being open to this change can yield significant long-term benefits for your operations.

Efficiency Improvements: Energy-Saving Features in Plunger Pumps

The focus on energy-saving features in plunger pumps reflects a significant shift in the industry. According to a recent report from the International Energy Agency, efficiency improvements can lead to up to 30% less energy consumption. This is a game changer. Manufacturers are now incorporating advanced materials that enhance durability and reduce friction. These changes lead to lower operating costs.

Innovative designs are bringing new technologies. For example, variable speed motors are becoming common. They adjust to the specific needs of the application. This means less waste and more control over energy use. However, not all manufacturers have adopted these technologies. Some continue to use outdated designs, which hamper efficiency.

Additionally, better seals and advanced hydraulic systems are on the rise. They minimize leakage and increase power output. But implementation can be slow. Training is essential for operators to utilize these advancements effectively. The market must address this gap. Energy efficiency should be a priority, but the transition can be challenging.

Market Dynamics: Key Players and Innovations in Plunger Pump Industry

The plunger pump industry is experiencing exciting changes. More companies are focusing on energy efficiency. This shift not only saves costs but also benefits the environment. In recent years, the move toward renewable energy sources has pushed innovation forward.

Manufacturers are integrating smart technology into their pumps. This makes monitoring performance easier and reduces downtime. Sensors can detect issues before they become serious. Predictive maintenance is becoming a trend. Companies are investing in artificial intelligence for better performance analysis.

However, challenges remain. Some companies lag in adopting new technologies. Resistance to change can slow progress. The gap between early adopters and traditional manufacturers is widening. This divide may affect market competitiveness. Industry players must reflect on these dynamics to thrive in a rapidly evolving landscape.

2026 Top Plunger Pump Innovations and Trends to Watch Out For

| Innovation/Trend | Description | Impact on Market | Potential Challenges |

|---|---|---|---|

| Smart Pump Technology | Integration of IoT for real-time monitoring and predictive maintenance. | Improves efficiency and reduces downtime. | High initial investment and requirement for skilled personnel. |

| Eco-friendly Materials | Use of sustainable and biodegradable materials in pump construction. | Aligns with global sustainability trends and regulations. | Potential regulatory hurdles and material performance issues. |

| Variable Frequency Drives (VFDs) | Advanced control technologies to optimize pump operation. | Enhances energy efficiency and reduces operational costs. | Complex installation and integration processes. |

| Modular Pump Designs | Designs that allow for easy upgrades and customization. | Increases product lifespan and flexibility in applications. | Higher manufacturing costs and complexity. |

| Digital Twin Technology | Creation of digital replicas for monitoring and analysis. | Facilitates enhanced operational insights and performance optimization. | Data security concerns and technical challenges in implementation. |

Related Posts

-

What Makes a Plunger Pump Different from Other Pump Types

-

Understanding the Benefits of Plunger Pumps in Industrial Applications

-

How to Choose the Right Electric Pumps for Your Business Needs

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

Understanding the Role of Chemical Pumps in Enhancing Water Treatment Efficiency

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.